Search

Search

Search

Search

Operating expenses and deferred production were significantly reduced on three wells

Download PDFSand produced caused random performance levels and early ESP failure.

Middle East

The SandRight Solids Fallback Preventer was installed in three identified wells as a pilot.

Run life improved as much as 380+%:

An operator in the Middle East sought to improve its return on investment (ROI) by reducing deferred production and operating expense (OPEX) through increased electric submersible pump (ESP) run life and drawdown. Large quantities of sand produced from the unconsolidated reservoir were identified as a primary cause of irregular performance and early ESP failures.

Sand produced from an ESP will naturally fall back during shutdowns, settling on the first stages of the upper pump. When the ESP system is restarted, this accumulated sand can cause a hard startup, overstressing the shaft and leading to premature mechanical failure. The operator identified three wells with a history of premature failure due to frequent shutdown and hard restart episodes, with one well experiencing a broken pump shaft. Previous mitigation efforts were ineffective and used tools that required a costly rigless job for ESP flushing.

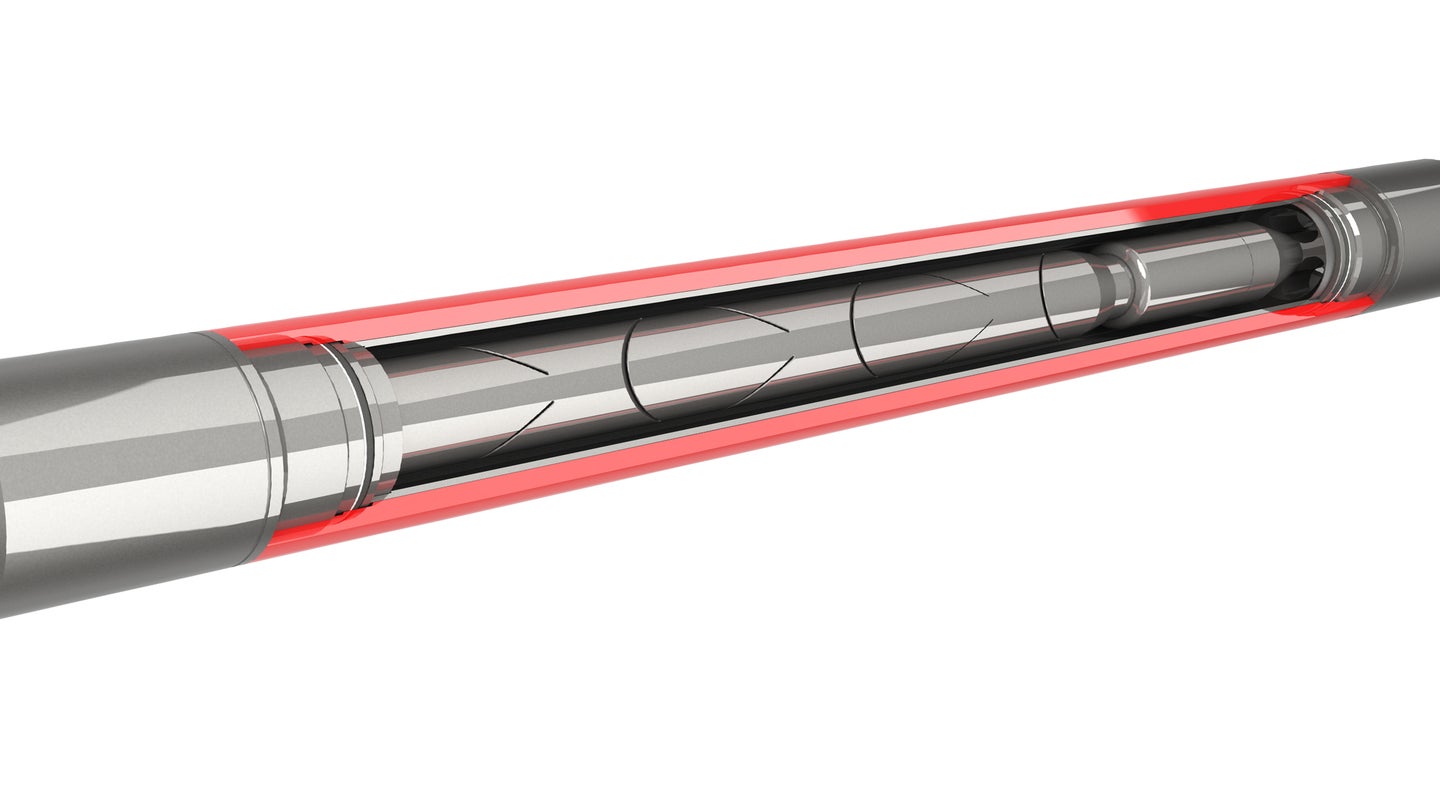

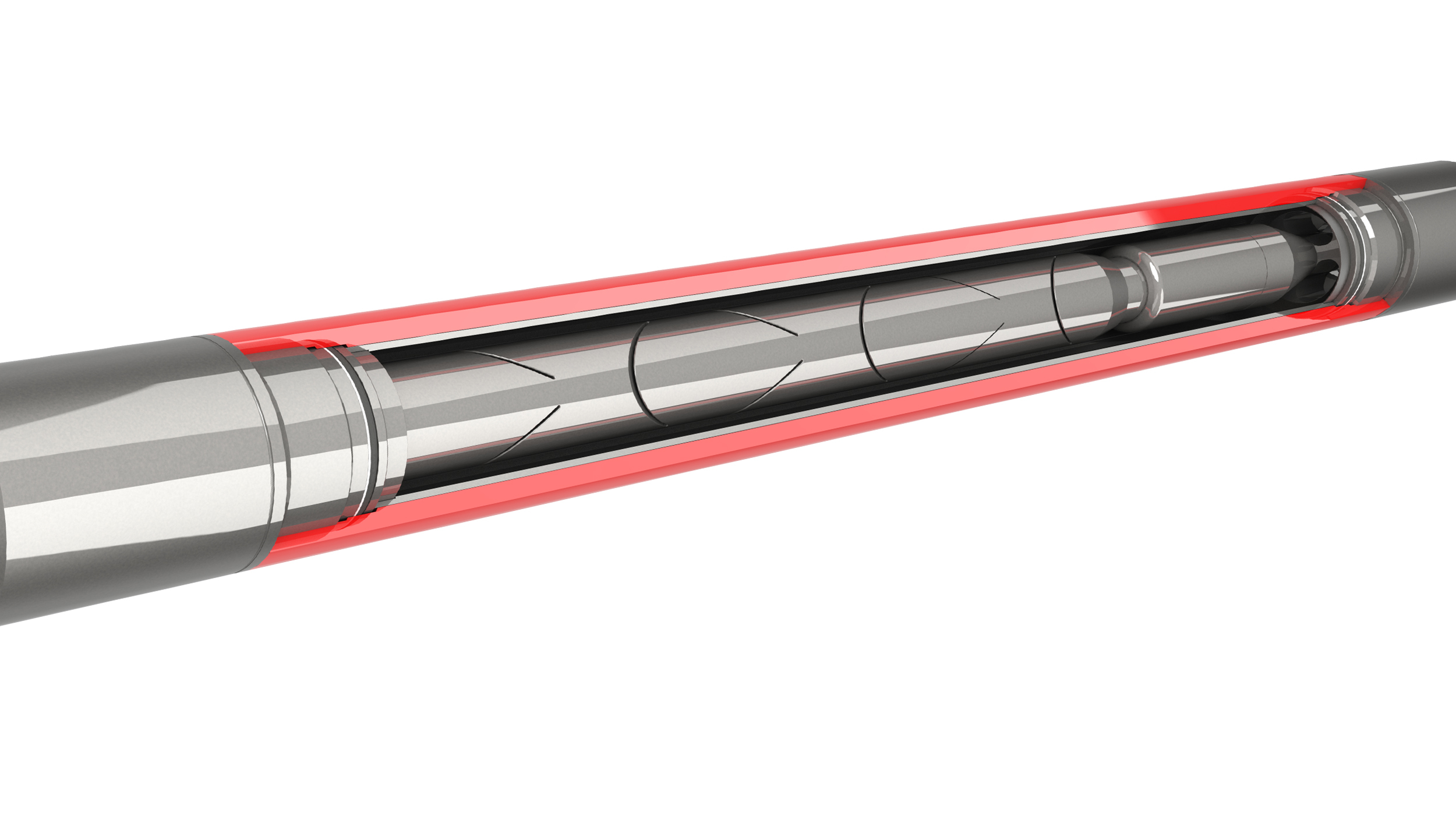

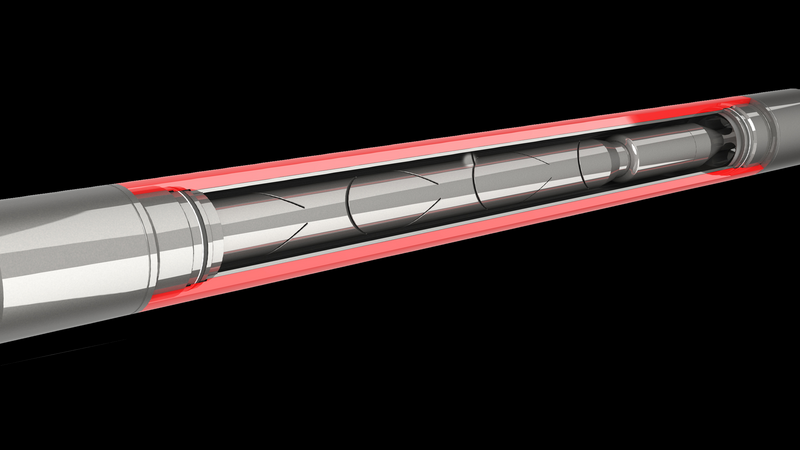

The SandRight solids fallback preventer was installed as a pilot in the three previously identified wells. SandRight deters damaging solids from entering the ESP during power shutdown events. Its innovative internal design forms a sand bridge in the annulus of the tool, stopping the sand from entering the pump and preserving the ESP system. During startup, the pump fluid will flush the sand from the tool and carry it back to the surface. Unlike other solutions in the industry, it maintains the ability to execute through-tubing chemical treatments while resisting paraffin/scale buildup using superior materials. Drawing from cross-product line experience in fracking and fluid-proppant transport, the tool was specially designed to be compact and easily integrated into our ESP production system.

All three pilot wells were able to restart without any signs of a hard start or damage to the ESP. Run life for the wells improved by 380+%, saving the operator costly downtime and deferring production. This efficient, reliable, long-lasting sand management tool delivered on the operator’s goal to maximize asset value.

Run life improved

Days of improved run life

Days of improved run life

Days of improved run life

The SandRight® tool prevents solids from entering the ESP system during shutdown events, eliminating overstressed motors and accelerated pump wear when restarting the system.