Search

Search

Search

Search

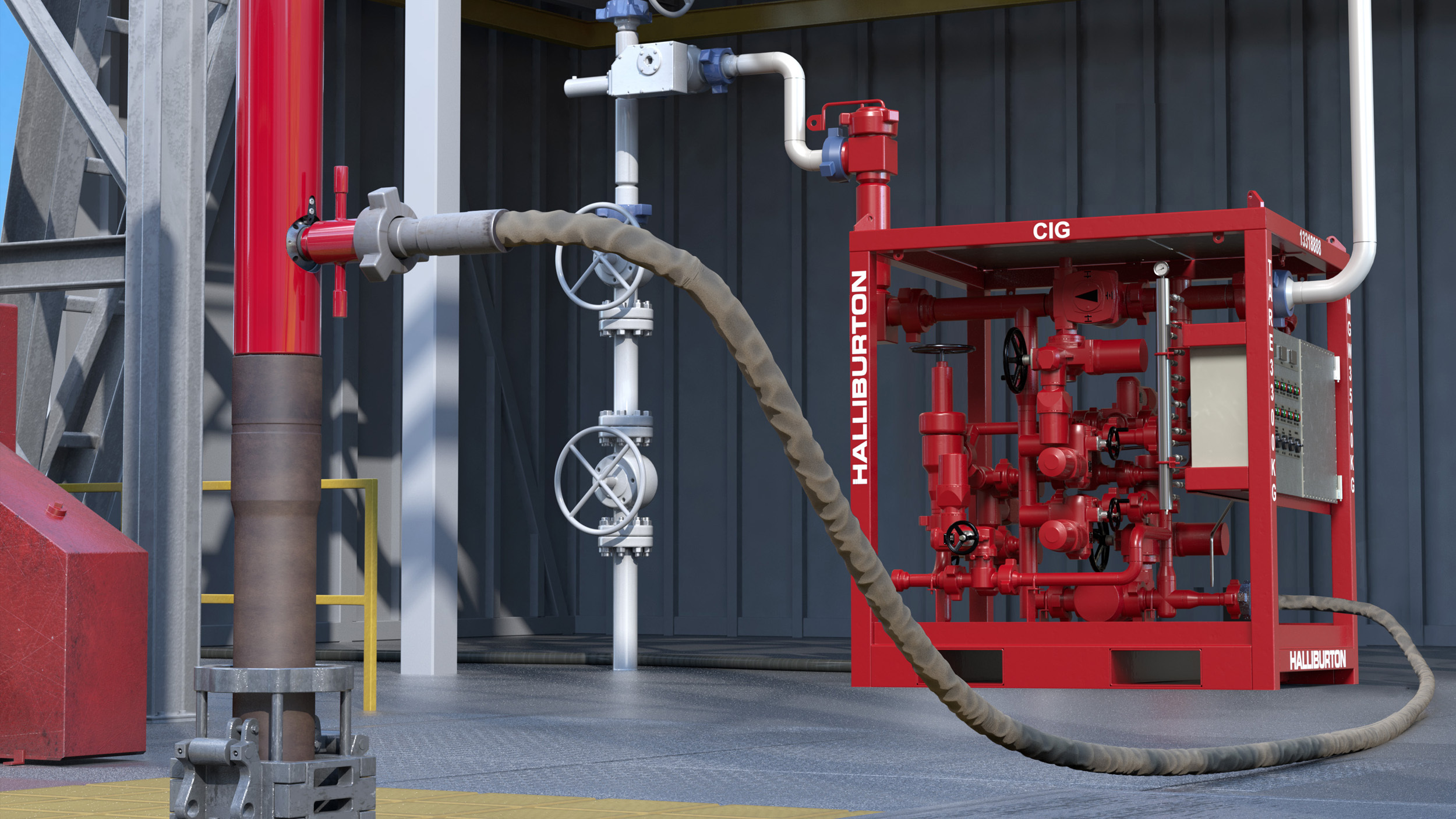

The Halliburton e-cd™ circulating device is an Eni-patented system that enables continuous circulation during managed pressure drilling operations

talk to an expertHalliburton's continuous circulation system (CCS) enables continuous circulation during the drill pipe connection process for drilling and tripping narrow pressure window wells and providing continuous hole cleaning. By maintaining constant circulation of drilling fluid, operators can keep their rig pumps on while adding and removing drillpipe. This unique technology solves many potential problems; in particular, it helps maintain flow through continuous hole cleaning and solids transport.

World Oil / March 2022

This article discusses how continuous circulation technology consistently delivered a decrease in drill pipe connection times while reducing overall risks and operator costs.

See ArticleCASE STUDY / Europe

e-cd™ device maintains uninterrupted fluid flow and improves wellbore stability during drill pipe connections

See Case StudyThe e-cd™ continuous circulation system (CCS) solves the start/stop problem that has persisted since the introduction of conventional rotary drilling. The standard process of pumping drilling fluids into the well is interrupted to turn pumps on and off every time a new joint of drillpipe is added to or removed from the drillstring.

With continuous circulation, there is no interruption to the flow of drilling fluid into the well throughout the process of adding drillpipe joints to—or removing these joints from—the drillstring. This results in improved success rates for challenging projects, including wells with narrow pore pressure/fracture gradients, high-pressure/high temperature (HP/HT) wells, and extended-reach wells.

