Search

Search

Search

Search

VersaFlex® XSL expandable liner hanger system provides a reliable solution in high frac pressure environment

Download PDFDesign a system to accommodate casing change

Powder River basin

An operator in the Powder River basin required a 5.5 x 8.625-inch VersaFlex expandable liner hanger (ELH) to deploy a production liner, as well as provide the ability to tie back casing to surface and withstand 10,000-psi frac pressure. Halliburton delivered a standard VersaFlex XSL ELH system to provide the liner-top seal with a lower polished bore receptacle to enable liner tieback.

The customer originally requested a 7.0 x 8.625-inch ELH system to deploy a drilling liner to cover a challenging zone. The required liner hanger size did not exist in the Halliburton ELH portfolio so the VersaFlex ELH operations and technology groups collaborated to design a system that would meet the customer’s objectives. However, after a change in casing design, the customer wanted to hang a 5.5-inch production liner inside the 8.625-inch intermediate casing. The change to a production liner exposed the liner hanger to high fracturing pressures, not accounted for in the original project design.

In response to the customer’s request, Halliburton proposed an alternate job design that included the VersaFlex XSL ELH system. The Halliburton engineering team worked with the customer to determine the pressures and forces the liner hanger would be exposed to during the fracturing treatment. In addition, because the original liner hanger project did not require a tieback receptacle, multiple tubing movement simulations helped determine the necessary tieback receptacle length. The team ultimately decided to use a lower polished bore receptacle, which is easily adapted to the VersaFlex XSL ELH system.

in. Liner Hanger created

psi frac pressure provided

service quality issues

Halliburton successfully deployed the 5.5 x 8.625-inch VersaFlex XSL ELH, which included the ability to run tieback casing to surface, to fit the customer’s updated casing design. During pre-frac testing, the customer observed damage to the intermediate casing and successfully installed a seal assembly and tieback casing to restore integrity and safely continue operations. Through collaboration and continuous improvement, Halliburton delivered a reliable, engineered liner hanger solution that improved efficiency and maximized asset value.

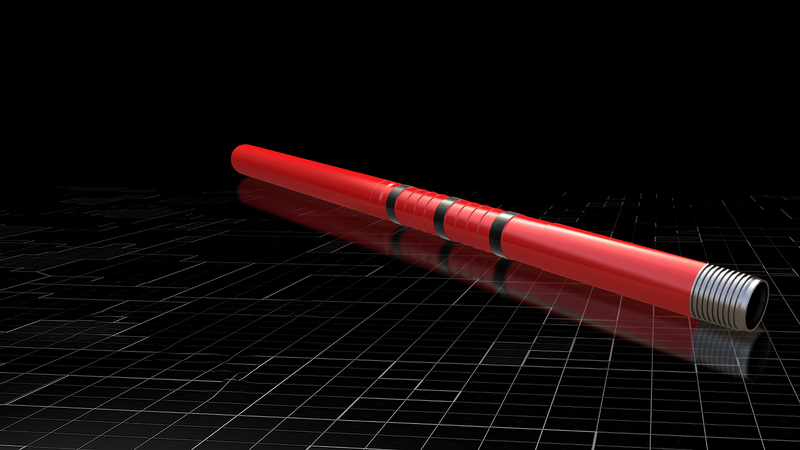

xsl elh system

The VersaFlex XSL expandable liner hanger system delivers low-to-moderate load-bearing without sacrificing its gas-tight sealing capability or reliability

Download Data Sheet

Delivers a low-to-moderate load bearing without sacrificing its gas-tight sealing capability or reliability