Search

Search

Search

Search

CorrosaLock™ and CorrosaCem™ cement systems successfully placed on production liner in CO2 storage well

Download PDFCCUS well

Corrosion-resistant cement solution for CO2 storage well

USA

With the industry focus on a low-carbon future, carbon capture, utilization, and storage (CCUS) is a rapidly growing market. Regulatory bodies, such as the Environmental Protection Agency (EPA), require operators to fulfill specific and rigorous requirements to obtain permits for CCUS wells.

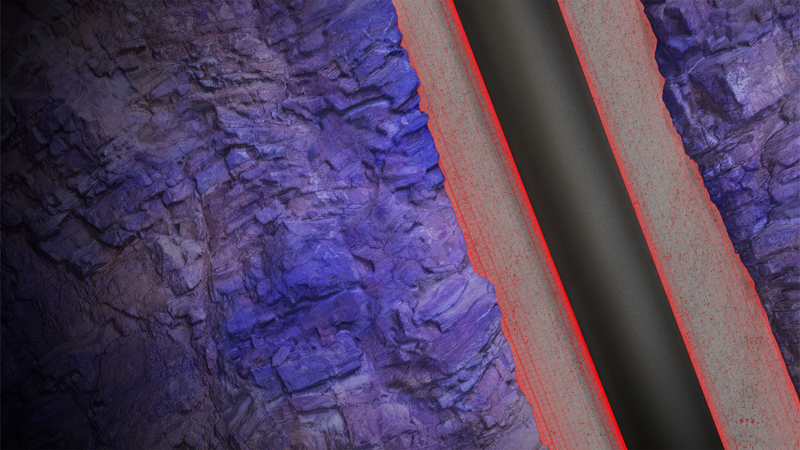

An operator in North America required a CO2 corrosion-resistant cement system to obtain a CCUS well permit. The primary purpose of this well is to store the CO2 captured from a nearby treating facility. The CO2 is a natural byproduct from natural gas production of nearby wells. Injection of excess CO2 back to the subsurface formation was planned. Because of a relatively low fracture gradient in the injection section, lost circulation also posed a challenge.

To address the corrosive nature of the injected stream, along with slim equivalent circulating density (ECD) margins, a relatively low-density/low-rheology 13.5-lbm/gal CorrosaLock cement system lead and 14-lbm/gal CorrosaCem cement system tail were deployed. The CorrosaLock corrosion-resistant system is a composite mixture of Portland-based cement and Welllock® resin additive. The resin component helps enhance the system’s mechanical properties by increasing elasticity, which helps mitigate the effect of cyclic loading on the cement sheath. Inclusion of resin also reduces the permeability and porosity of the composite system, which enhances corrosion resistance.

The CorrosaCem cement system is a reduced Portland system with cement replaced by supplementary cementitious materials (SCMs) that do not react with CO2 to help improve CO2 corrosion resistance. Additives to reduce permeability and further enhance corrosion resistance were also included. Additionally, CorrosaCem cement is designed with additives that enhance elasticity to help improve resistance to mechanical failure caused by cyclic injection operations.

bbl CorrosaLock cement lead placed

bbl CorrosaCem cement tail placed

Confirmed cement coverage

Full circulation was maintained throughout pumping and displacement operations. A total of 64 bbl of CorrosaLock cement lead and 60 bbl of CorrosaCem cement tail slurries were effectively placed over the entire length of the liner. Low-pressure and high-pressure liner top tests were successfully performed. Additionally, a successful negative test was performed. A cement bond log (CBL) verified the quality of the cement sheath behind the liner and confirmed excellent cement coverage throughout the wellbore.

Provides improved resistance to CO₂, lower permeability, and increased elasticity in comparison to conventional Portland cement systems

Tailored to improve chemical resistance to CO₂ and enhanced mechanical properties that minimize the impact of cyclic loading on the cement barrier integrity.

Deep-penetration, high-performance sealant ideal for carbon storage, chemical disposal wells, and permanent plug and abandonment.