Search

Search

Search

Search

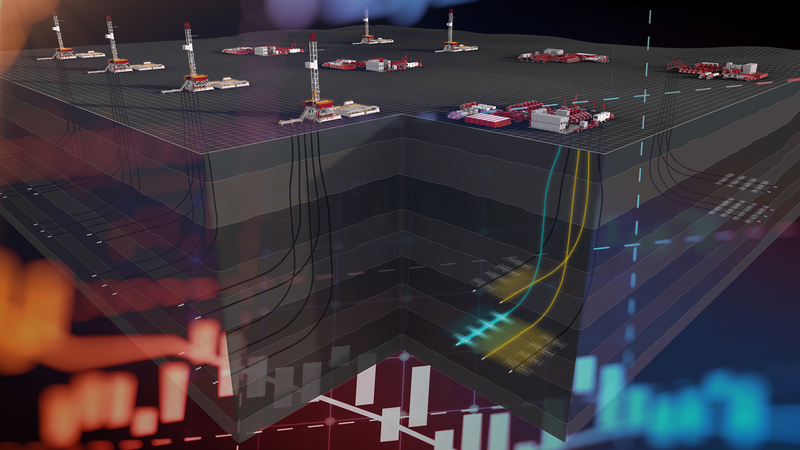

Halliburton made fiber a practical option for routine fracture monitoring so you can benefit from actionable insights on more wells across your asset.

Talk to an expertTrying to understand what’s happening downhole while fracturing is complicated. The solution shouldn’t be. At Halliburton, we simplified fiber installation by engineering out unnecessary complexity and cost for a more practical fracture monitoring solution that complements your well factory approach.

We reduced fiber installation from an average of six months down to two weeks—making fiber more manageable and easier to incorporate into your overall fracture design. By reengineering our downhole equipment to fit standard North America wellbores and hole sizes, we eliminated undesired wellbore changes, such as requiring a larger hole, which impacts drilling schedules and prolongs planning cycles.

