Search

Search

Search

Search

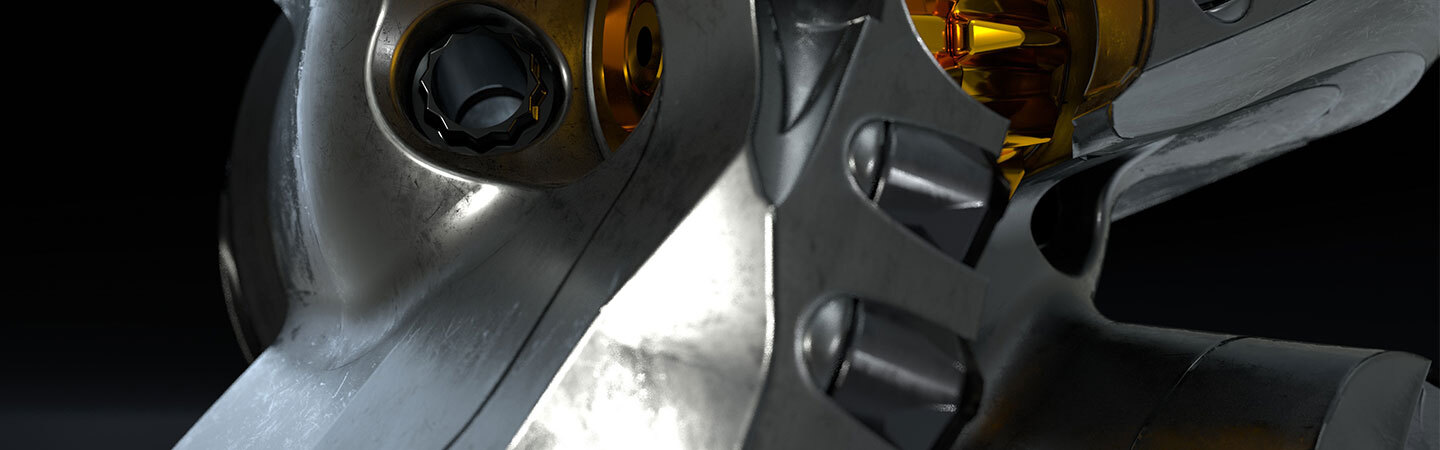

Cerebro® electronic data capture at the bit mitigates stick-slip, while improving ROP and bit conditions

Download PDFUnconventionals

Reach the casing point, through multiple formations, in a single run

Mid-Continent

The 8-3/4 inch vertical interval in western Oklahoma consists of multiple formations of varying strengths, resulting in tough transition zones. This interval is drilled utilizing a steerable motor assembly and can have tangents as high as 15 degrees in inclination.

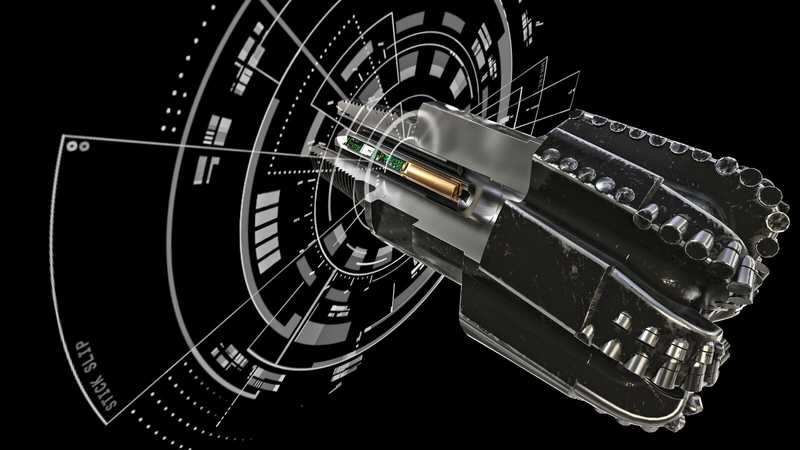

The key challenge for this application was maximizing the rate of penetration (ROP) in the softer upper sections while providing enough durability to drill through the formation transitions in the lower portion of the interval. Typically, dull bits in this interval had multiple chipped and broken cutters, hinting at extreme drilling vibrations encountered while drilling through formation transitions. The goal was to make it to the casing point in a single run and to maintain directional control in the tangent.

