Search

Search

Search

Search

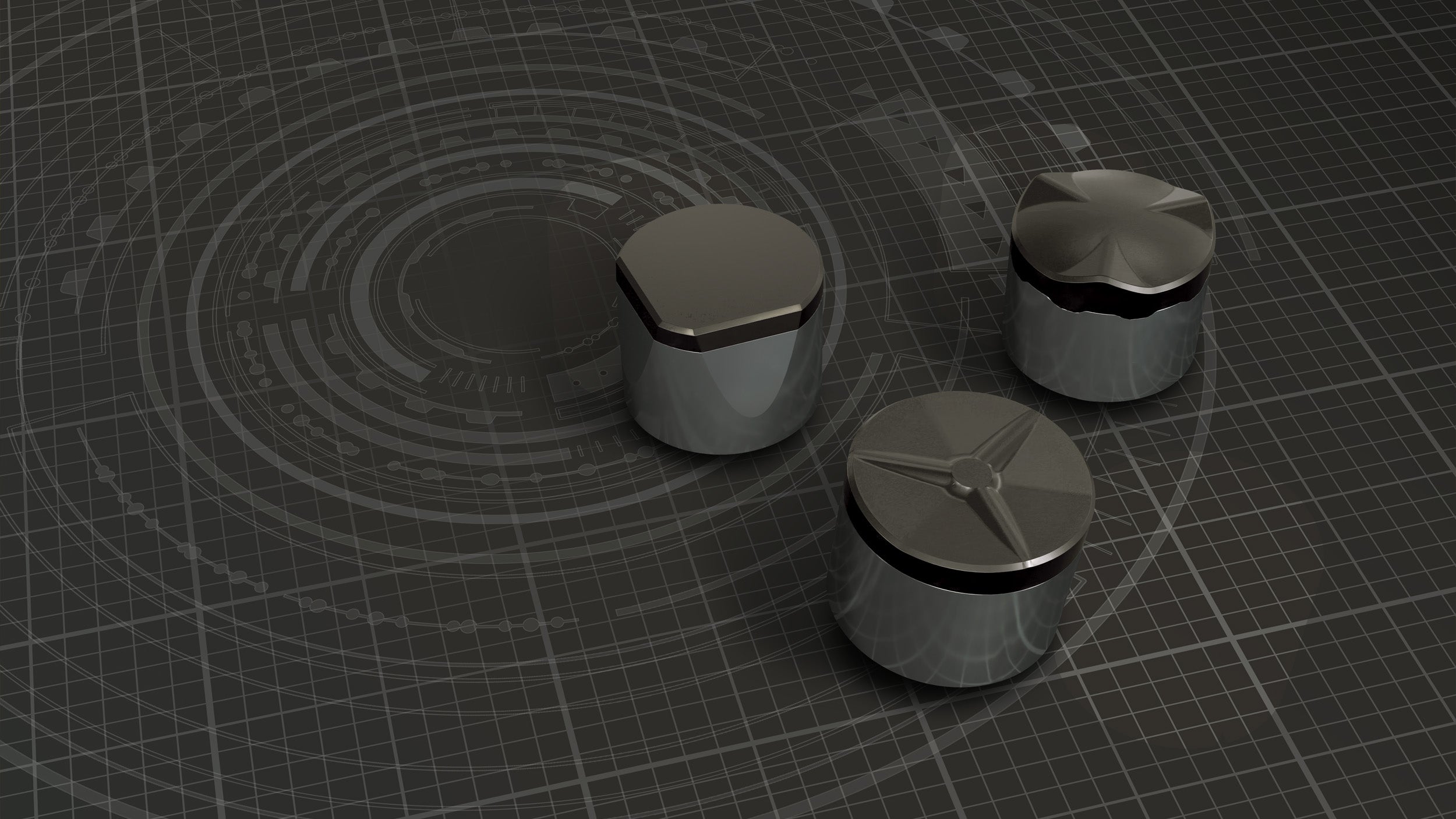

The Geometrix 4D-shaped cutters offer unique geometries compared to traditional cylinder cutters, resulting in more efficient drilling. The various shapes in this offering provide solutions for improved chip flow, reduced friction, and minimized thermal degradation. This is another way the Design at the Customer Interface (DatCI™) process helps reduce drilling costs by delivering custom solutions tailored to specific applications worldwide.

Designed with higher contact stress along the cutter rock interface to fail rock more efficiently, enhanced edge profile for efficient cuttings removal and evacuation, and domed center for increased durability.

Features a sharper edge for more efficient shearing, a relieved face to reduce friction, and centralized chip-breaker to deflect cuttings across the diamond face.

The Machete full cylinder scribe cutter axially pre-fractures rock through point loading in hard, brittle applications. The geometry improves thermal stability by remaining sharper during the drilling process.