Search

Search

Search

Search

Solution optimizes drilling time by 14.75 days

Download PDFMature Fields

Perform drilling campaign to maintain production

Napo Basin

A client in Ecuador turned to Halliburton to perform its 2016–2017 drilling campaign in order to maintain production in the Napo Basin.

The objective was to safely and effectively deliver a production well in the main pay reservoir, within the specified budget and with effective hydraulic isolation. The project scope included basic integrated services with a coordinator managing all activity in the one field.

Halliburton was challenged to design, drill, and deliver wells in the Napo Basin – and to do this safely, efficiently, on time, and within the allocated budget. The geology in the field presented significant obstacles, including drilling through highly reactive shale sequences with borehole instability issues and depleted formations at critical points within the well geometry. These conditions, which tend to slow drilling with associated problems and to historically increase the total well time, required proper engineering.

To reduce drilling time and well costs, the Halliburton Project Management (HPM) team developed plans and procedures from lessons learned on previous campaigns that would overcome the anticipated downhole issues. Halliburton Project Management created a synergy between all groups involved in the well construction, including all Halliburton product service lines (PSLs) and third parties. This included:

Highlights/New Technology

Ft horizontal displacement (fastest directional well)

Total days saved, including completion

USD saved for the customer

Well Non-productive time (NPT)

Through proper planning and efficient execution, Halliburton Project Management safely delivered a J-shaped high-angle well 14.75 days ahead of the planned time to ultimately save the customer approximately USD 3.5 million. The plan was based on best practices and field experience gained by all the Halliburton product service lines involved in the well construction. Effective pre-planning in advance of drilling the well played a major role in having a smooth, seamless operation. This outstanding performance was a result of strong integrated services leadership, effective collaboration between the parties, and processes and execution with the right Halliburton technology application and operational support.

The well was delivered significantly ahead of the original plan, while still meeting all of the following client objectives:

Halliburton drives efficiency and maximizes asset value through collaborative engineering, resource integration, and risk management.

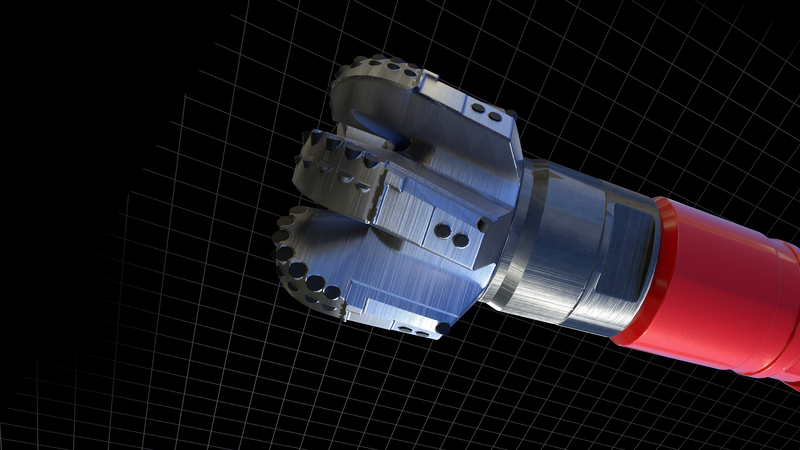

GeoTech® matrix and steel body drill bits are customized to deliver performance across all drilling applications.

The Halliburton Geo-Pilot® rotary steerable systems (RSS) is designed to deliver unprecedented speed and precise steering.

Field-proven, total system approach to liner installations

Halliburton delivers superior drilling performance to reduce time to first oil, enhance reservoir knowledge, and maximize production.