Search

Search

Search

Search

Engineered to excel in dynamic well conditions, it provides both a flexible extended operating range and significantly longer run life

talk to an expertTiger Shark® pumps adapt to changing well production, improving operating range and run life. They are designed for maximum flexibility in conventional, unconventional, and gassy wells while addressing extremely abrasive deep wells with high discharge pressure.

750 series pump for mulitple ESP applications

The Tiger Shark® 750 series pump was developed to excel in geothermal, water well, carbon capture, utilization and storage (CCUS), and mining applications.

Leveraging in-house hydraulics simulations and computational fluid dynamics (CFD), our expert engineers developed a pump with the industry’s highest efficiency rating.

Read data sheetour pumps are Built to Last

Tiger Shark pumps exemplify robust engineering, setting the standard for reliability and longevity.

Our pumps have consistently exceeded expectations, proving our unwavering commitment to quality and service and enhance production efficiency.

Tiger Shark pumps are a reliable pump for maximizing well productivity and optimizing production.

Recent technological advancements address challenges in both conventional and unconventional wells, including the need to pump significant amounts of abrasive material and handle fluids that exceed normal pressure operating limits.

* Application-specific option

CASE STUDY: ROCKY MOUNTIANS REGION

Abrasion protection in deep, high-pressure, and highly abrasive well saves operator over $150,000 in operating expense.

See case studyTiger Shark pumps are highly dependable, enhancing performance in deeper wells where higher discharge pressure normally occurs. These specialized advancements have resulted in first-rate pump performance in extremely abrasive and high-pressure wells.

Specialty coatings protect pumps from harsh downhole conditions common in unconventional wells, while our novel intake adds further protection from formation fines and frac sand.

Summit ESPs Tiger Shark pumps are our go-to choice for reliability and longevity in the field. They consistently outperform and outlast, making them an ESP industry favorite.

Case Study: Alaska

A side-by-side comparison with standard pump diffusers show Erosion Buster® design nearly doubles Tiger Shark® II pump run life.

See case study

DuraHard coatings protect against friction, abrasive, and corrosive conditions, providing longer pump run life.

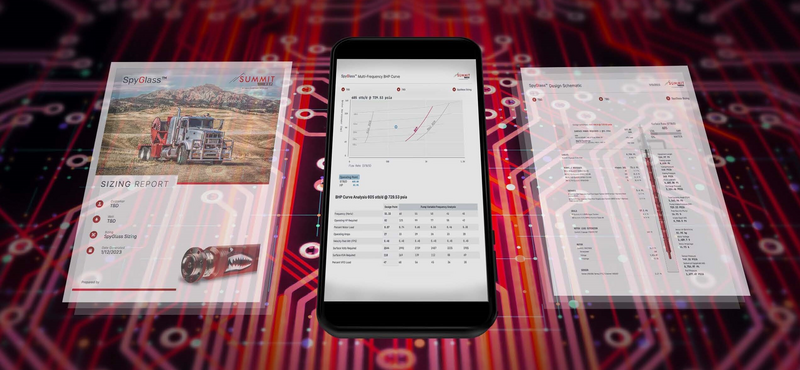

Cloud-based application for designing and assessing electric submersible pump performance.

Halliburton's high-efficiency submersible borehole and surface pump technology for super-heated water and steam management in geothermal energy production.

Summit ESP® submersible borehole and surface pumps for mining operations.

Summit ESP® NSF-certified electric submersible pumping systems for municipal water applications facilitate the supply of clean drinking water for the public.