Search

Search

Search

Search

In many underground injection operations, the distribution of injected fluids like supercritical CO₂ is often unknown and varies over time due to complexity

In many underground injection control operations, injection allocations across the reservoir interval are not measured and thus are unknown. This is further complicated for a fluid like supercritical carbon dioxide (CO2) because injectivity is expected to vary significantly over time due to reservoir dynamics like pressure cycling and salt precipitation. If anything, these dynamics place a higher priority on storage operators measuring CO2 injectivity at the highest possible spatial resolution. This allows plume models to be optimally history-matched with time-lapse seismic imaging. The result is higher confidence in forecasting plume migration during and after injection operations.

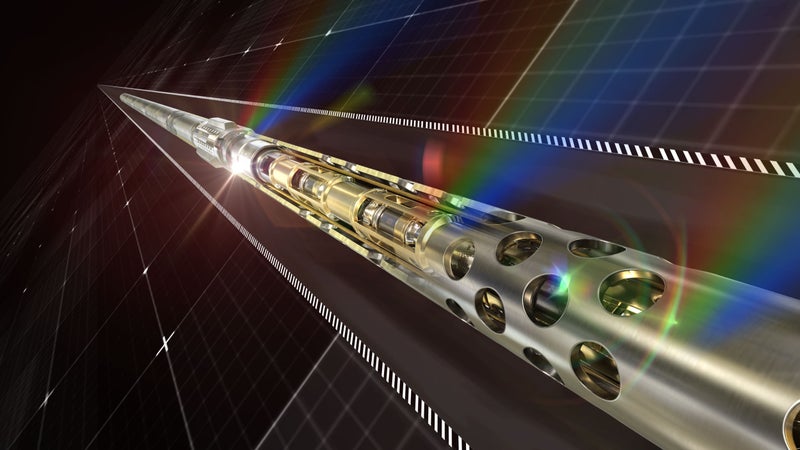

Over the past 15 years, the oil and gas industry has seen the rapid adoption of fiber optic sensing for downhole monitoring of distributed temperature and acoustic sensors along the entire wellbore for a wide variety of production and injection applications. Fiber optic cables installed behind casing or on tubing, along with injection and tubing pressure and temperature gauges, provide crucial downhole data about the reservoir dynamics. In unconventional wells, fluids and proppants were pumped in stages without any feedback about conformity or stimulated reservoir volume. This raised questions about where oil and gas production was really coming from. In recent years, fiber optic sensing has “turned on the lights” downhole. Its real-time analysis now advises on stimulation operations down to the perforation cluster interval, improving our understanding of where oil and gas are produced.

Acoustic analysis tools that pinpoint costly wellbore leaks by analyzing sound waves that describe flow patterns in the formation and casing.

Industry-validated workflows designed for efficient and cost-effective CO2 storage projects across multiple scales.

Deep azimuthal resistivity measurements for multilayer mapping and precise well placement.

Halliburton collaborates and engineers CCUS lifecycle solutions to optimize carbon storage with advanced engineering and leading technology.

Explore