Search

Search

Search

Search

iCruise® intelligent rotary steerable system lands 3D curves on target, stays 100% in zone

Download PDFUnconventionals

Deliver an engineered drilling solution using an intelligent RSS

Marcellus Shale, Butler County, PA

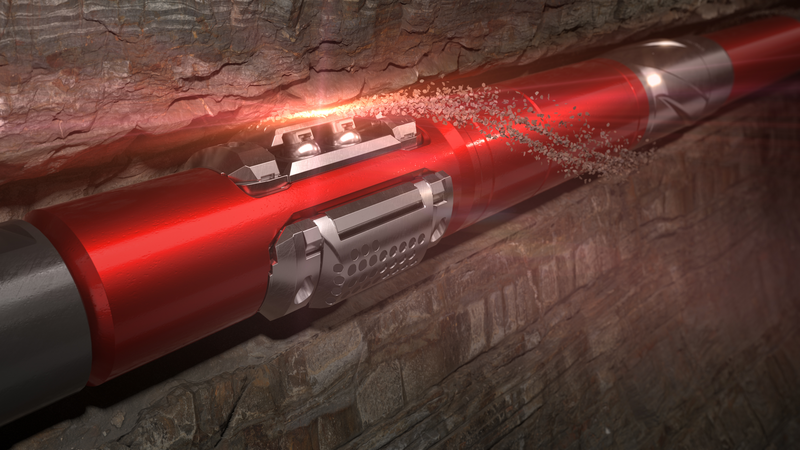

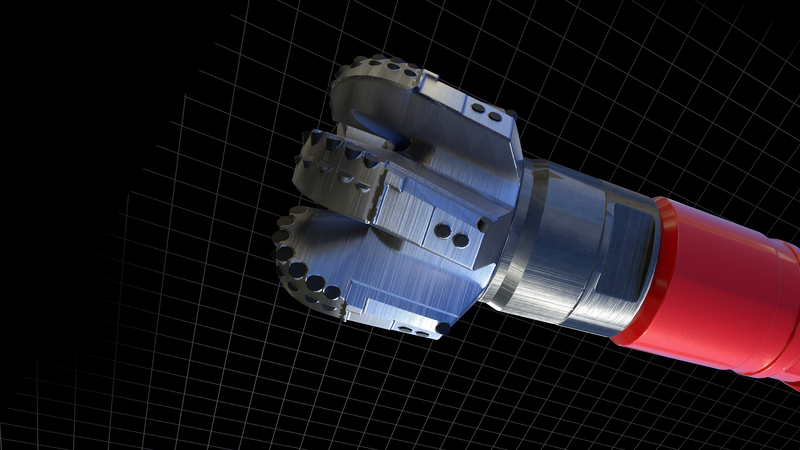

An operator drilling in the Appalachian Basin required to maximize reservoir contact and drilling efficiency. Drilling Engineering Solution (DES) experts from Halliburton Sperry Drilling listened to the technical challenges and collaborated with operator and delivered an engineered drilling solution utilizing iCruise® intelligent rotary steerable system with a 8-1/2- inch GeoTech® GTi54 drill bit. The solution resulted in successfully drilling three 3D curve profile and lateral to total depth in a single run each time.

The three wells were drilled with zero HSE incident, landing the 3D curves on target and staying 100% within the preferred target. The activation of CruiseControl™ technology allowed a specific inclination and azimuth to be maintained, delivering a smooth and high quality wellbore with minimal tortuosity.

The assembly delivered an outstanding performance maintaining a high rate of penetration. The performance was a significant improvement in drilling efficiency and maximized the value of the asset.

Run to Reach Total Depth (TD)

Health, Safety, and Environmental (HSE) Issues

in the Target Zone

Halliburton rotary steerable systems are engineered with advanced technologies to reduce well time and accurately place well in reservoir.

Reduce well time through fast drilling, fast tripping time and quicker casing drill outs.

GeoTech® matrix and steel body drill bits are customized to deliver performance across all drilling applications.