Search

Search

Search

Search

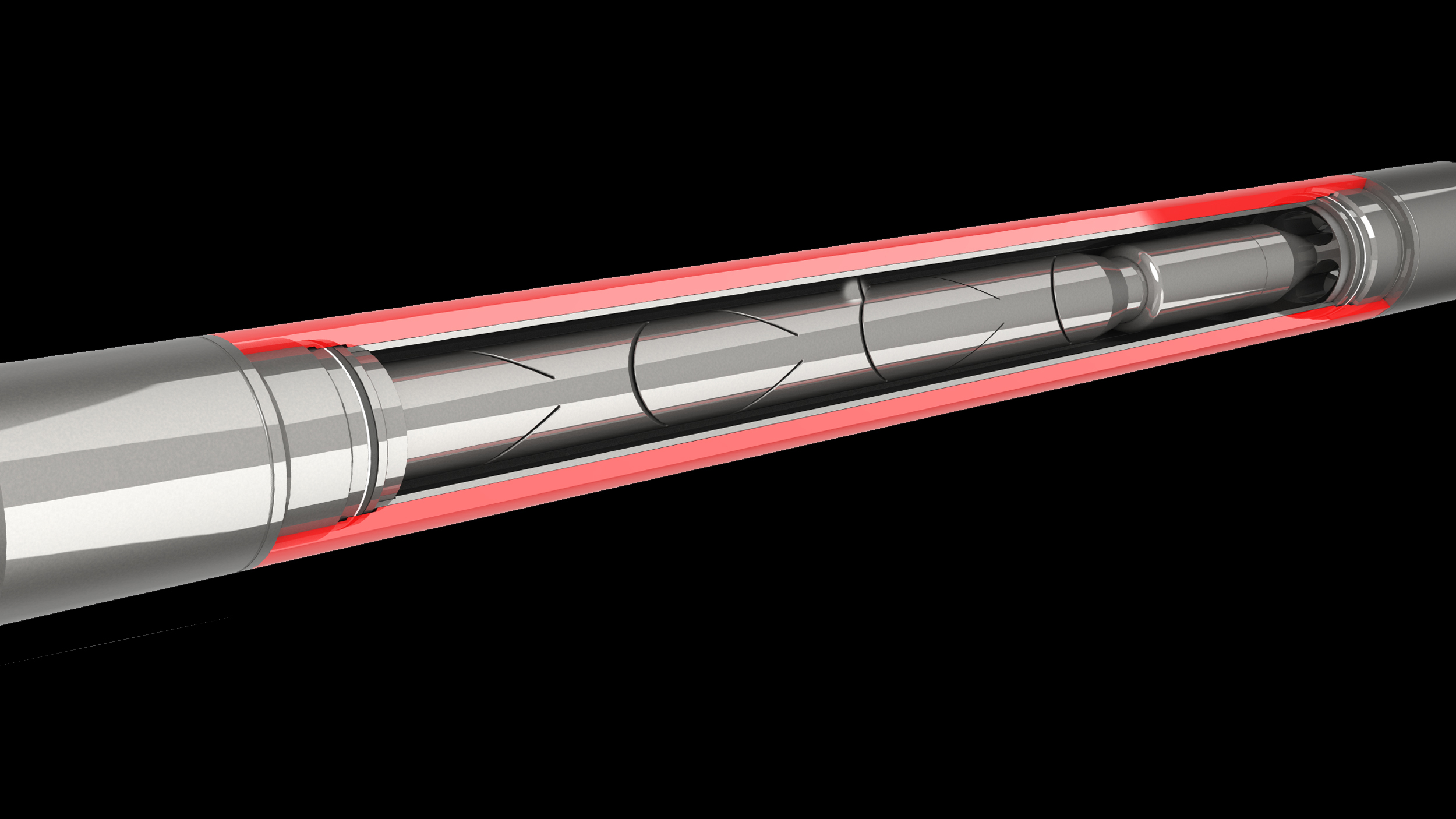

The unique design deters damaging solids and sand from entering the electric submersible pump during power shutdown events.

talk to an expertUnlike other solutions in the market, SandRight maintains the ability to execute through-tubing chemical treatments while also resisting paraffin and scale buildup by using superior materials. The tool was specially designed to be easy to install, reliable, compact, and seamlessly integrated into our ESP production system.

In addition to preventing sand from flowing in reverse direction when the well shuts down, the SandRight tool provides higher abrasion resistance for longer wear and resists paraffin/scale buildup.

Derived from Halliburton’s expertise in fluid sand transport, the SandRight tool prevents catastrophic damage during shutdown.

02:49

Solids lodged in the pump stages during shutdown events stress the pump. The SandRight Solids Fallback Preventer deters damaging solids from entering the electric submersible pump (ESP) during these events. Its unique design features preserve the ESP, especially in wells subject to dislodged formation and frac sands. The tool similarly maintains the ability to execute through-tubing chemical treatments while also resisting paraffin/scale buildup by using superior materials.

Case Study: Oklahoma

SandRight® solids fallback preventer and Hydro-Helical® gas separator combined with the Intelevate™ platform further to optimize production.

See case studyCASE STUDY: MIDDLE EAST

Operating expenses and deferred production were reduced in three wells.

READ CASE STUDYWhen an ESP is shut down, solids hovering in the production tubing above the ESP are a major issue, especially in unconventional applications. These solids fall back to the pumps and become lodged in the pumps’ stages. Restart attempts can overstress motors, accelerate pump wear, overheat the cable, and/or result in catastrophic failure.

The SandRight tool not only protects the pumps from permanent damage due to solids fallback but also significantly increases an ESP’s runtime in unconventional applications.