Search

Search

Search

Search

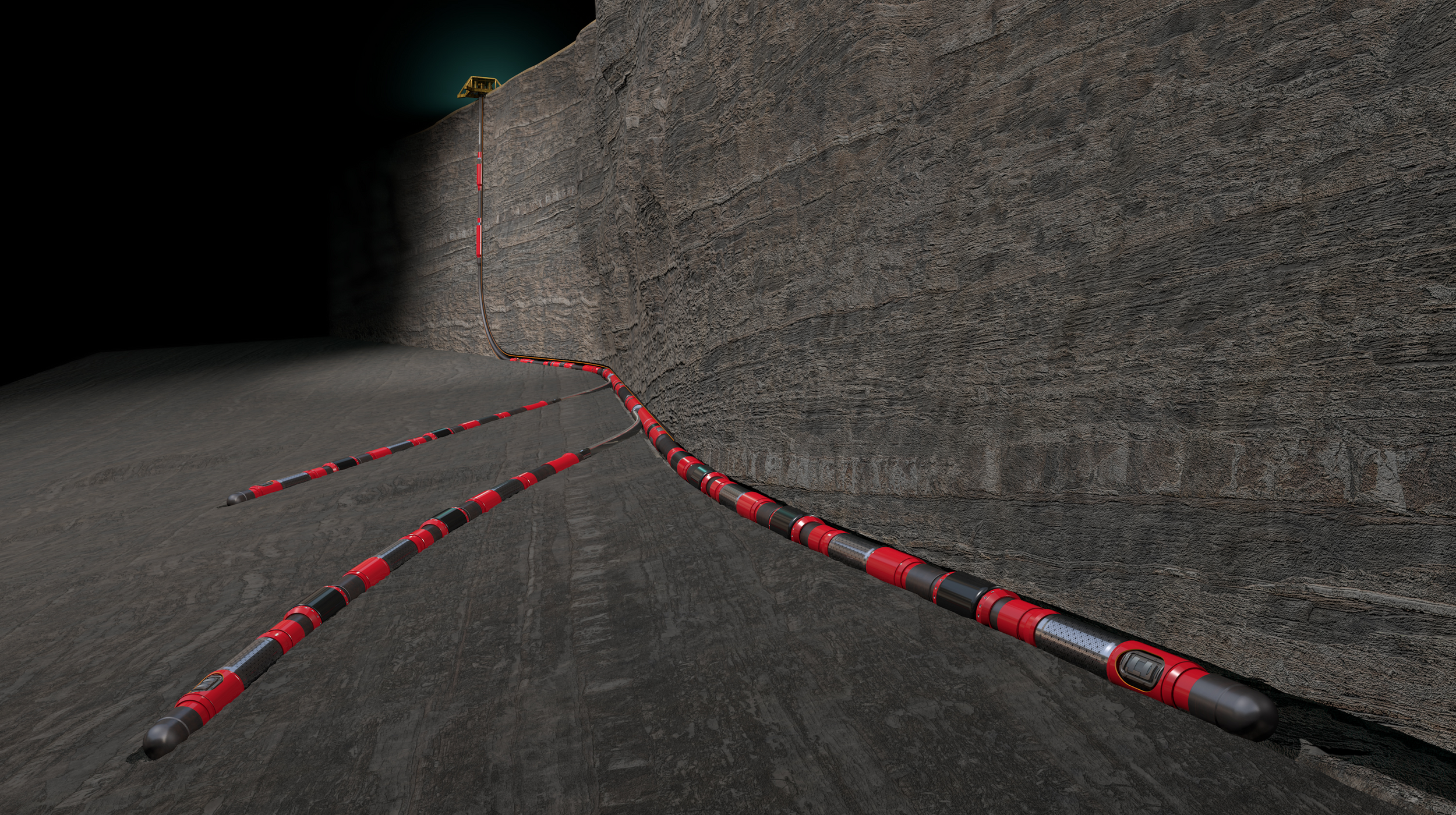

Multilateral technology has evolved to continuously meet challenges facing operators in the Middle East for more than two decades.

Download PDFMature Fields

Increasingly complex reservoir and production requirements

Middle East

For a quarter of a century, Halliburton’s sustained technological advances in multilateral technology have enhanced economics and extended the production life of fields in the Middle East. Multilateral applications in the region have evolved from standard Level 2 and Level 4 dual-laterals to dual-laterals with intelligent flow control, intervention capabilities, and improved junction integrity

Early multilateral wells were drilled onshore as Level 2 uncemented dual-laterals that exited out of 9 5/8 inch casings with openhole laterals and no liners or completion equipment. These wells had limited options for intervention and production isolation between the mainbore and laterals. By the mid-1990s, operators began installing multilateral wells offshore in addition to onshore, and more laterals were being completed as Level 4 dual-laterals with cemented junctions and lateral liners. Placing cement around the junction helped prevent sand infiltration and the potential for collapse as well as providing a full inner diameter of the casing and the foundation to allow selective through-tubing intervention in both a mainbore and lateral. By the late 1990s, the first tri-lateral well had been installed in the region.

The IsoRite® multilateral intervention system, first installed in the Middle East in 1997, addressed the need to complete through-completion intervention operations on both new and existing wells. The intervention system had to be compatible with the Level 4 cemented multilateral junctions being installed in the region and with coiled tubing, wireline, and slickline as intervention methods. To date, multilateral intervention systems have primarily been used to enable intervention access to Level 4 cemented junctions. Now, however, this system is beginning to provide the same value and versatility to Level 2 noncemented junctions as well.

The FloRite® pressure-isolated Level 5 system, first installed in the Middle East in 1998, allows the system to be installed on constructed Level 4 or Level 2 junctions, adding pressure isolation. The system can be configured for dual-string segregated flow, commingled flow, or intelligent completions integration. Pressure isolation is maintained using a dual-bore deflector at the junction as well as upper and lower mainbore packers and a lateral packer.

The first installation needed pressure isolation and junction integrity provided by a cemented junction; the top of the reservoir was fractured and needed to be isolated; losses and water flow above the reservoir needed to be isolated; and two target zones needed pressure isolation to be produced effectively. In conjunction with the Level 4 cemented junction, the multilateral pressure-isolated Level 5 system allowed the operator to achieve well objectives and produce both targets through segregated dual-completion to surface.

1st lateral re-entry installed

years of multilateral technology in Middle East

successful multilateral wells constructed

Throughout the last 25 years, more than 400 multilateral wells have been successfully constructed in the Middle East region. Thanks to equipment modifications and operational improvements in multilateral technology and drilling methods, the time needed to install each well has been dramatically reduced. Nonproductive time events have also decreased because the operator has standardized multilateral systems and collaborated on continuous technology and procedural improvements.

Today, multilateral well designs can be adapted to most reservoir management and production applications. Multilateral technology has been able to keep pace with the complexity of well requirements, and multilateral technology advancements have enabled reliable and efficient multilateral operations by introducing intervention capabilities, flow control, and monitoring. Applying these innovative technologies provide a greater variety of options to meet the completion, workover, and intervention requirements of multilateral wells.

Greater profitability and a higher return on investment with innovative multilateral technology