Search

Search

Search

Search

Locates wells with accuracy and precision

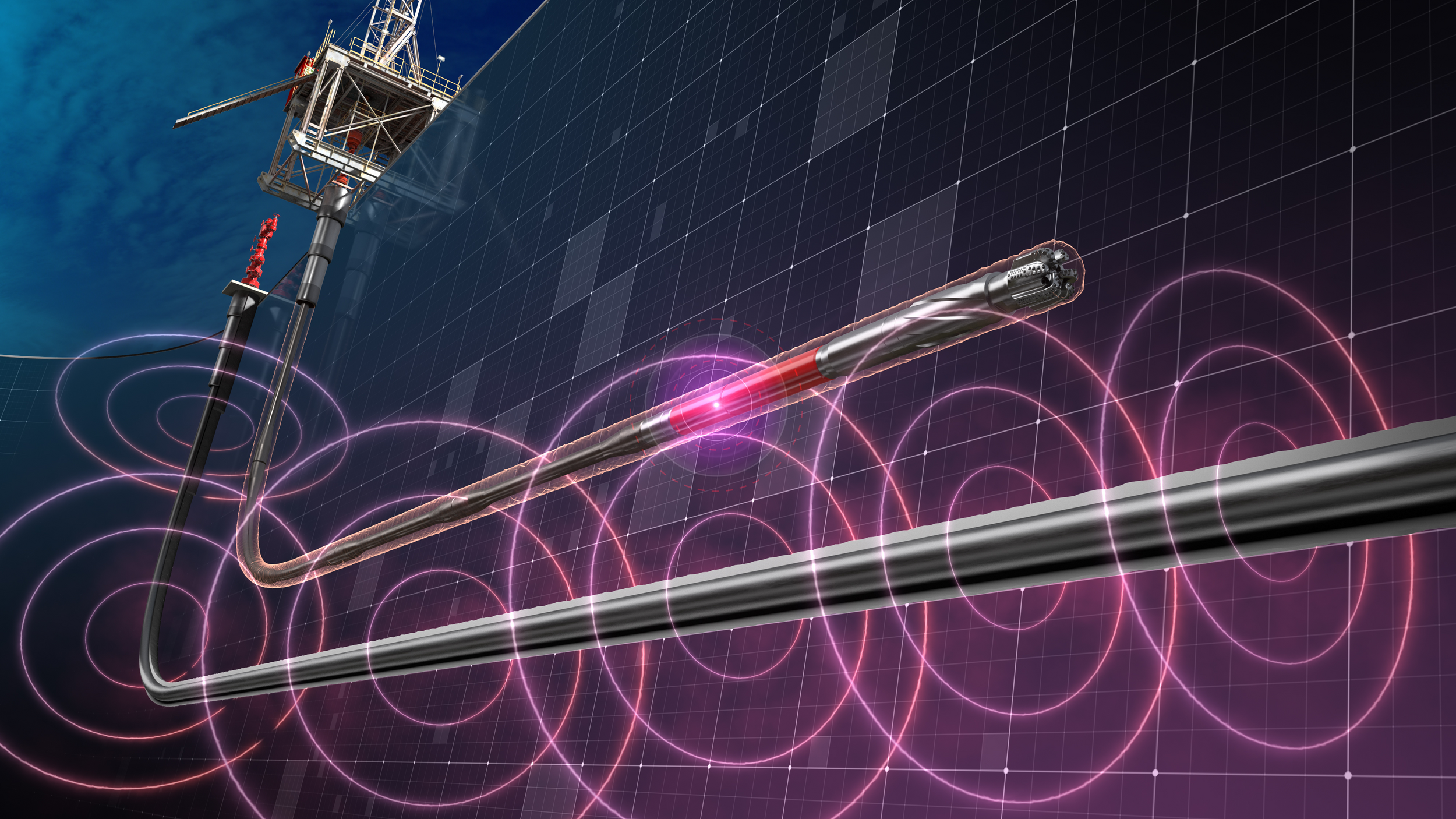

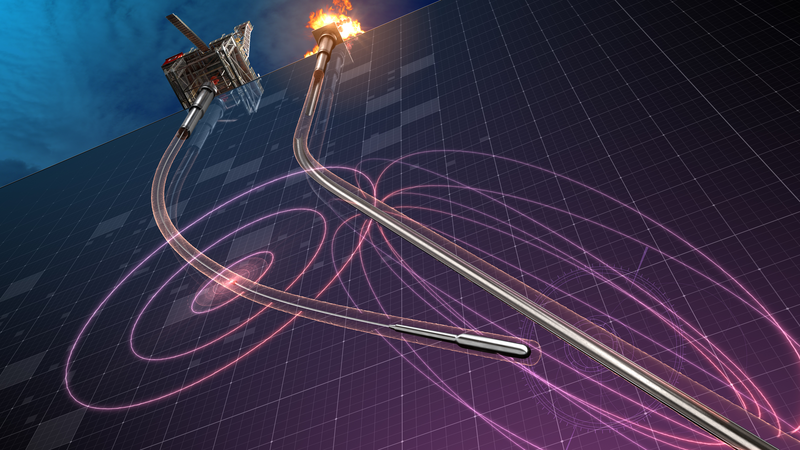

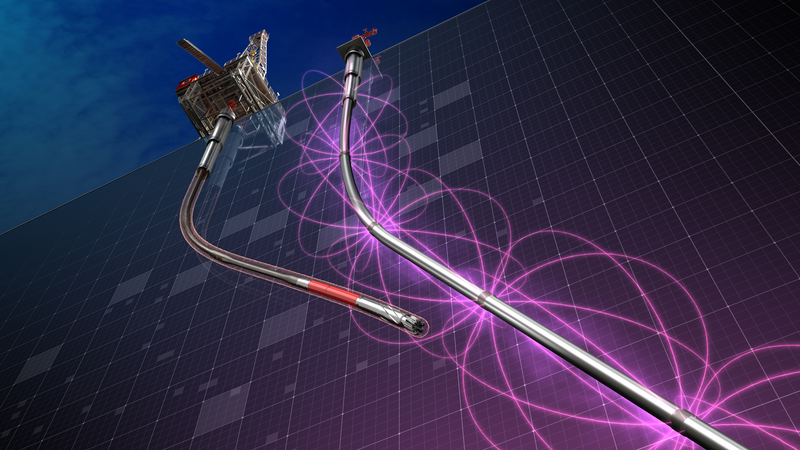

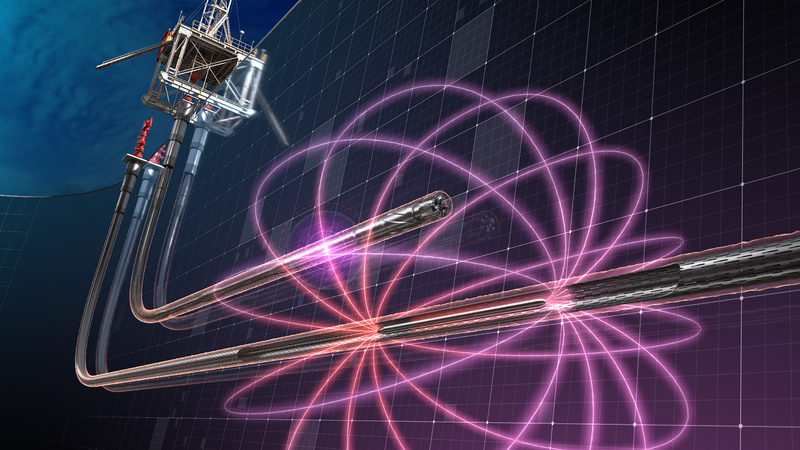

Talk to an expertOperators producing heavy crude oil and bitumen require in-situ thermal recovery techniques such as steam-assisted gravity drainage (SAGD) development to recover hydrocarbons. The Aurora™ surface-access magnetic ranging service is designed for SAGD applications where parallel stacked horizontal wells require to be drilled into the reservoir just a few meters apart with a high degree of accuracy. The service uses surface excitation to determine a ranging distance and direction relative to the drilling wellbore.

The Aurora service helps operators overcome challenges, including high infrastructure and operational costs, large pad design and wide slot spacing, uncertain well placement, conveyance challenges and removal of wireline conveyed tools that have temperature limitations.

An industry first, the Aurora service connects to the target wellbore via the wellhead. The surface access allows operators to eliminate the need for wireline ranging conveyance. Streamlining the ranging process helps reduce rig time, operation costs, and health, safety, and environmental (HSE) risks.

Magnetic ranging solutions demonstrate a well-established history of expertise, proving our dedication to precision when navigating the intricacies of well proximity applications

WellSpot™ active magnetic-ranging systems use precise sensors to provide data for multiple drilling applications.

The Passive Magnetic Ranging (PMR) service utilizes the remnant magnetic fields on target well tubulars to provide a distance and direction between wellbores.

The RMRS™ rotary magnet ranging system provides active magnetic ranging to accurately determine the position of nearby wellbores and reduce survey errors.

The MGT™ magnetic guidance tool is an active magnetic ranging solution that allows parallel wells to be drilled within highly accurate separation tolerances.