Search

Search

Search

Search

LOGIX® automation and remote operations, iCruise® RSS, and DrillingXpert™ software deliver flawlessly in MPD underbalanced drilling environment.

Download PDFMature Fields

Drill and geosteer in MPD environment with up to 7% N₂ injection rate

Colombia

Variables for successful horizontal well drilling include hole cleaning, efficient trips, adjusting planned trajectory, achieving a smooth trajectory to control tortuosity, and others. When performing MPD underbalanced drilling with directional tools, these variables further impact execution results.

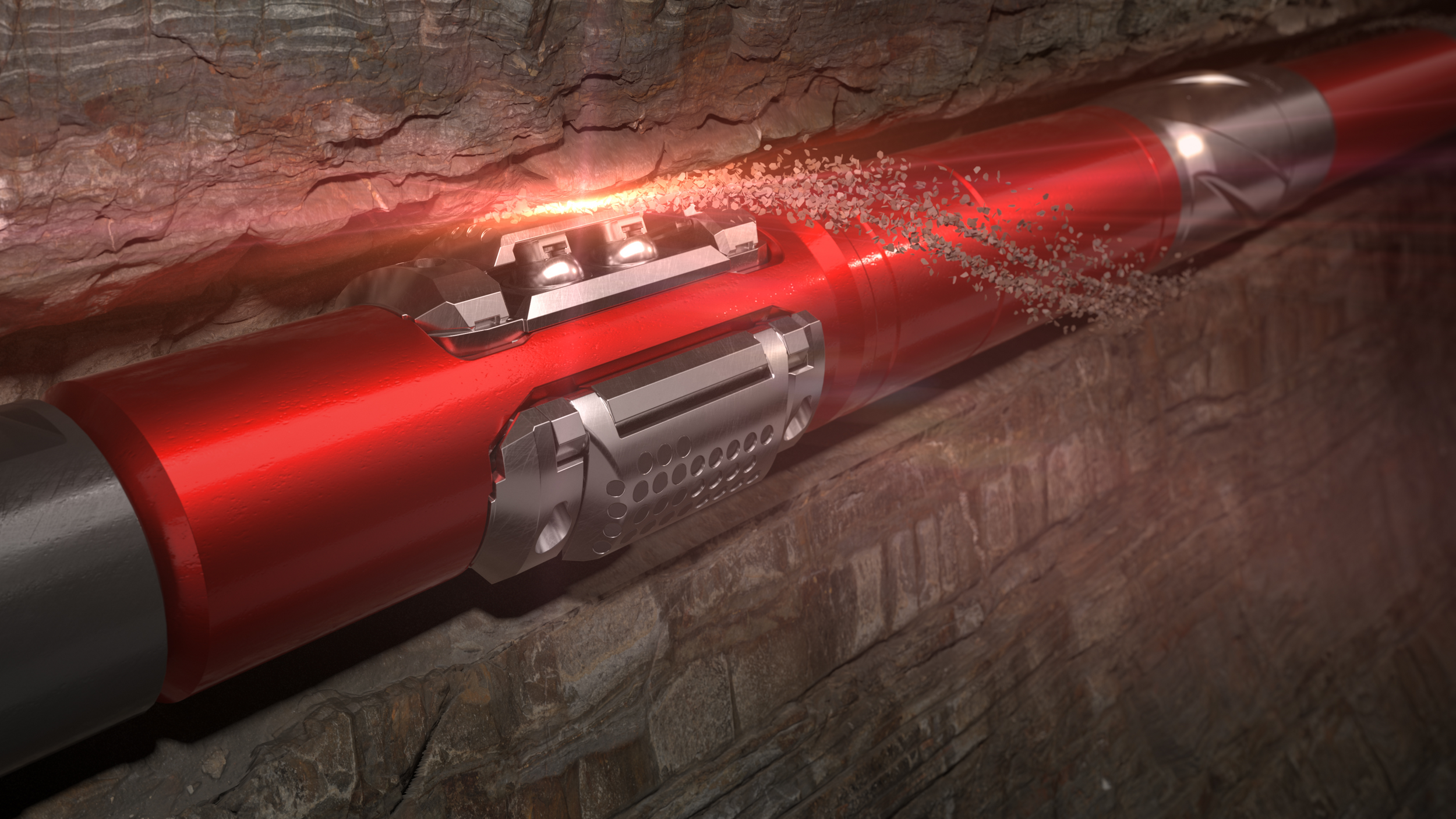

An operator required drilling in an underbalanced environment with N₂ injection using a rotary steerable system (RSS) without losing directional control. In this intriguing MDP drilling environment, another challenge was maintaining data transmission using positive pulse telemetry while drilling with a biphasic fluid, which decreases mud density and can cause signal strength to weaken or become lost. Additionally, like geosteering operations, the operator wanted the capability to change trajectory with a good balance between changes and tortuosity.

N₂ Injection Rate

Shoe-to-shoe run

ft.

Drilling in an MPD environment with N₂ injection required a detailed pre-job planning and design process, particularly considering the effect of pumping nitrogen on the functionality and configuration of the iCruise® RSS. A global support team conducted several advisory sessions to determine the optimum configuration. All engineering was developed using the DrillingXpert™ software to determine the best hydraulic configuration and BHA stabilization to aid trajectory, obtain optimum LWD quality data control, and minimize vibration. A remote drilling center worked directly with field engineers to support drilling performance optimization and vibration mitigation in real time.

This was the first iCruise RSS run globally in an underbalanced environment. Collaborative engineering efforts delivered a 2,442 ft, 85° inclination section in a single run where nitrogen pumped reached up to 7%. The operator required geosteering in limestone and had to adjust the trajectory several times with extreme caution to maintain a low dogleg and deliver a smooth borehole. The section was steered successfully without losing steering capacity. With this case study, the Halliburton team illustrates how collaborative efforts and innovative solutions can deliver engineering solutions to maximize the operator’s asset value.