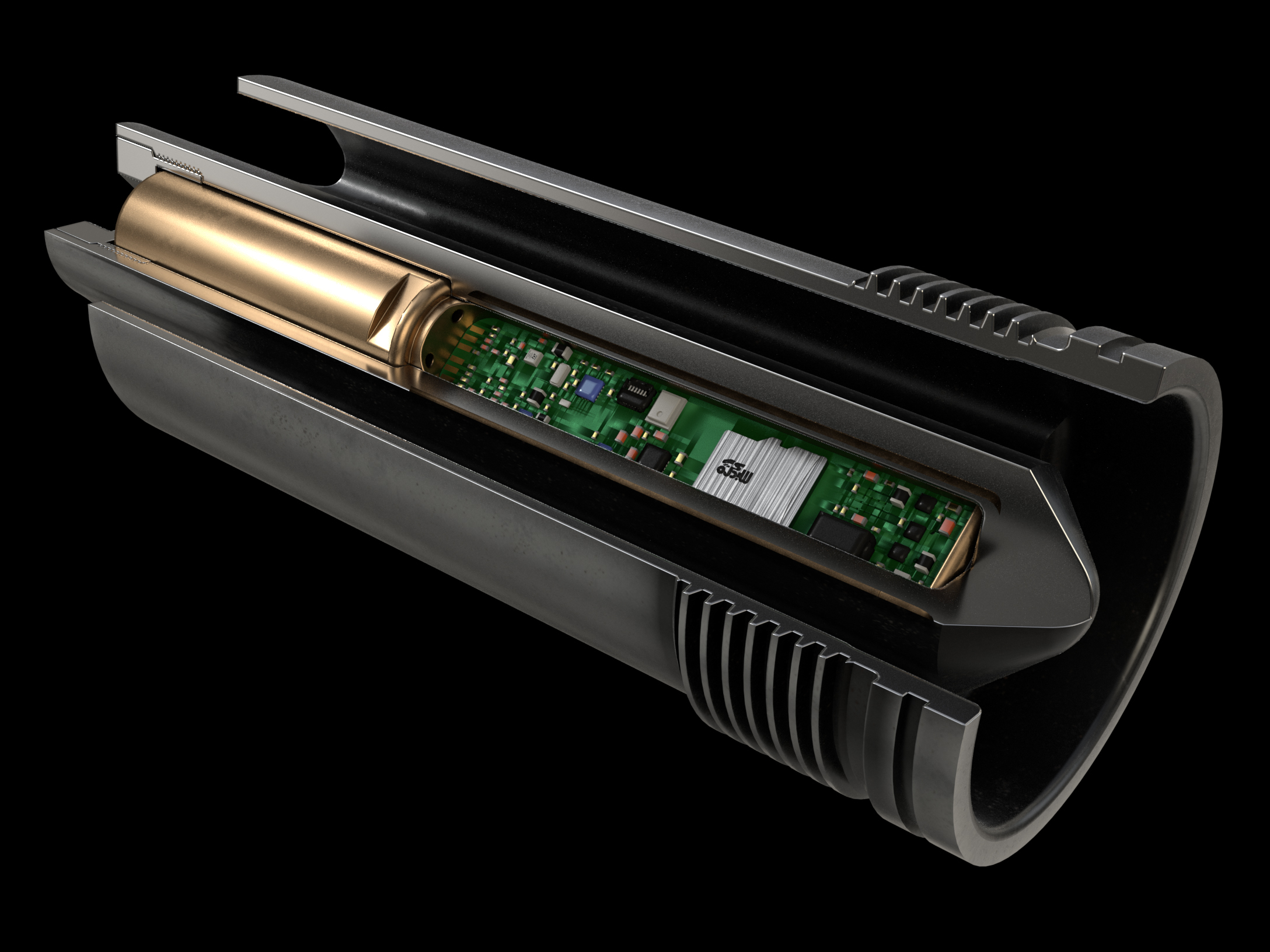

The Cerebro® in-bit sensor was used on three different vertical runs to measure downhole vibrations. This data, combined with surface drilling data, generated a complete picture of the environment that the drill bits encountered. Utilizing the data from all three wells, a pattern was identified that linked the reduction of surface RPMs near expected formation transitions to an increase in stick-slip, and vibration, and to a decrease in ROP. To mitigate the stick-slip and to improve ROP and bit conditions, a recommendation was made to maintain surface RPMs through these transitions.

A follow-up run with the Cerebro in-bit sensor, applying the new recommendations, showed a marked decrease in stick-slip vibrations through the transition zones, resulting in higher ROP and a better looking bit.

Analyze and understand drill bit performance quicker and more efficiently with the Cerebro™ in-bit sensor.