Search

Search

Search

Search

LOGIX® automation and remote operations integrated with geosteering software lands well successfully

Download PDFMature Fields

Deploy fully autonomous drilling technology to land the well

Ecuador

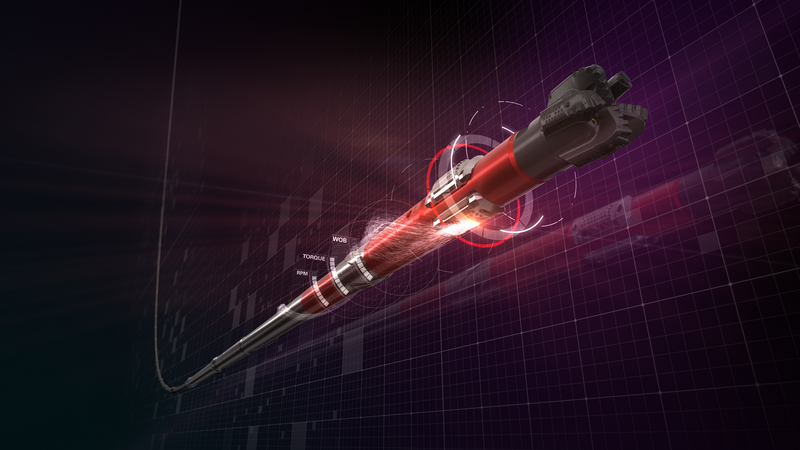

An operator planning to drill the first horizontal well in one of Ecuador’s main platforms faced high uncertainty due to true vertical depth (TVD) variations seen in closeby platforms along the basin. As the introduction of automation technologies transformed the drilling industry, Halliburton Sperry Drilling and the customer agreed to a field trial with the latest advancements. These advancements included automating the integration between formation evaluation data and directional drilling through LOGIX® drilling performance. This job demonstrated the industry’s first fully automated workflow designed to incorporate geosteering-based target changes into the projected well path in real-time.

The well profile was a complex 3D well with a build interval, followed by a 300-ft tangent, and then a build-and-turn interval to reach the reservoir section. The goal was to ensure that geosteering changes were realistic and achievable based on real-time drilling tool performance. This provided the necessary recommendations for the LOGIX® platform to accurately land the well on target. The biggest challenge was to execute an automated workflow in real time between the formation evaluation data while drilling and the directional drilling instructions for the first time in the industry.

The unique process comprises a two-way exchange of data, in which the geosteering target changes use the output of a real-time digital twin, and machine learning (ML) / artificial intelligence (AI) algorithm to define a target that can be drilled. This fully automated process to modify the well plan takes seconds to complete—without requiring any human intervention.

of section drilled without human intervention

°/100 ft in the 300-ft tangent interval

LOGIX automation and remote operations was set up at the rig site and operated by the geosteering team from the customer’s office to remotely drill the curve and the tangent. In the tangent section, the maximum dogleg severity (DLS) was 0.85 deg/100 ft (0.85, 0.36, and 0.35 DLS at the three survey stations), far exceeding the customer requirements to place the electric submersible pump (ESP).

The original well plan was followed until the point when the geosteering team confirmed a change in the geological surface, resulting in a new target to land the well. The updated well path was automatically sent to the LOGIX platform for auto-steering. A combination of ML algorithms were applied to real-time, directional sensor data to determine the real-time steering tendency of the bottomhole assemble (BHA) and the digital twin of the BHA.

By automating the geosteering target changes, the operator was able to:

The Ecuador team successfully executed the first autonomous job to land a horizontal well at the desired target through LOGIX automation and remote operations integrated with geosteering software. A total of 87.4% of the footage was autonomously drilled. The use of ML/AI algorithms insight into real-time (BHA) tendencies resulted in faster reaction time compared to a directional driller making decisions based on manual calculations. This field trial brought the industry a step closer to a more comprehensive autonomous drilling solution—seamlessly integrating formation evaluation data with autonomous directional drilling.

Offers a digital transformation of drilling solutions to reduce operational risks and ensure consistent well delivery.

Automation-enabled platform designed specifically for longer well applications in harsh environments.

Fully digital and web-enabled to monitor and control drilling and logging operations from anywhere