Search

Search

Search

Search

The tailored pump design delivered 600+ days of production at low flow rates

Download PDFUnconventional

Maintain efficient operation with an ESP as production declines

Oklahoma

Maintain efficient operation with an ESP as production declines to less than 200 BTFPD while dealing with excessive gas

Custom-designed pump system optimized for low-flow conditions

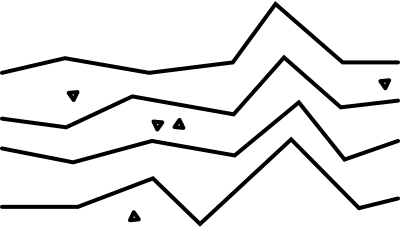

Historically, electric submersible pump (ESP) systems were considered impractical for wells with production rates below 300 barrels of total fluid per day (BTFPD) due to the maintenance expenses needed to keep ESPs operational. When production declines to this level, the industry typically switches to alternative artificial lift methods like rod pumps or gas lift. Although these alternative methods favor lower operating costs in the “low flow” market, conversion expenses can soar to over $150,000, including labor and other third-party costs.

As unconventional drilling becomes more prevalent, the effectiveness of rod lift systems has diminished due to tubing wear caused by navigating harsh doglegs and tubing leaks near the bottom of the well. When an Oklahoma customer had a well decline to less than 200 BTFPD, 400 psi BHI, they decided to try a new approach using a low-flow ESP design.

Halliburton designed a system optimized for low-flow conditions:

The installed design delivered 600+ days of production at low flow rates. When the equipment was finally pulled, a new system of the same design was immediately ready. Staying with electric submersible pump (ESP) production saved the operator over $150,000 in conversion costs while maintaining the same enhanced benefits of producing with an ESP. Within a month, the new equipment delivered the same outstanding performance as its predecessor at a rate of 100 BTFPD.

Tiger Shark® electric submersible pumps are designed to adapt to changing well production, improving operating range and run life in harsh environments.