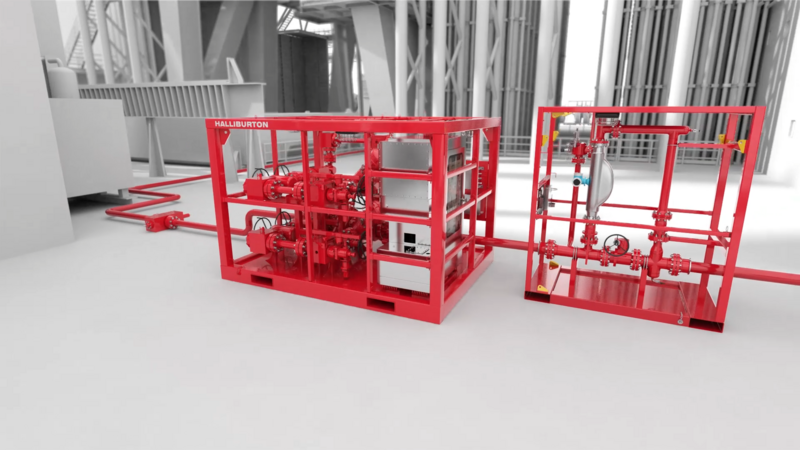

The e-cd™ CCS is engineered for drilling and tripping operations, enabling pumps to continue running while making connections. This keeps bottomhole pressure constant and maintains the same fluid rheology and temperatures, and ensures that cuttings keep moving. The e-cd™ continuous circulation system sets a benchmark for drilling innovation with proven success in efficiency, safety, and costs.

CASE STUDY / SOUTHEAST ASIA

A total of 16 e-cd™ connections were made while running liner through a narrow operational window formation.

See Case StudyCASE STUDY / UAE

Combining the e-cd™ system and MPD enabled the operator to drill to the planned depth, to gather the necessary data in an extreme environment, and to eliminate the need for an additional liner.

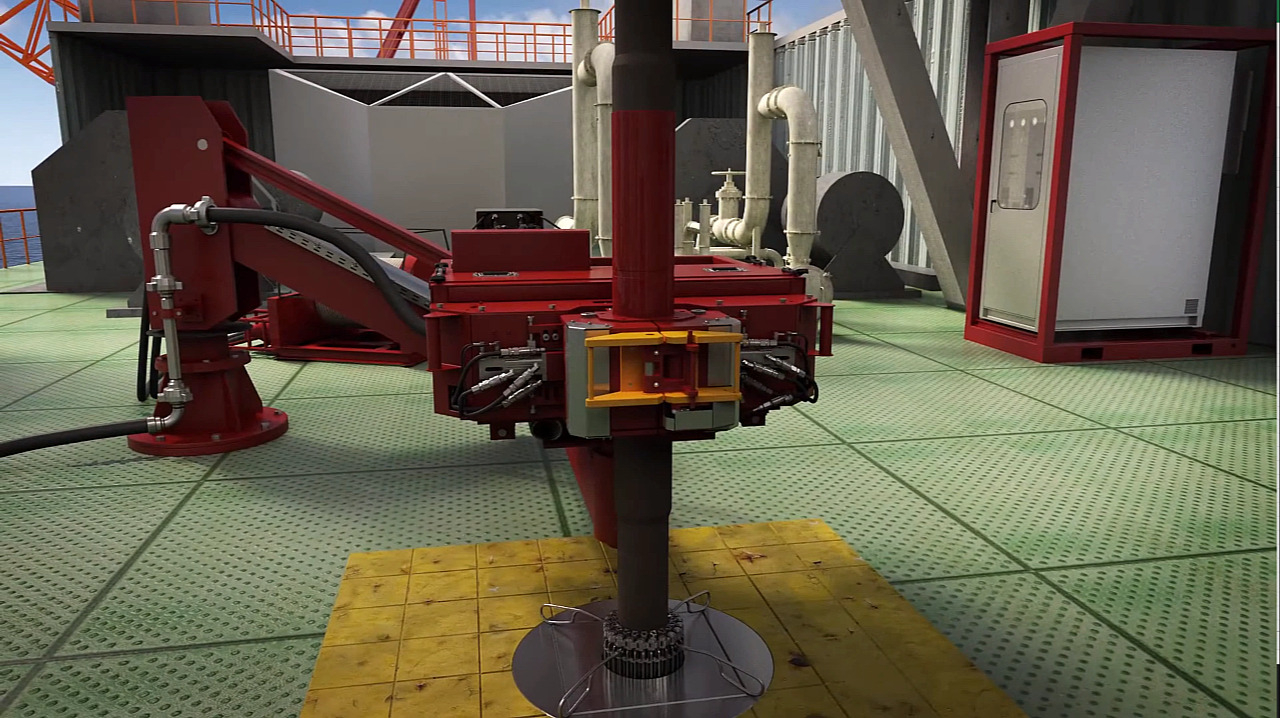

See Case StudyThe e-cd™ system automates the e-cd connection process, utilizing specialized software operated from a remote computer workstation.

02:01

The e-cd™ circulation device improves success for challenging projects such as wells with narrow pore pressure/fracture gradients by keeping bottom hole pressure constant, providing continuous cooling in high-pressure/high temperature (HPHT) wells, and allowing for continuous movement of cuttings in extended reach wells.

Enabling technology that can accomplish efficiency goals while mitigating drilling risks.

A key part of pressure control, Halliburton rotating control devices are the first line of defense against fluid loss during critical operations.

Halliburton's underbalanced drilling service delivers high-performance drilling solutions while focusing on improving reservoir recovery.