Search

Search

Search

Search

Cemented Datasphere® Array system gauges + Clariti® View services provide all-inclusive data acquisition, storage and alerting

Download PDFCost-effective permanent monitoring system to monitor CO2 containment zones.

North Dakota

Cost-effective permanent monitoring system to monitor CO2 containment zones.

DataSphere® Array permanent monitoring system and Clariti® View visualization services.

Real-time reservoir pressure and temperature monitoring, with quick access to data insights.

A carbon capture utilization and storage (CCUS) operator in the Bakken needed an effective method to monitor formation pressures and temperatures from previously identified “containment zones” in which carbon dioxide (CO2), the byproduct of ethanol production facilities, would be injected. In addition, the operator’s plans had to abide by the local regulatory standards set to help reduce the amount of CO2 released into the atmosphere and its potential effects on climate change.

Monitoring standards set by local government entities present significant challenges for CCUS operators. During the CO2 injection phase, the operator must provide proof that their injection pressures are well below the formation frac pressures, mainly to avoid any potential channeling or fracturing into nearby formations or water tables. Following CO2 injection, the integrity of such containment zones must be monitored for a mandated amount of time. In this case, the operator had to monitor the containment zone for a minimum of 10 years; however, regulatory entities in other areas might require monitoring for up to 100 years.

Currently established solutions for formation pressure monitoring use perforating systems, along with permanent monitoring gauges, which can be cumbersome, costly and slow to deploy. Such systems utilize multiple connections (potential failure points) and perforating charges that pose health, safety and environment (HSE) risks, ultimately leading this CCUS operator to explore alternative solutions in the market.

Regulatory standards required that the operator provide CO2 injection data to ensure the integrity of the targeted containment zone. The operator wanted a cost-effective CCUS monitoring solution that would increase the speed of operations, reduce complexity and ultimately provide accurate reservoir pressure and temperature measurements, all while providing remote data access, data storage and alerting in the event of a leak.

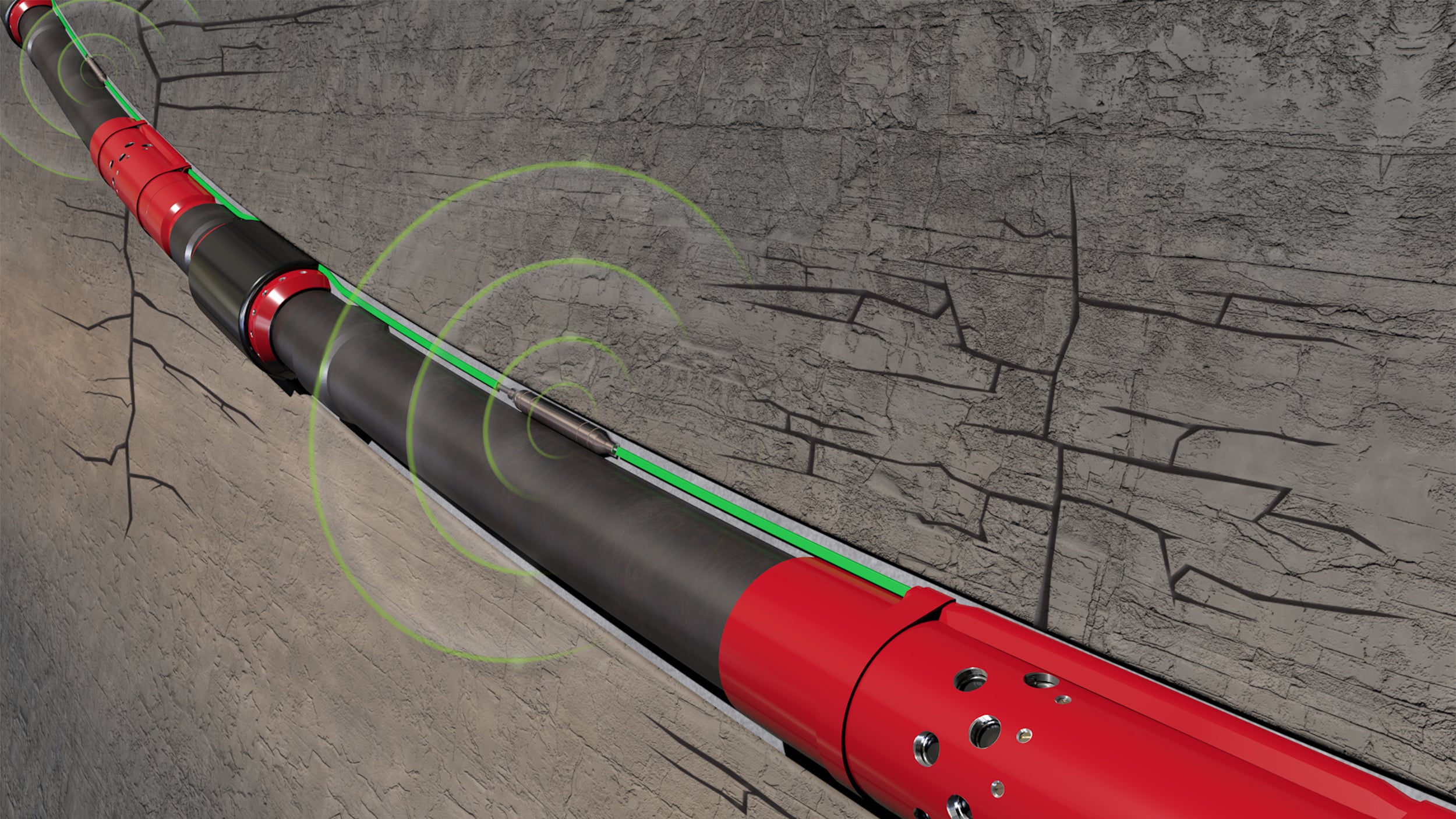

Halliburton proposed a cemented, casing-deployed DataSphere® Array permanent monitoring system for long-term monitoring of the containment zone, in conjunction with Clariti View reservoir management services for alerting, ease of data visualization and access for accurate reporting.

connections & mandrels with the DataSphere Array System

CO2 containment zone monitoring

reservoir pressure and temperature monitoring

The integrated services provided a cost-effective, reliable and efficient solution for long-term CCUS monitoring that met the operator’s objectives and maximized asset value.

Using the cemented DataSphere Array system helped the operator decrease deployment time because the system has no connections, no mandrels and simply clamps to the casing along with fiber-optic cable. In addition, the ability to measure formation pressures and temperatures through cement eliminated the need, and associated costs and HSE risks, for perforating charges.

Clariti View provided a seamless solution to access array sensor data remotely from any device, without the operator having to install or maintain the infrastructure necessary. The monitoring platform stores data in a secure cloud and provides access via the Clariti View visualization dashboard, where the operator can view live data, download historic data and set alert triggers to stay ahead of any remediation needs. This also helps ensure the operator meets regulatory agency reporting requirements with up-to-date information.

The DataSphere permanent monitoring suite is a robust combination of the best in sand control, multilateral, and intelligent completion technology

Clariti View is an integrated service that provides real-time downhole gauge pressure and temperature information