Search

Search

Search

Search

SandRight solids fallback preventer significantly reduced operator’s total cost of ownership

Download PDFExtend ESP system run life

Colombia - South America

An operator in Colombia wanted to improve its return on investment (ROI) by reducing an asset’s deferred production and OPEX through increased electric submersible pump (ESP) run life and reservoir drawdown. The field is well known for its tendency to produce a large amount of sand from the unconsolidated reservoir. After trying different artificial lift methods and existing tools to mitigate the sand falling back into the ESP during shutdowns, the operator was still unable to improve ROI due to numerous ESP failures.

Sand produced through the ESP will naturally fall back during shutdowns, accumulating in the first stages of the upper pump and causing hard startups when the ESP system is restarted. This can overstress the shaft, leading to premature mechanical failures in the pump. A large amount of sand with a small particle size has the potential to jam traditional sand management tools, leading to random levels of performance, which this operator experienced. A more reliable sand management solution was clearly needed.

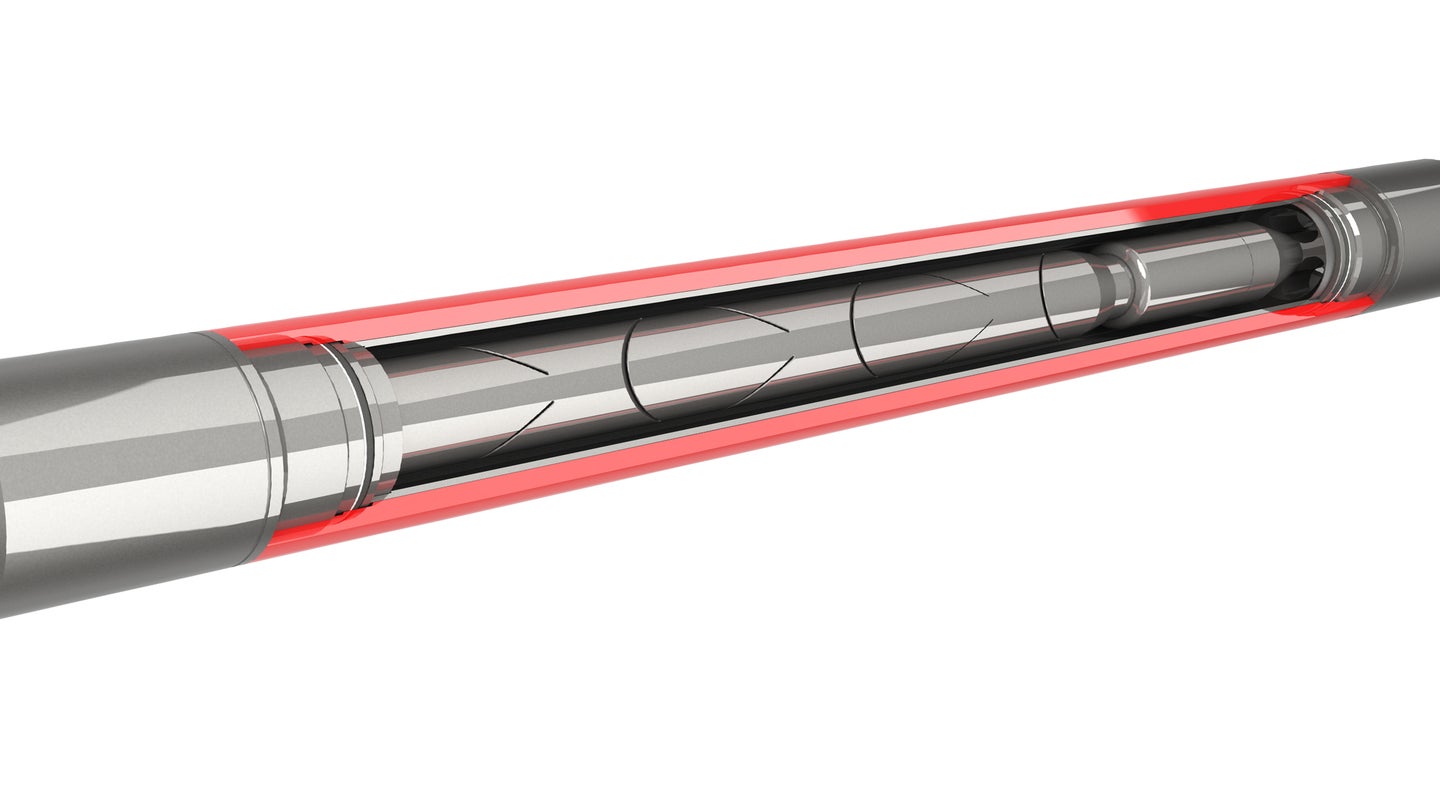

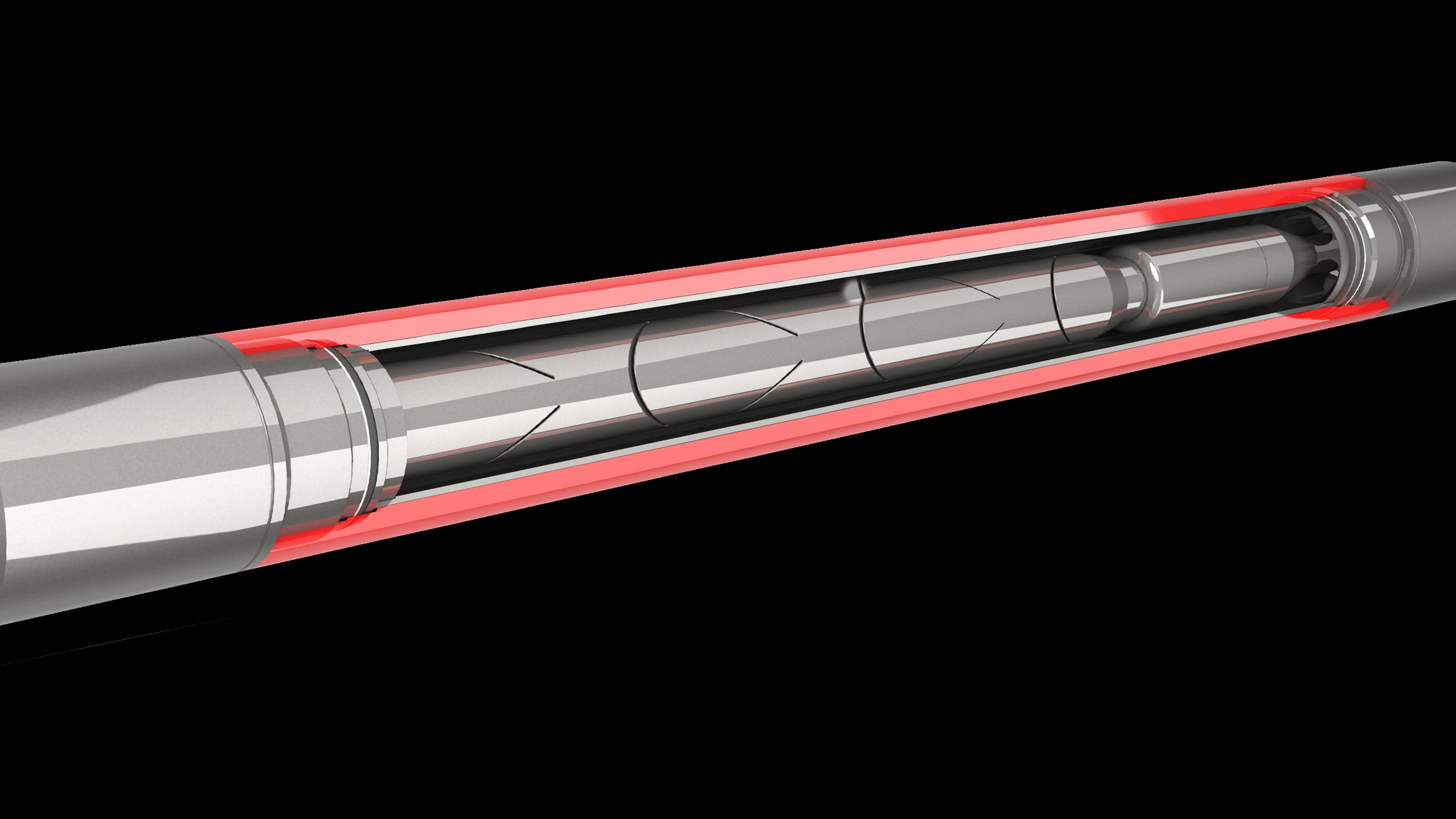

The SandRight® solids fallback preventer was implemented for its ability to eliminate hard startups and to improve ESP run life. Its innovative internal design forms a sand bridge in the annulus of the tool, thereby stopping the sand from reentering the pump. During startup, the pump fluid will flush the sand from the tool and carry it back to the surface. The insulated poppet valve design has the unique capability to open under differential pressure, thus, avoiding tool jamming. Additionally, the SandRight tool’s slim profile reduces the risk of cable damage during ESP installation.

The SandRight solids fallback preventer allowed the wells to restart without any sign of a hard start or damage to the ESP. This more efficient, reliable, and longer-lasting sand management tool delivered the operator’s goal of maximizing asset value. An additional 10 ESPs have now been deployed in the same field with the SandRight solids fallback preventer installed, demonstrating the consistent, outstanding performance of this technology.