Search

Search

Search

Search

Halliburton's Summit ESP® electric submersible pump systems effectively increase run life and maximize production

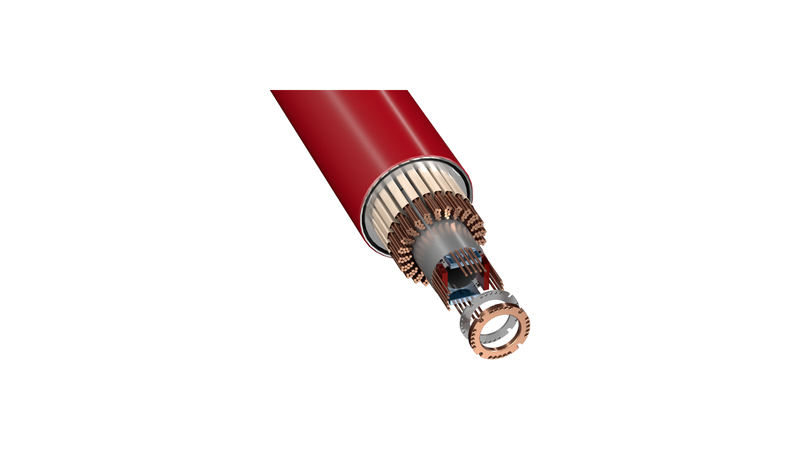

Talk to an ExpertWe deploy Halliburton ESP systems in the most extreme downhole environments. High temperature, immense pressure, fluid-borne abrasives, excessive gas, scale, and variable flow rates are common. Innovative technologies in our ESP systems directly address each threat. Our technology, superior service, and expertise widen the performance gap to our closest competitors.

Request Product CatalogResearch and Development

Explore R&DWe are developing innovative products and platforms with robust engineering, insightful data analysis, and superior reliability for the harshest applications in artificial lift.

A cloud-based application for designing and assessing electric submersible pump performance with online and offline capabilities streamlining and integrating several data sources, transforming trust-worthy insights into long-term ESP success.

explore spyglass

TrueSync hybrid permanent magnet motor offers efficiency, sustainability, and reliability.

The Hydro-Helical® gas separator sets a new industry standard for flow rate, performance, and reliability.

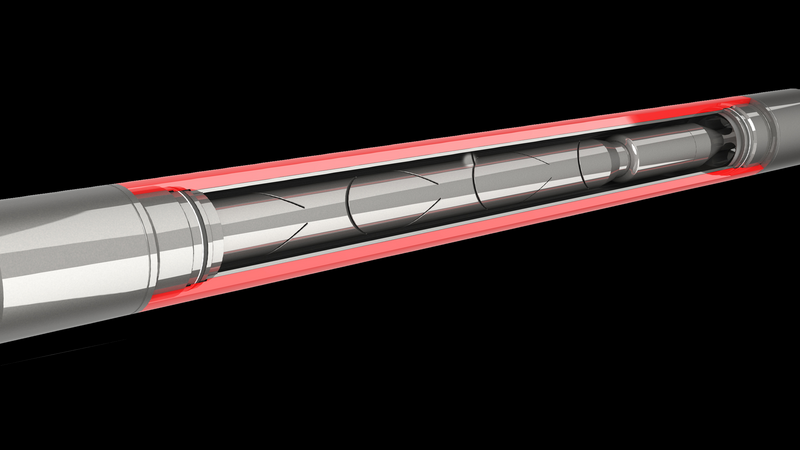

Innovative design with liquid reservoirs to help mitigate gas slugs in conventional, unconventional, and SAGD wells for enhanced performance and reliability.

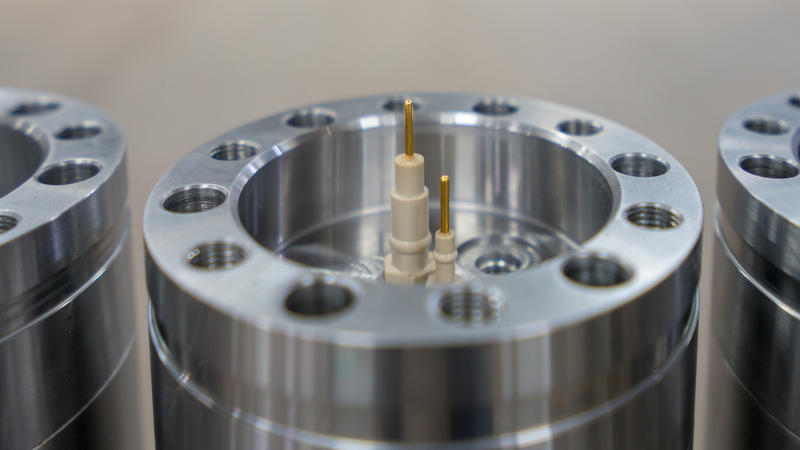

Triton gauges from Summit ESP® are the next generation of downhole gauges with leading-edge technology that provide superior asset surveillance.

The SandRight® tool prevents solids from entering the ESP system during shutdown events, eliminating overstressed motors and accelerated pump wear when restarting the system.

Tiger Shark® electric submersible pumps are designed to adapt to changing well production, improving operating range and run life in harsh environments.