Search

Search

Search

Search

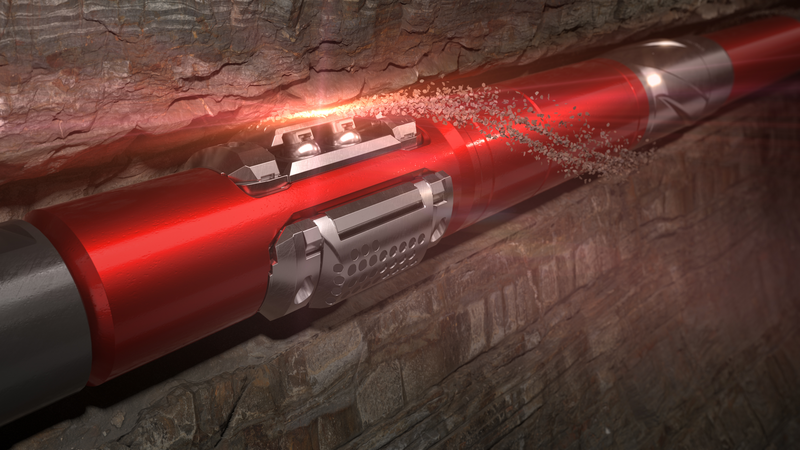

Our directional drilling systems are engineered to reduce well time and maximize reservoir contact from unconventional to extended-reach environments

Talk to an ExpertHalliburton Sperry Drilling provides performance-driven services, solutions, and advanced products that include rotary steerable systems (RSS), drilling mud motors, turbodrill turbines, and downhole tools.

Our drilling experts plan, design, and model high-angle and complex well trajectories utilizing our DrillingXpert® software to help increase drilling performance and reduce costs.

During real-time operations, our autonomous drilling platform helps directional drillers make quicker, smarter decisions to stay on plan and achieve predictable results consistently.

WORLD OIL / OCTOBER 2018

Advancements in electronics and sensor technology, sophisticated algorithms, and high-speed telemetry are leading the way to automated drilling.

SEE FULL ARTICLE

Halliburton rotary steerable systems are engineered with advanced technologies to reduce well time and accurately place well in reservoir.

Explore

Halliburton drilling motors ensure faster drilling, reduced well time, and more accurate well placement in any basin application.

Explore

Provides the power and performance to consistently deliver faster and longer runs.

With Turbopower™ turbodrills, Halliburton can engineer a solution to meet any operational challenge.

Explore

Halliburton has the expertise and downhole technology to ensure accurate well positioning at a precise location.

Explore