Search

Search

Search

Search

iCruise® Intelligent Rotary Steerable System drills curve section in 17 Hours

Download PDFUnconventionals

Optimize the drilling program using the iCruise RSS

Eddy County, Texas

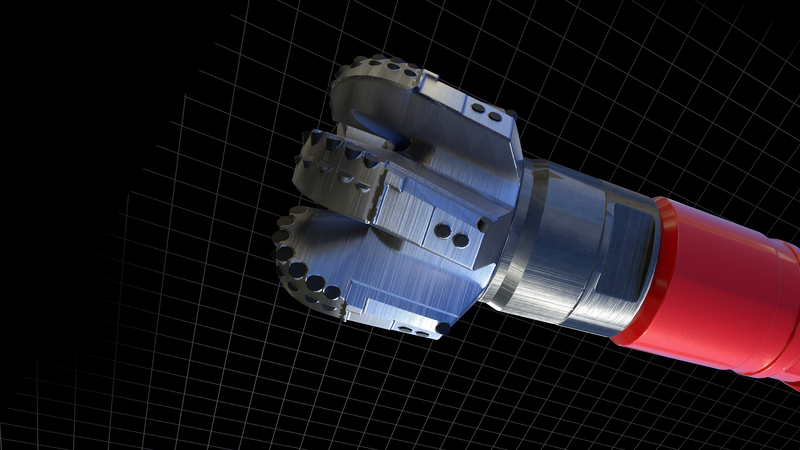

An operator drilling in the Delaware Basin completed their fastest curve section in the area, having collaborated with the Halliburton Sperry Drilling team to optimize the drilling program. It was decided to drill this well section utilizing the 4.75-in. iCruise® intelligent rotary steerable system (RSS), matched with a 6.75-in. GeoTech® GTi64D drill bit.

Multiple technologies were combined to improve drilling performance over offset wells in the region:

Reduction in drilling time

Maximum DLS (⁰/100’)

Average ROP (ft/hr)

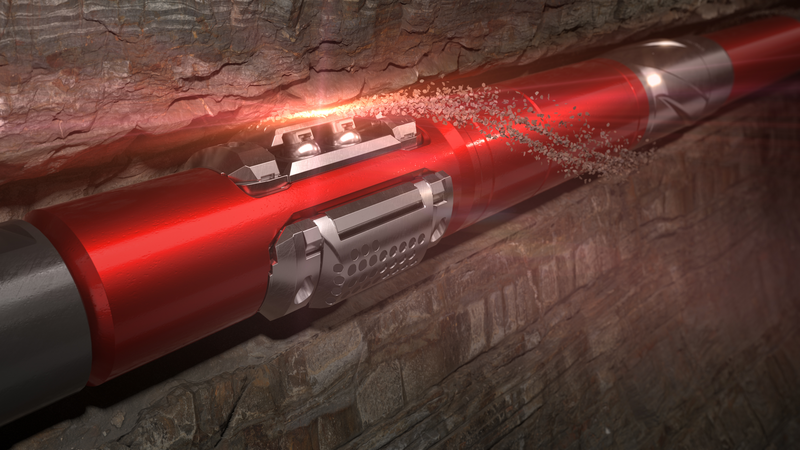

Reduce well time through fast drilling, fast tripping time and quicker casing drill outs.

GeoTech® matrix and steel body drill bits are customized to deliver performance across all drilling applications.

Halliburton rotary steerable systems are engineered with advanced technologies to reduce well time and accurately place well in reservoir.

Halliburton delivers superior drilling performance to reduce time to first oil, enhance reservoir knowledge, and maximize production.

DatCI is a powerful service platform used to optimize bit and drilling performance through in-depth planning, bit design, and post-well evaluation.