LOW-COST FIBER, ZERO IMPACT TO OPERATIONS

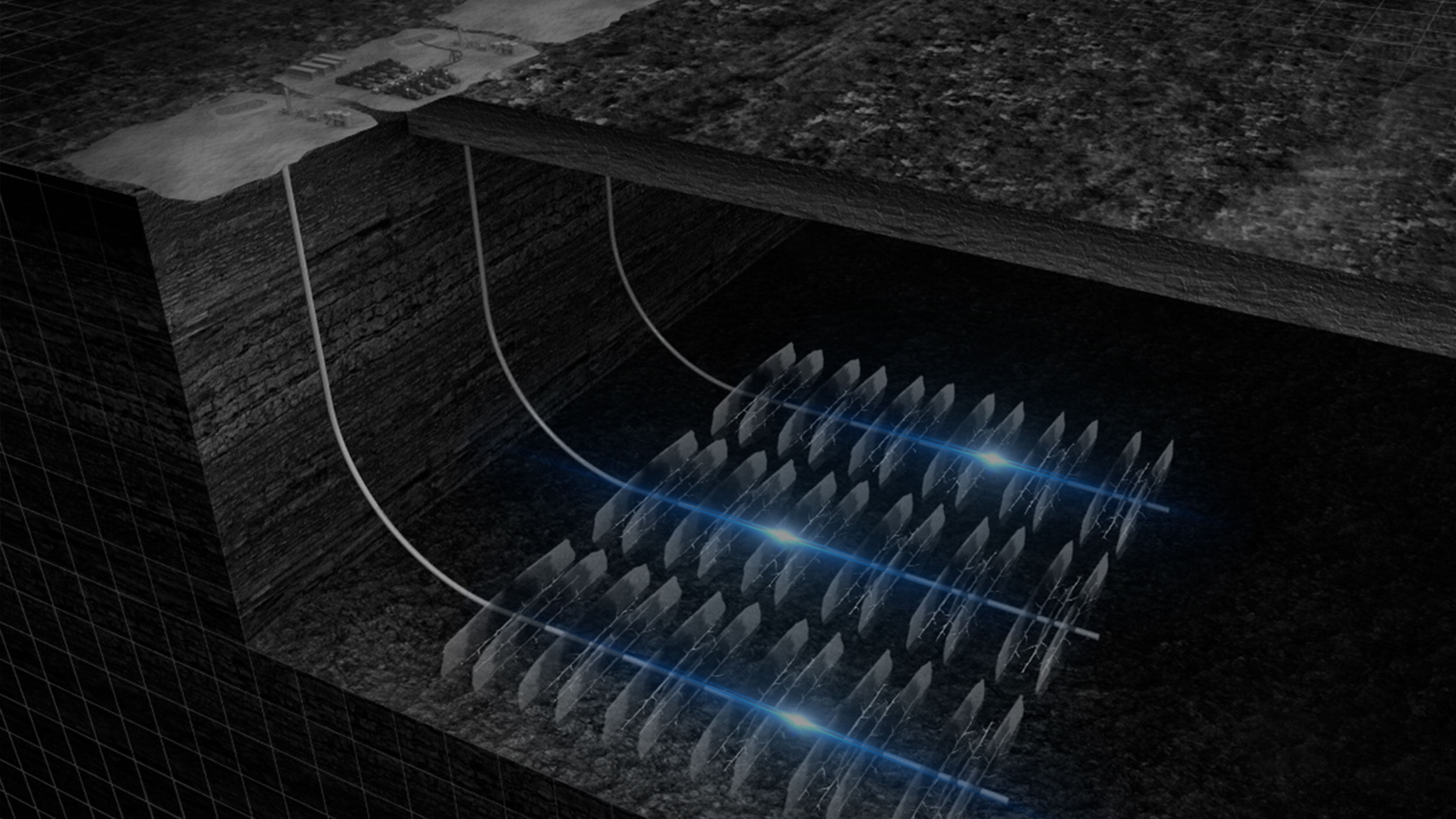

Halliburton introduces ExpressFiber™, a single-use fiber optic cable that offers direct cross-well measurements, at a price point that enables fracture monitoring on every well pad.

Explore ExpressFiberIndirect cost eliminated

From planning to installation

Eliminated by running In standard hole sizes

Wireline mapping runs required

We engineered $600,000 in indirect costs out of the installation process by simplifying the complex design process—making fiber an affordable option for fracture monitoring. Eliminating the need for a larger hole allows us to reduce cost of ownership by at least $200,000, and incorporating FIBERSIGHT® Map fiber locating sensors takes away the cost and risk associated with an additional mapping run.

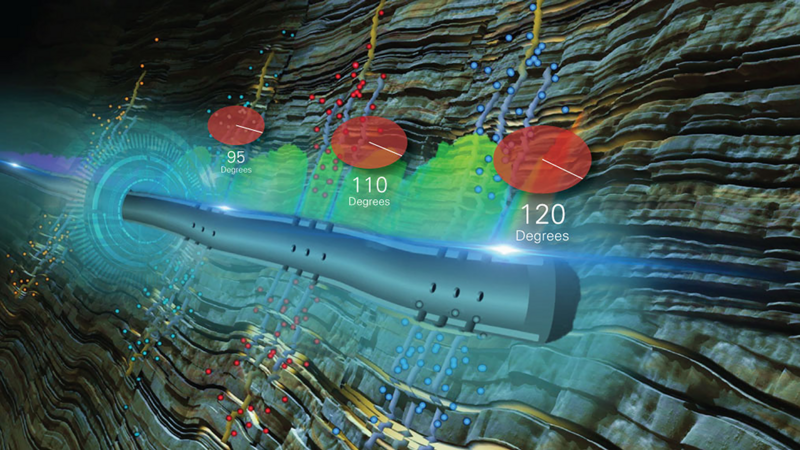

For fiber to truly be practical, terabytes of data must be put to practical use. Our processing and visualization transforms traditional fiber optic data into real-time actionable insights that drive business-relevant answers, such as understanding where your proppant is going and whether you’re interacting with another well.

Technology Spotlight

FIBERSIGHT® map delivers:

The ExpressFiber disposable fiber cable is an economic, low-risk fiber solution for cross-well monitoring that provides direct measurement of well interference.

Enabling cable orientation without the need for wireline mapping.