Search

Search

Search

Search

Enhanced torque ratings for demanding wellbore envirionments

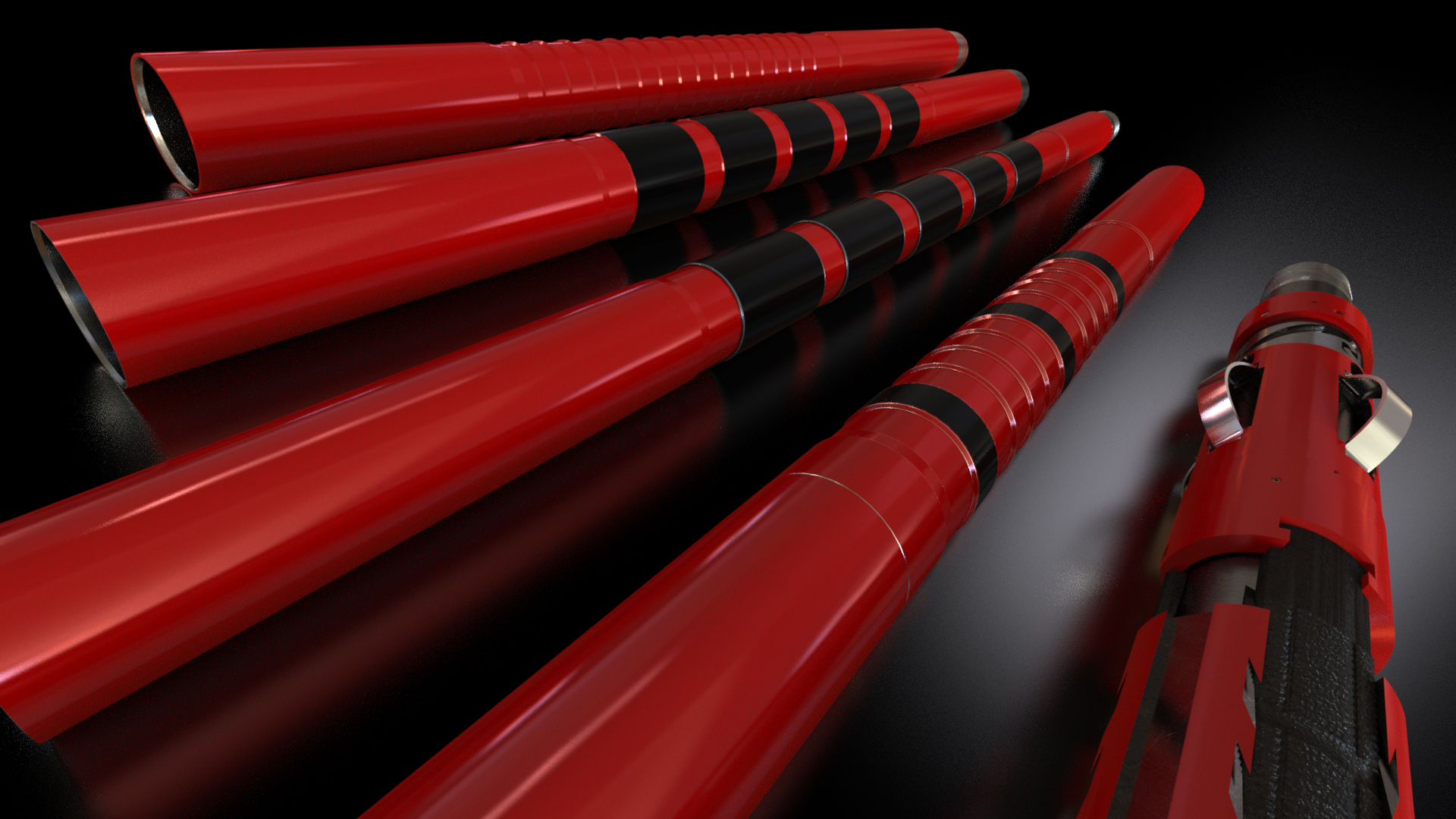

Download PDFDownhole challenges, such as sloughing formations, differential sticking, or complex extended-reach drilling (ERD) environments, require reaming or drill-in with liner capabilities that can handle heavy torque and rotation. With its robust running tool specifically designed for harsh conditions, the Halliburton VersaFlex High-Torque expandable liner hanger (ELH) system provides the ideal solution. Tertiary setting options and mechanical contingency release make this field-proven, high-torque system extremely valuable in demanding wellbore environments.

The VersaFlex High-Torque ELH system includes the rugged high-torque running tool as a companion to our ever-popular and reliable VersaFlex ELH. “Set and forget” sealing capability is made possible by the multiple elastomeric bands, which are hydraulically energized and sealed gas-tight to the parent casing at the liner top. The VersaFlex ELH is secure enough for bi-directional anchoring, which is testable upon setting. Its clean-form design allows a clear flow-path for cementing integrity, unsurpassed by any system in its class.

The VersaFlex ELH high-torque tool is the only liner hanger running tool on the market that offers a tertiary setting mechanism. Primary setting utilizes a flapper deployed upon bumping the plug. A secondary contingency option is to drop a ball allowing it to gravitate to seat or deploy using a timed ball-drop technique, and the third setting option is to mechanically activate the flapper for setting. This tool also offers a mechanical tool release feature that eliminates any contingency shear pin release mechanism, allowing the running tool to be retrieved when needed.

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications