Search

Search

Search

Search

Transition to remote operations underscores need for robust barrier management

Download PDFTo thrive in today’s economic environment, major oil and gas companies are expecting more automated systems that can consistently accomplish drilling activities with higher speed, increased accuracy, and less human intervention. The automation of barrier management and managed pressure drilling (MPD) operations are a prime example of new technology solutions to meet such demands.

An automated MPD system capable of remote operations requires a robust, redundant, and extremely dependable barrier management system.

What barriers exist, what their critical controls are, and how their status is assessed and monitored in daily operations. Barrier management involves both risk management and mitigation.

This final part of barrier management is where the MPD systems can really shine. With the ability to manipulate the pressures in the well, using SBP, automated MPD systems can actively maintain, and even improve, the barrier’s health as it weakens.

The first challenge with any barrier management system occurs in the planning and design phase, when the barriers and their limits must be clearly identified. While barrier management is by no means a new concept to the industry, the classification of risk and identification of different barriers vary from company to company. For conventional drilling operations, these risks and barriers are well defined and generally well-regulated with documented industry best practices and minimum safety requirements, such as API 6, API 16, API 53, API 59, and API 92M. But with the introduction of new technologies and techniques, like MPD, paired with the industry’s increased push to automation, these existing regulations and best practices can fail to properly identify some of the new risks and barriers.

Enabling technology that can accomplish efficiency goals while mitigating drilling risks.

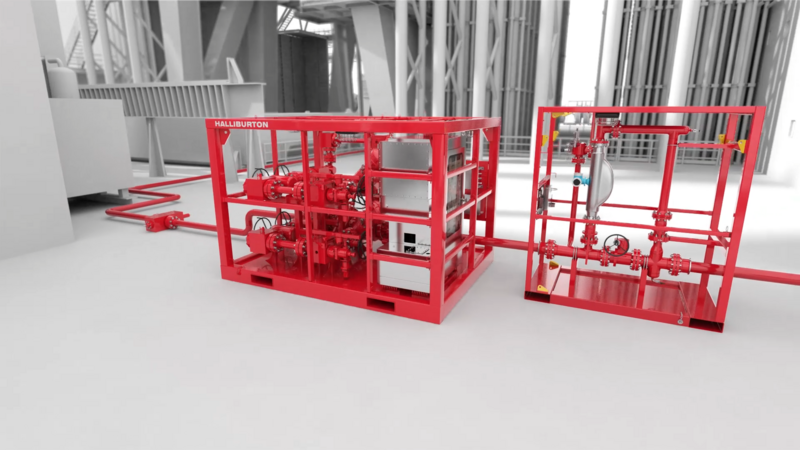

The Halliburton e-cd™ circulating device is an Eni-patented system used in managed pressure drilling operations

Halliburton's underbalanced drilling service delivers high-performance drilling solutions while focusing on improving reservoir recovery.

A key part of pressure control, Halliburton rotating control devices are the first line of defense against fluid loss during critical operations.