Search

Search

Search

Search

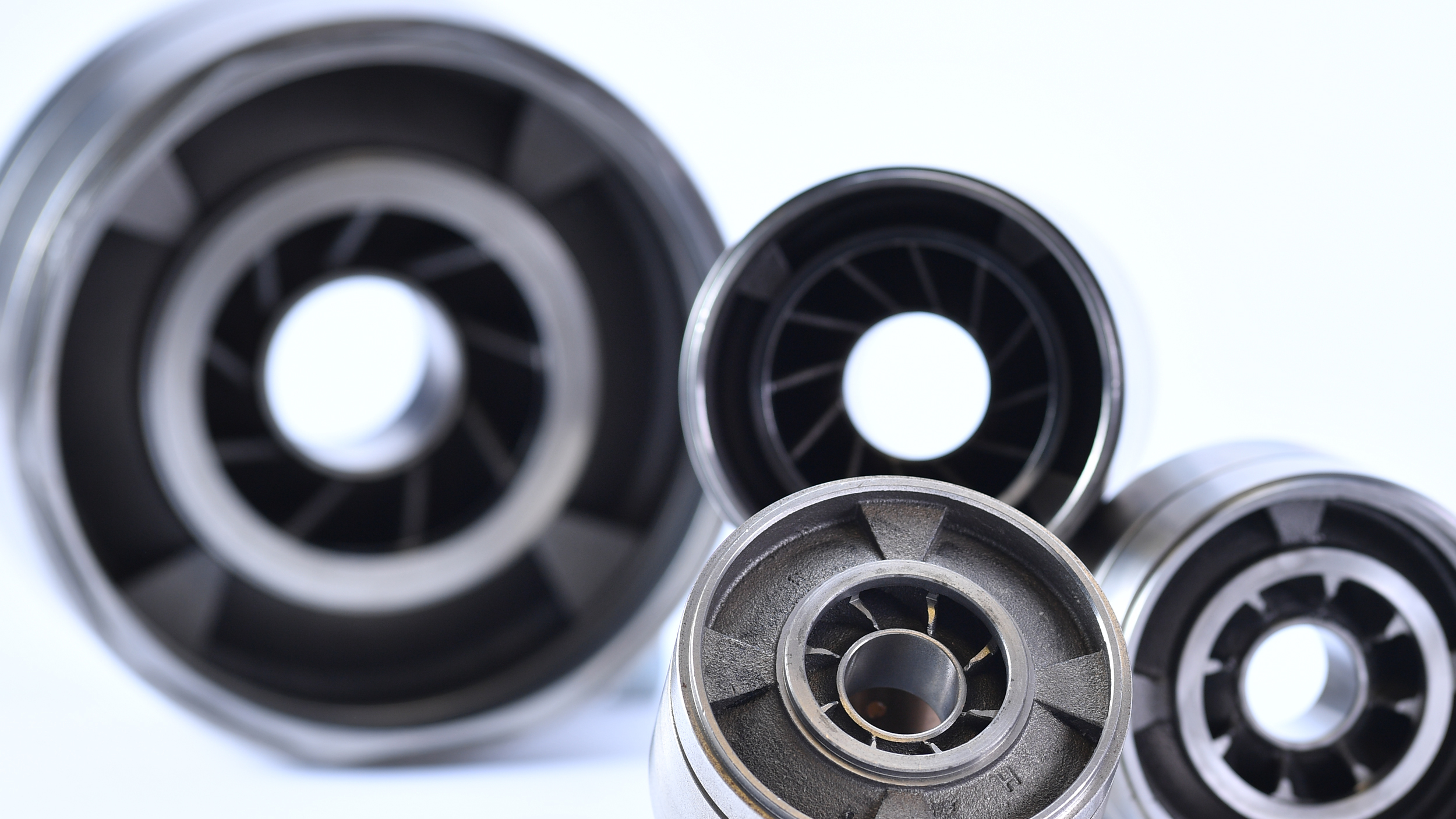

Side-by-side comparison with standard pump diffusers

Download PDFMature Fields

Decrease diffuser and pump housing erosion to increase pump run life

Alaska

In a well operated in Alaska, pump stages using standard diffusers showed significant housing erosion when the electric submersible pump (ESP) system was pulled. The erosion was caused by abrasives, made worse by high flow rate, making the pump run life average about one year in these conditions.

Diffusers with the Erosion Buster® design were added to critical stages of the Tiger Shark® pump to deliver extended run life. After a year of service the pump was pulled. Upon examination, Summit ESP found that where the diffusers with the Erosion Buster design was in place, the pump housing was intact and there was only minor erosion in the diffusers. In the standard diffusers, abrasives had eroded through the housing in three locations.

In contrast to the standard ESP diffuser design, the unique Erosion Buster design redirects fluid path inward and into the primary flow path, decreasing wear on critical areas. In addition, the diffuser includes a heavier wall construction, increasing durability and run life. The Erosion Buster technology has emerged as the industry leader, further extending run life in abrasive applications, and making the run life for this new configuration nearly double.

pump housing erosion

increase in run life

Tiger Shark® electric submersible pumps are designed to adapt to changing well production, improving operating range and run life in harsh environments.

Halliburton's Summit ESP® electric submersible pump systems increase run life and maximize production.