Search

Search

Search

Search

DFG™ DrillAhead® hydraulics modeling software optimizes hole cleaning in long lateral

Download PDFMature Fields

Avoid ultra-fine drill solids buildup while drilling a 9,000-foot lateral

Onshore Middle East

An operator in the Middle East planned to drill a 9,000-foot (2743-meter) lateral in a reservoir known for generating very fine drill solids that could impair hole cleaning and increase torque. Before deploying a new rotary steerable system (RSS) to drill this lateral section, the operator wanted to confirm that the target rates of penetration (ROPs) would not cause excessive cuttings loading in the wellbore. During a drill-well-on-paper exercise, the proposed drilling parameters were used to simulate and analyze hole cleaning effectiveness.

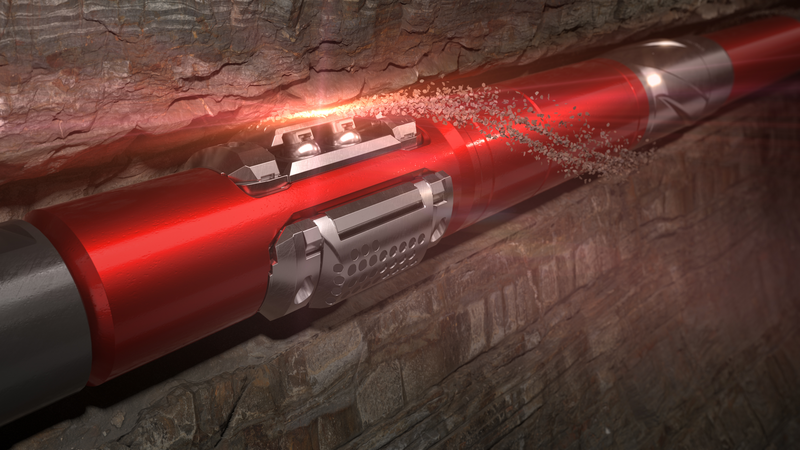

The 8.5-inch lateral would be drilled with an invert emulsion fluid (IEF) with densities ranging from 63 to 69 pcf (8.6 to 9.2 ppg). Maintaining a stable mud rheology and providing efficient hole cleaning would be critical during the trial of a new RSS bottomhole assembly (BHA).

On a previous well, the high concentration of ultra-fine drill solids (primarily < 8 micron) entrained in the IEF had led to higher base oil consumption and difficulty maintaining desired mud properties while drilling the long lateral. Since the operator wanted to ensure that this did not occur during the RSS trial well, the Halliburton Baroid plan focused on the following objectives:

Working closely with the customer, the Baroid team used the proven DrillAhead® module included in the DFG software to analyze hole cleaning effectiveness while drilling with the new RSS BHA, drilling parameters, and target ROP, which included:

DrillAhead simulations indicated that an average ROP of 75 feet/hour (22.86 meters/hour) could be achieved in the 8.5-inch lateral while maintaining good hole cleaning.

While drilling, DFG DrillAhead software analysis was performed four times daily to ensure that drilling parameters could be adjusted on the fly as needed. Maximum allowable cuttings loading was set at 3 percent in any annular section. All simulation results were presented to the operator’s rig supervisor and drilling team.

Average rate of penetration (ft/hr) - first well

Average rate of penetration (ft/hr) - second well

On the first well, an average ROP of 70–75 feet/hour (21.33–22.86 meters/hour) was achieved consistently. The same approach was employed on the second well with similar reservoir conditions and drilling parameters. In this case, the average ROP was 110 feet/hour (33.53 meters/hour), which was the second-best ROP in the field for wells drilled with similar BHA components. The cuttings loading remained below the 3 percent limit throughout the lateral section, and ECD and torque values – monitored at the real-time operations center – were reported to be normal on both wells.

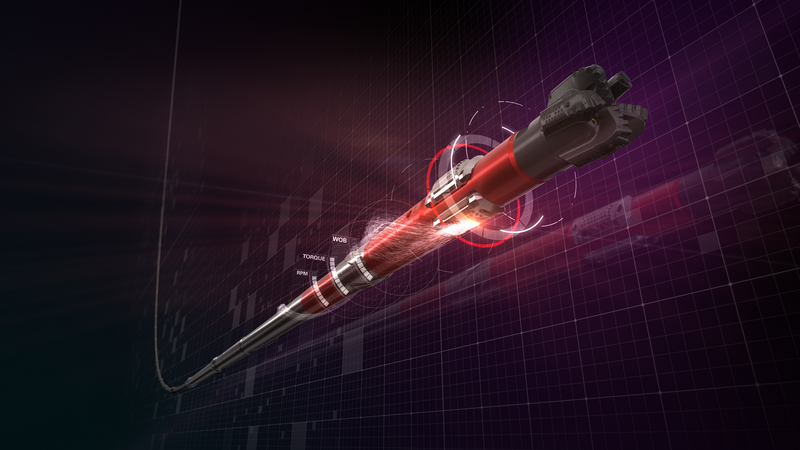

The iCruise® intelligent RSS drilled the long lateral successfully, eliminating delays due to excessive cuttings loading or pack-offs.

Halliburton rotary steerable systems are engineered with advanced technologies to reduce well time and accurately place well in reservoir.

Reduce well time through fast drilling, fast tripping time and quicker casing drill outs.

Automation-enabled platform designed specifically for longer well applications in harsh environments.

The Halliburton Geo-Pilot® rotary steerable systems (RSS) is designed to deliver unprecedented speed and precise steering.