Search

Search

Search

Search

Field-proven, total system approach to liner installations

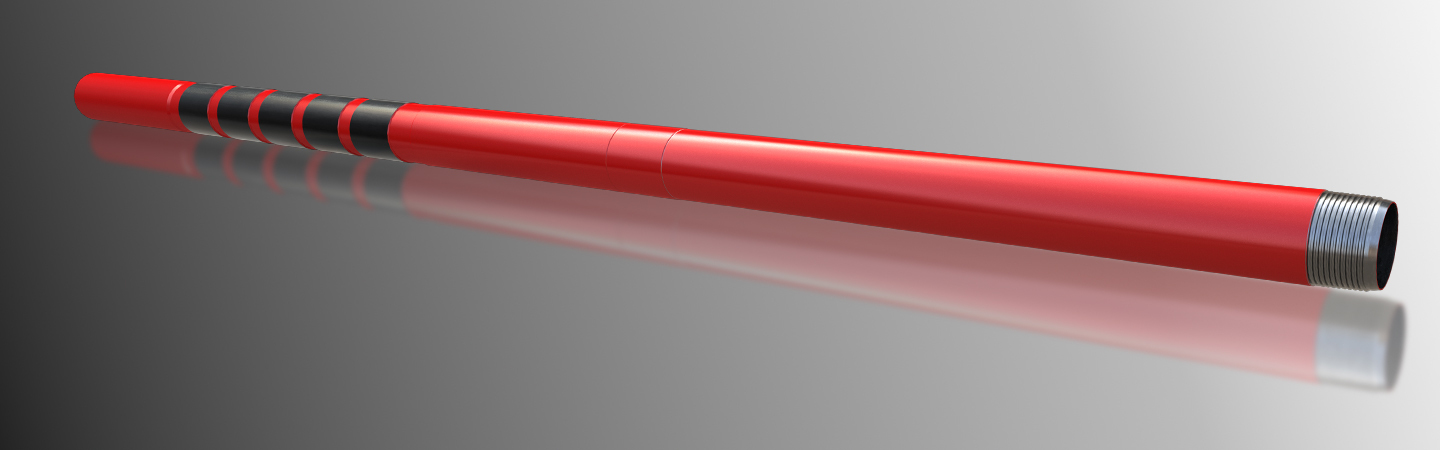

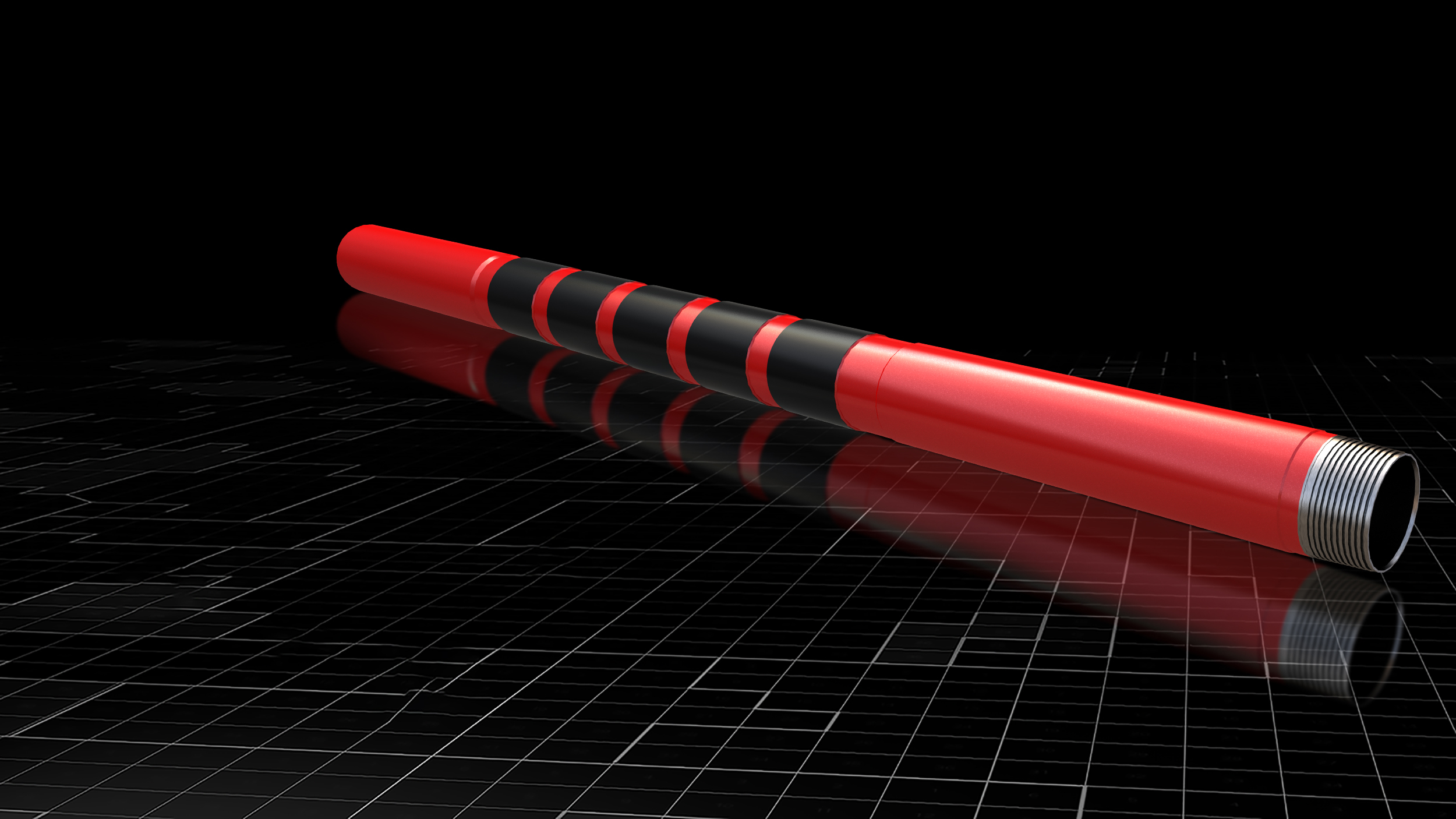

Talk to an expertThe Halliburton VersaFlex expandable liner hanger (ELH) system is the industry’s first fully engineered ELH system designed for use in land, offshore and deepwater applications. Field proven with thousands of installations, Halliburton offers the VersaFlex ELH system as a single unit containing an integral upper tieback receptacle, an ELH and a setting/running sleeve. Simplistic and reliable characteristics are the design basis of the VersaFlex ELH system. “Set-and-forget” sealing capability is made possible by the multiple elastomeric bands, which are hydraulically energized to form a gas-tight seal to the parent casing at the liner top.

Its clean-form design allows a clear flow path for cementing integrity, unsurpassed by any system in its class. The VersaFlex ELH system offers bi-directional anchoring; an overpull test on the setting tool confirms complete anchoring. The system maintains compatibility with conventional liner tubulars and float equipment in cemented liner applications. In non-cemented applications, the VersaFlex ELH system outperforms conventional liner hangers and production packers to deploy liners to the bottom while providing a positive liner-top seal on setting, even in high-angle wellbores.

Regardless of the application, the VersaFlex ELH system offers a wide range of designs that help reduce risks associated with liner deployment, setting and sealing. In addition to the standard VersaFlex ELH system, which works in a variety of cemented and non-cemented applications, VersaFlex ELH technology can be found in these additional designs for special applications:

Delivers a low-to-moderate load bearing without sacrificing its gas-tight sealing capability or reliability

In horizontal and highly-deviated wells, conventional systems can fail simply because of insufficient gravitational weight. This is not an issue for the VersaFlex ELH system; it sets and seals anywhere in the parent casing.

Our high-torque ratings reveal rugged engineering for everything from drill-in with liner applications, to rotation and reciprocation for better mud removal and increased circulation rates. Capabilities are ideal to handle the following, without pulling out of the hole: