Search

Search

Search

Search

A pioneer in underbalanced drilling, Halliburton helps minimize near-wellbore damage, increase well productivity, and accelerate production revenue

talk to an expertHalliburton underbalanced drilling (UBD) services achieve well construction and production objectives in challenging reservoirs. Drilling underbalanced, slightly below reservoir pore pressure, requires both the right equipment and expertise. Our advanced technology, products, and services, combined with real-time reservoir evaluation, focus on improving reservoir understanding and recovery while maximizing asset value.

The UBD project management team works with operators to increase penetration rates, reduce formation damage, mitigate stuck pipe incidents, and lower lost circulation requirements. Halliburton helps turn reservoir challenges into reservoir success.

As an industry leader in underbalanced drilling solutions, Halliburton can help minimize near-wellbore damage, increase the productivity of wells, and accelerate production revenue. Developing and managing the reservoir during the full spectrum of the well construction process is the basis for successful underbalanced drilling programs.

Advantages of underbalanced drilling:

Our well construction and project management skills, reservoir characterization services, and technologies are brought together to deliver an optimal underbalanced program that lowers cost and increases value.

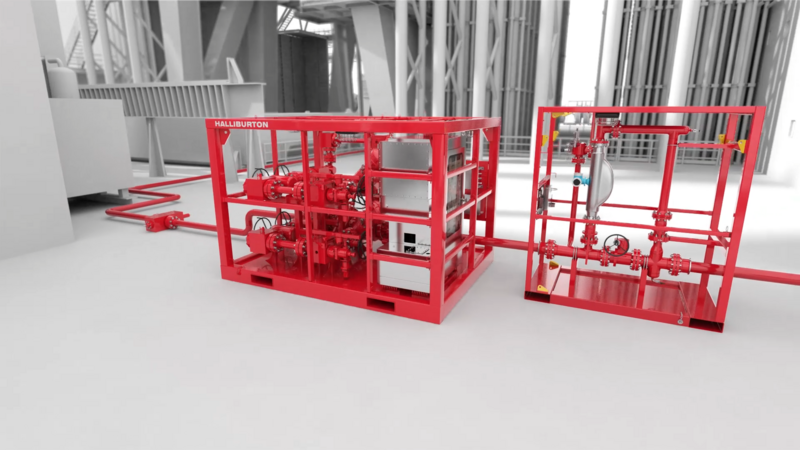

The advanced technology nitrogen membrane generation plant comprises the latest design enhancements in feed air compressors, membrane nitrogen generation, and nitrogen compression. The nitrogen membrane system generates a minimum 95 percent nitrogen purity. The control system continually and rapidly controls purity and monitors all major system parameters. A high accuracy pressure- and temperature-compensated flow meter provides instantaneous and totalized flow to the jobsite data acquisition system. All information is conveniently displayed on a master display panel, indicating all parameter levels and alerting the operator to system alarms and shutdown options.

Enabling technology that can accomplish efficiency goals while mitigating drilling risks.

A key part of pressure control, Halliburton rotating control devices are the first line of defense against fluid loss during critical operations.

The Halliburton e-cd™ circulating device is an Eni-patented system used in managed pressure drilling operations