Search

Search

Search

Search

Halliburton introduces a multi-level suite of pressure optimization solutions to achieve well objectives within complex pressure environments

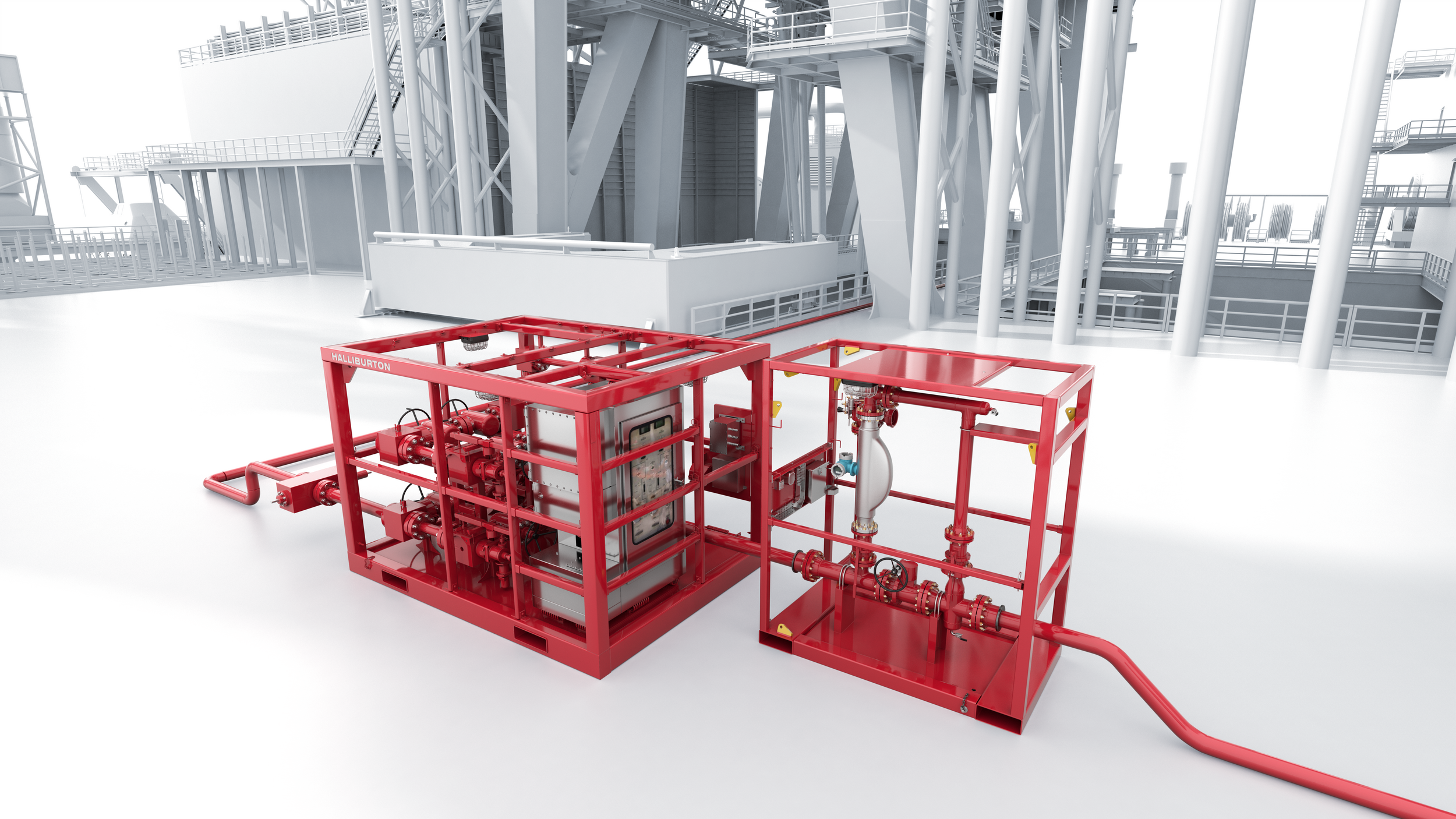

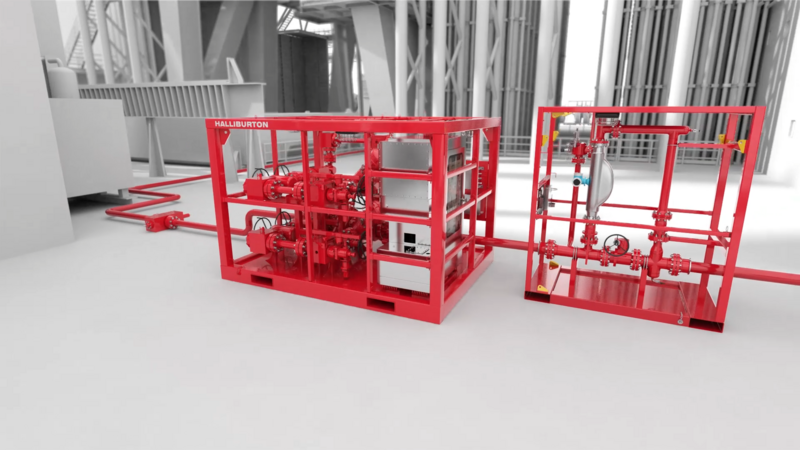

Contact an expertWe deliver customized solutions for managed pressure drilling and full underbalanced drilling programs. When facing critical pressure scenarios that make conventional drilling difficult or impossible, operators rely on Halliburton to achieve challenging well objectives with greater efficiency.

By integrating managed pressure solutions into their drilling program, operators can attain better formation pressure control and stability, higher ROP, faster tripping speeds, increased HSE performance, and lower drilling costs. Halliburton helps turn challenges into productivity.

STRATEGIC COLLABORATION

Our strategic collaboration with Oil States Industries, Inc. combines two award-winning technology sets to provide customers with an effective and flexible MPD product-service combination to access greater operational efficiencies safely.

READ PRESS RELEASE

Case Study: Utica Shale

Halliburton software used to safely extend production interval for operator while reducing personnel and environmental risk.

See Case Study

A key part of pressure control, Halliburton rotating control devices are the first line of defense against fluid loss during critical operations.

Explore

Enabling technology that can accomplish efficiency goals while mitigating drilling risks.

Explore

The Halliburton e-cd™ circulating device is an Eni-patented system used in managed pressure drilling operations

Explore

Halliburton's underbalanced drilling service delivers high-performance drilling solutions while focusing on improving reservoir recovery.

Explore