Search

Search

Search

Search

Accurate production profiling information for critical well decisions

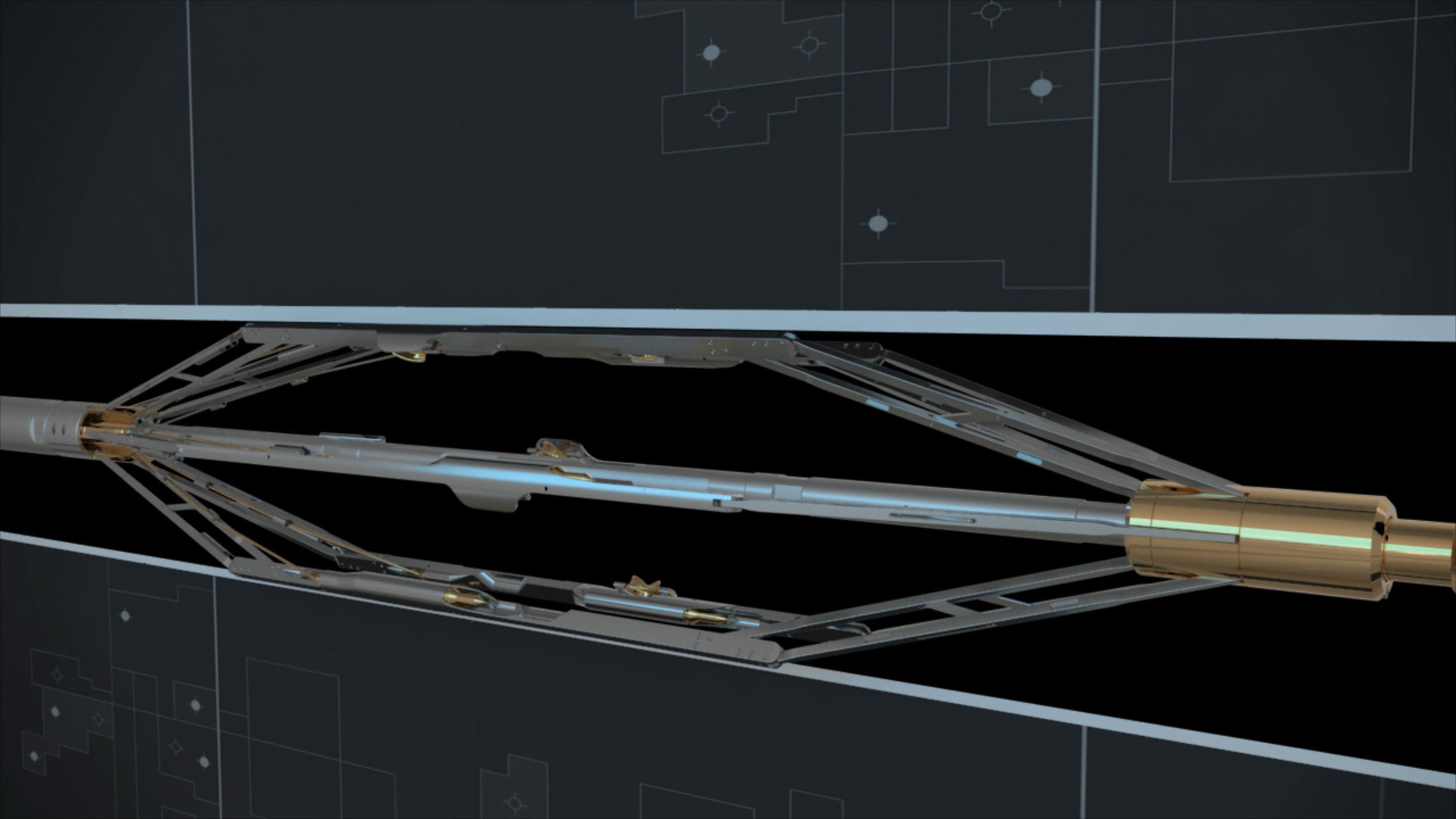

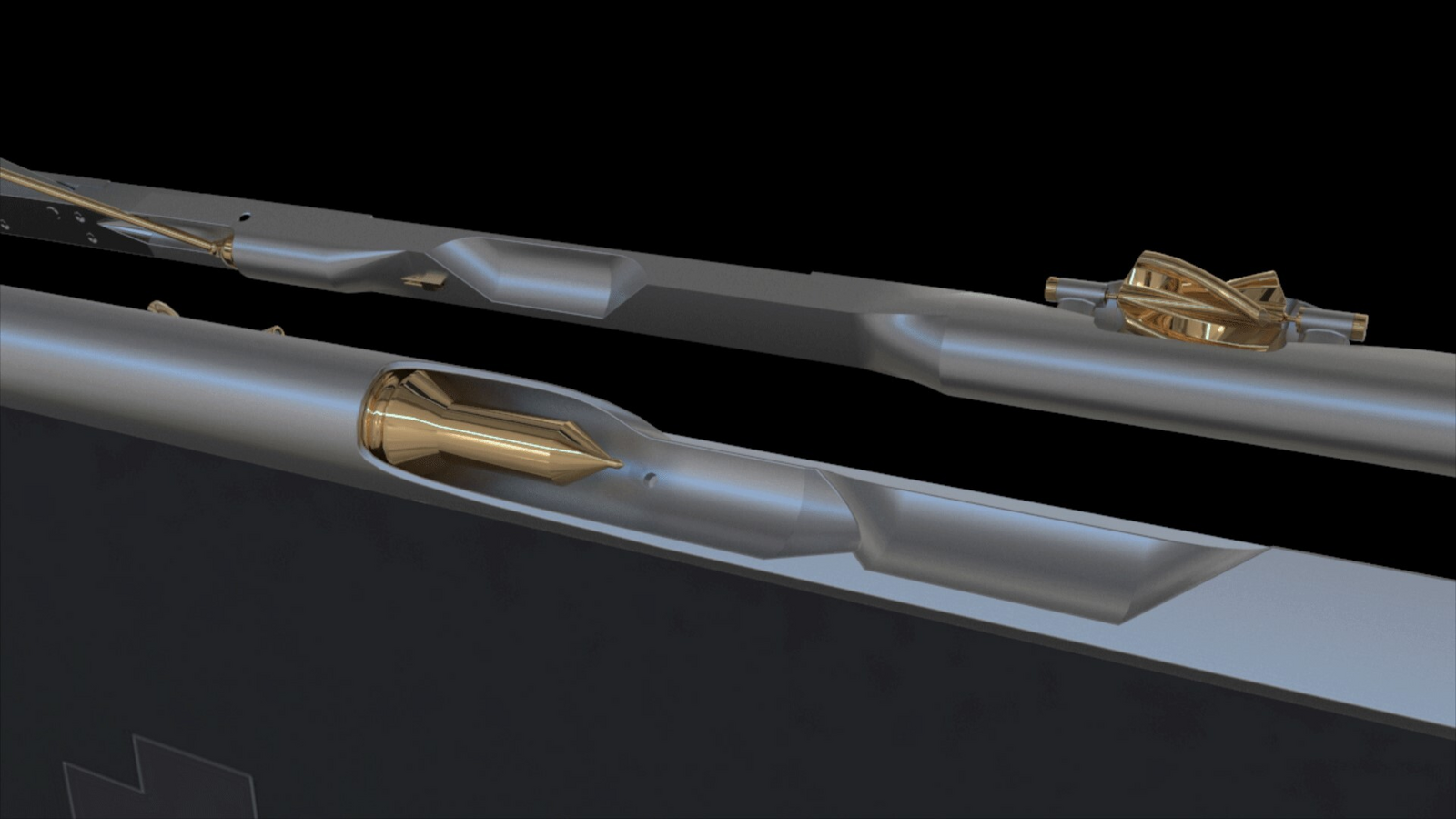

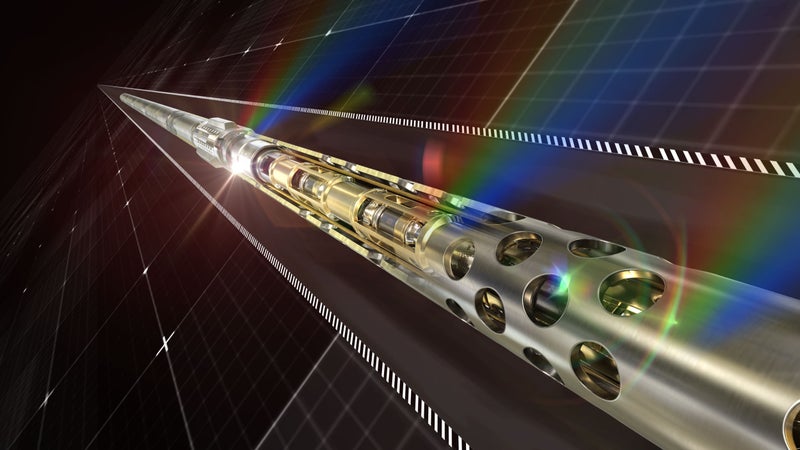

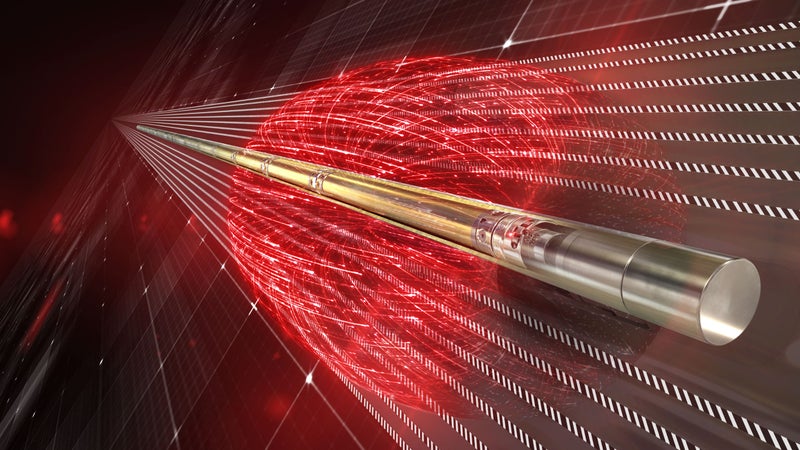

Talk to an expertIntelliFlow array production logging service provides cross-sectional measurements in the wellbore for flow properties and characteristics. The tool quantifies multi-phase flow with resistivity, capacitance, and optical fluid ID sensors. These are co-located on each of six arms arranged in a circumferential pattern placed around the wellbore. A micro-spinner is included on each arm for fluid velocity of each phase. Together these sensors provide a wealth of critical data to analyze reservoir flow and monitor production better.

Advanced technology for optimal production insights

00:35

phase solution - locate gas, oil, and water production

arms in a radial configuration

inches separate the upper-most and bottom-most sensors

total tool sensors

When paired with additional Intelli-portfolio services, the IntelliFlow array production logging service provides unrivaled production monitoring capabilities. The detailed image of the fluid flow and its relation to the reservoir gives operators the insight needed to improve production.

Acoustic analysis tools that pinpoint costly wellbore leaks by analyzing sound waves that describe flow patterns in the formation and casing.

Accurately pinpoint casing defects and metal corrosion in up to seven tubular strings throughout the well.

Monitor reservoirs to increase production, improve recovery, and find bypassed pay.