Search

Search

Search

Search

Provides active magnetic ranging to accurately determine the position of nearby wellbores and reduce survey errors

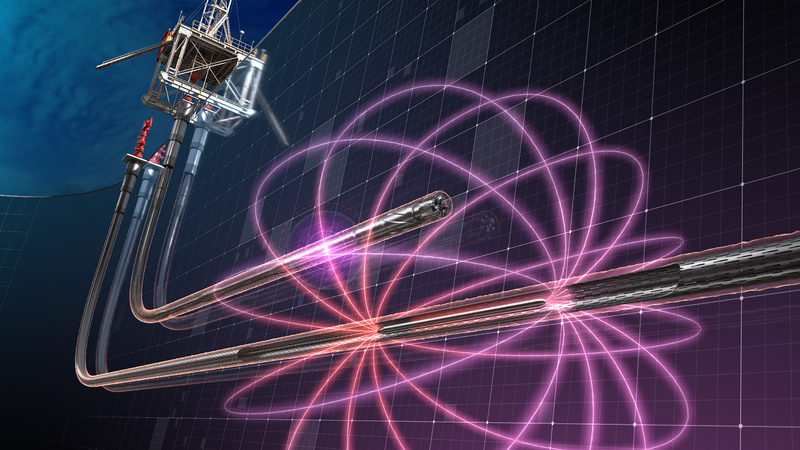

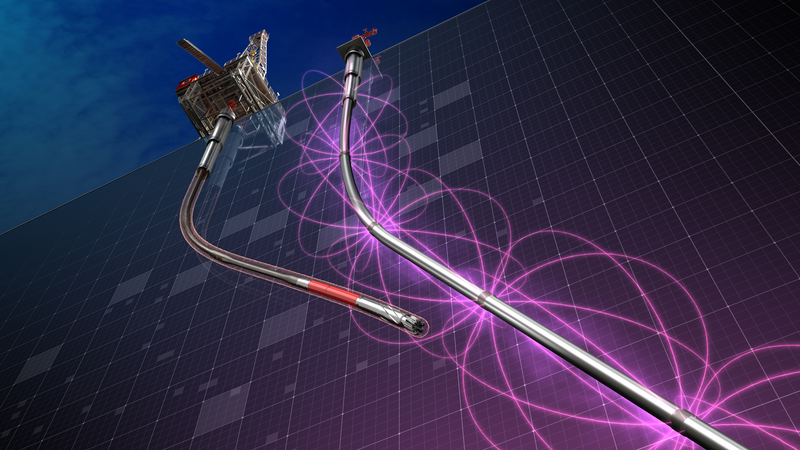

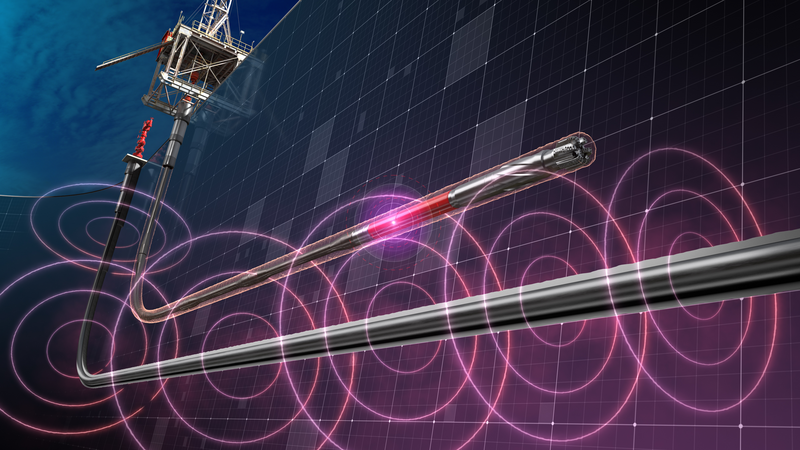

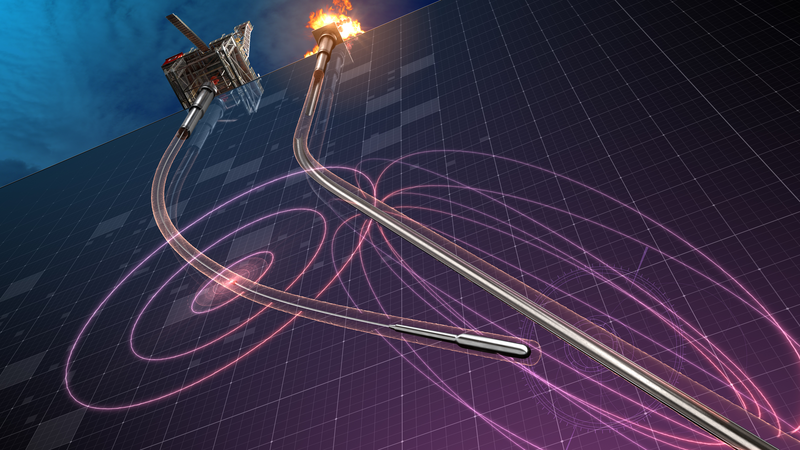

Talk to an expertOperators need a reliable way to know the relative placement between two or more wells with a larger separation distance to safely drill in the same area. The RMRS™ rotary magnet ranging system provides active magnetic ranging to accurately determine the position of nearby wellbores and reduce survey errors.

The RMRS system operates with well-to-well separation distances up to 262 ft (80 m). From the reference or target wellbore, the RMRS sensors detect the magnetic field generated by magnets embedded in the specially equipped extended-gauge bit or bit sub in the drilling or pursuit well.

Halliburton has deployed the RMRS rotary magnet ranging system in more than 1,000 wells globally.

Magnetic ranging solutions demonstrate a well-established history of expertise, proving our dedication to precision when navigating the intricacies of well proximity applications

The MGT™ magnetic guidance tool is an active magnetic ranging solution that allows parallel wells to be drilled within highly accurate separation tolerances.

The Passive Magnetic Ranging (PMR) service utilizes the remnant magnetic fields on target well tubulars to provide a distance and direction between wellbores.

The Aurora™ surface-access magnetic ranging service provides accurate well placement in SAGD applications without downhole intervention.

WellSpot™ active magnetic-ranging systems use precise sensors to provide data for multiple drilling applications.