Search

Search

Search

Search

765-day run pulled for downsize as production declines: top pump passes inspection despite heavy evidence of solids.

Download PDFUnconventionals

Solids above ESP production tubing can cause catastrophic failure.

West Texas, Permian Basin

Unconventional Permian Basin wellbores are challenging to produce because they are often highly corrosive and can produce massive volumes of erosive formation fines and frac sand. Poor quality power means shutdowns can occur frequently and for extended periods.

In addition to corrosion and erosion, shutdown events can shorten ESP run life. When an ESP is shut down, solids hovering above the ESP’s production tubing are a major issue, especially in unconventional applications. These solids fall back to the pumps and become lodged in the pump stages. Restart attempts can overstress motors, accelerate pump wear, overheat cable, and/or result in catastrophic failure.

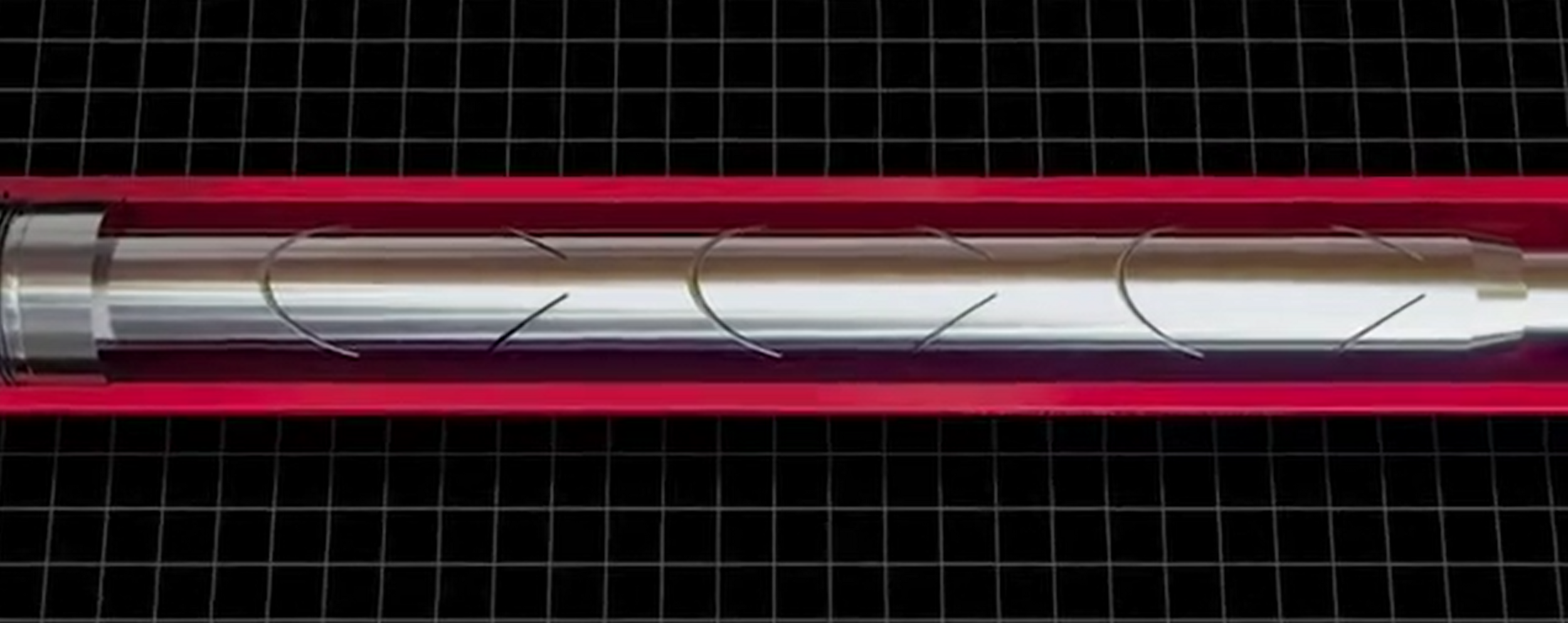

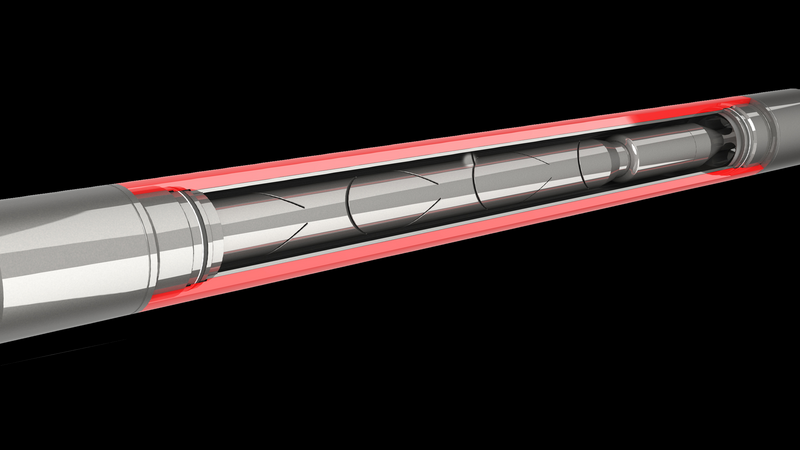

The SandRight solids fallback preventer was developed with Halliburton’s frac engineers to protect the ESP during shutdown events. It uses a unique sandbridge phenomenon to restrict the sand from falling back into the tool. Once power resumes or the shutdown event has been resolved, the ESP system can return to stable operations without damage caused by a hard restart. Compact and easily deployed, SandRight’s design includes metallurgy and ceramic coating to provide higher abrasion and corrosion resistance while resisting paraffin and scale build-up.

As an early adopter of the SandRight technology, the operator has installed over 150 units without failure. In this case, during its 765-day run life, the well experienced three frac hits that dumped heavy volumes of abrasives into the produced fluid, and the ESP was shut down 110 times, mostly due to poor power quality.

When production began declining, the operator decided to downsize the system and pull the well. During the teardown analysis, the tubing was plugged off with debris, and there was evidence of erosion and corrosion from the 500 ppm H2S. Despite these challenges, the top pump passed inspection, reinforcing SandRight’s efficacy in protecting ESPs from solid fallback.

Day run life

Frac hits

Power-related shutdowns

Saved ESP

The SandRight® tool prevents solids from entering the ESP system during shutdown events, eliminating overstressed motors and accelerated pump wear when restarting the system.