Search

Search

Search

Search

Halliburton establishes successful run history with VersaFlex® and XtremeGrip® expandable liner hanger systems designed to meet various installation challenges

Download PDFMarket dominated by competitors conventional systems

Middle East

In November 2007, Halliburton ran its first VersaFlex® expandable liner hanger system for a major operator in the Middle East. Additional opportunities followed, and by year-end 2022, the number of VersaFlex and XtremeGrip® expandable liner hanger jobs for that operator exceeded 1,000 installations. Throughout this successful run history, Halliburton provided improved tool designs to meet operator expectations and evolving requirements while maintaining the highest levels of service quality across a broad array of applications.

This critical project was the first performed by the operator in the country’s offshore sector. The offshore exploratory well targeted reservoirs in high-pressure/high-temperature (HP/HT) sour-gas formations. The liner hanger system design had to account for the harsh environment and fluid loss concerns during liner deployment to help ensure operation success.

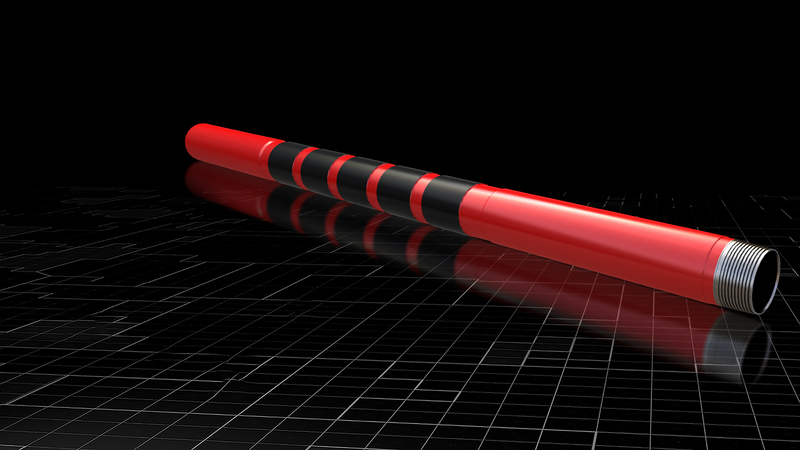

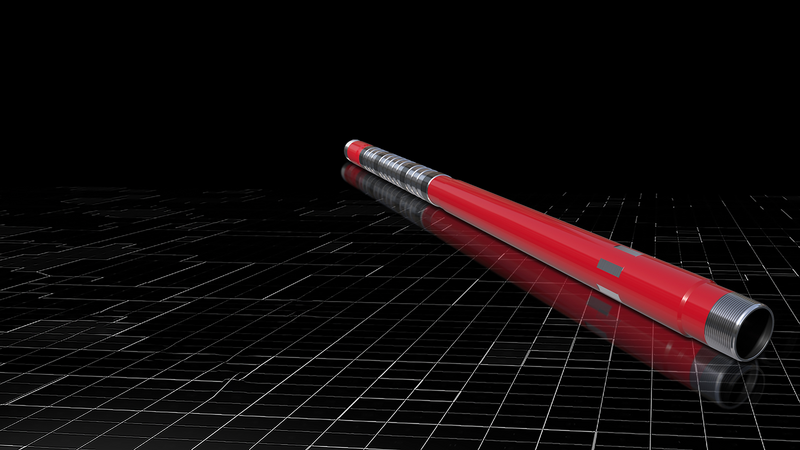

Halliburton proposed an 11 3/4 × 13 5/8-inch XtremeGrip liner hanger system, which provides field-proven, reliable performance in elevated pressures and temperatures. Its clean-form, simple design with a smooth radial flow path allows for an unrestricted bypass area, reducing equivalent circulating densities (ECDs) and potential fluid losses.

installations

issues reaching target depth

asset value

During the journey to 1,000 installations, the local Halliburton team completed numerous managed pressure drilling applications and installation of some of the longest laterals drilled in the region. In 2020, the team designed a well installation that included two liner hanger systems and deployed the region’s first 9 5/8 x 13 3/8-inch XtremeGrip® liner hanger and 9 5/8 x 11 3/4-inch XtremeGrip liner hanger and tieback system. Both systems reached target depth with zero issues and provided the loss zone isolation necessary to achieve the operator’s objectives and enable drilling farther into the production zone.

With onshore and offshore activity in the region expected to increase, growing demand for both expandable and conventional liner hanger systems is also expected. As such, the local Halliburton team deployed the first drop-off systems from the MatchSet® conventional liner hanger portfolio, which replaced the system provided by a competitor, further increasing operator confidence in the Halliburton product line.

Listening to the operator’s challenges, collaborating closely and developing innovative solutions delivered with excellent service quality helped increase operational efficiency and maximize asset value.

Field-proven, total system approach to liner installations

High-performance ELHs with enhanced hang-weight capabilities in elevated temperatures

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications