Search

Search

Search

Search

First 16 × 22-in. VersaFlex Big Bore ELH installation for operator in Caribbean

Download PDFDeepwater

Complex geological formations

Caribbean

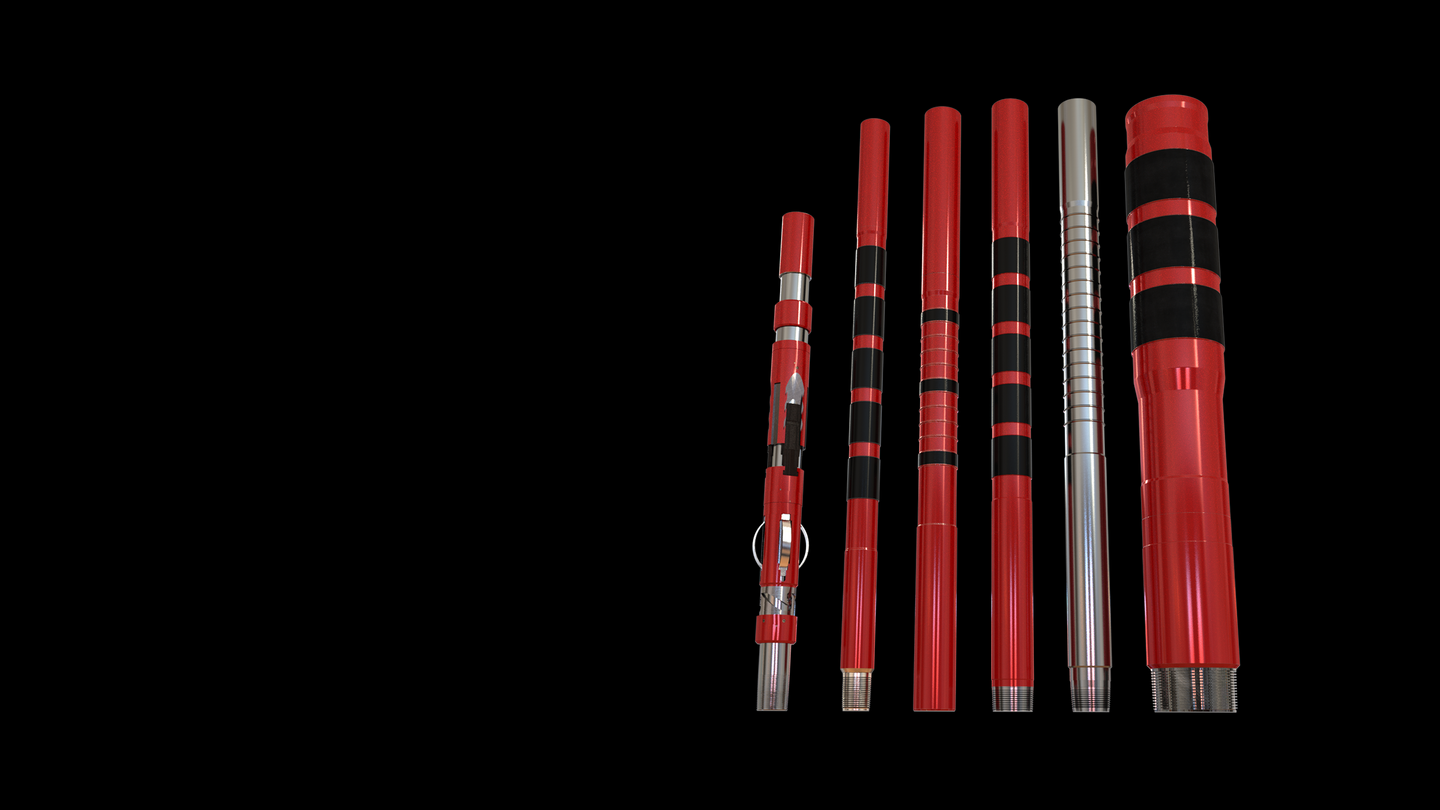

Deploy 16 × 22-in. VersaFlex® Big Bore ELH system for its:

The operator of a deepwater field offshore the Caribbean was challenged with a complex exploratory well design and the potential for over-pressured formations with shallow water flow. Because operations were performed from an expensive deepwater drillship, it was paramount to minimize rig time to reduce operational costs.

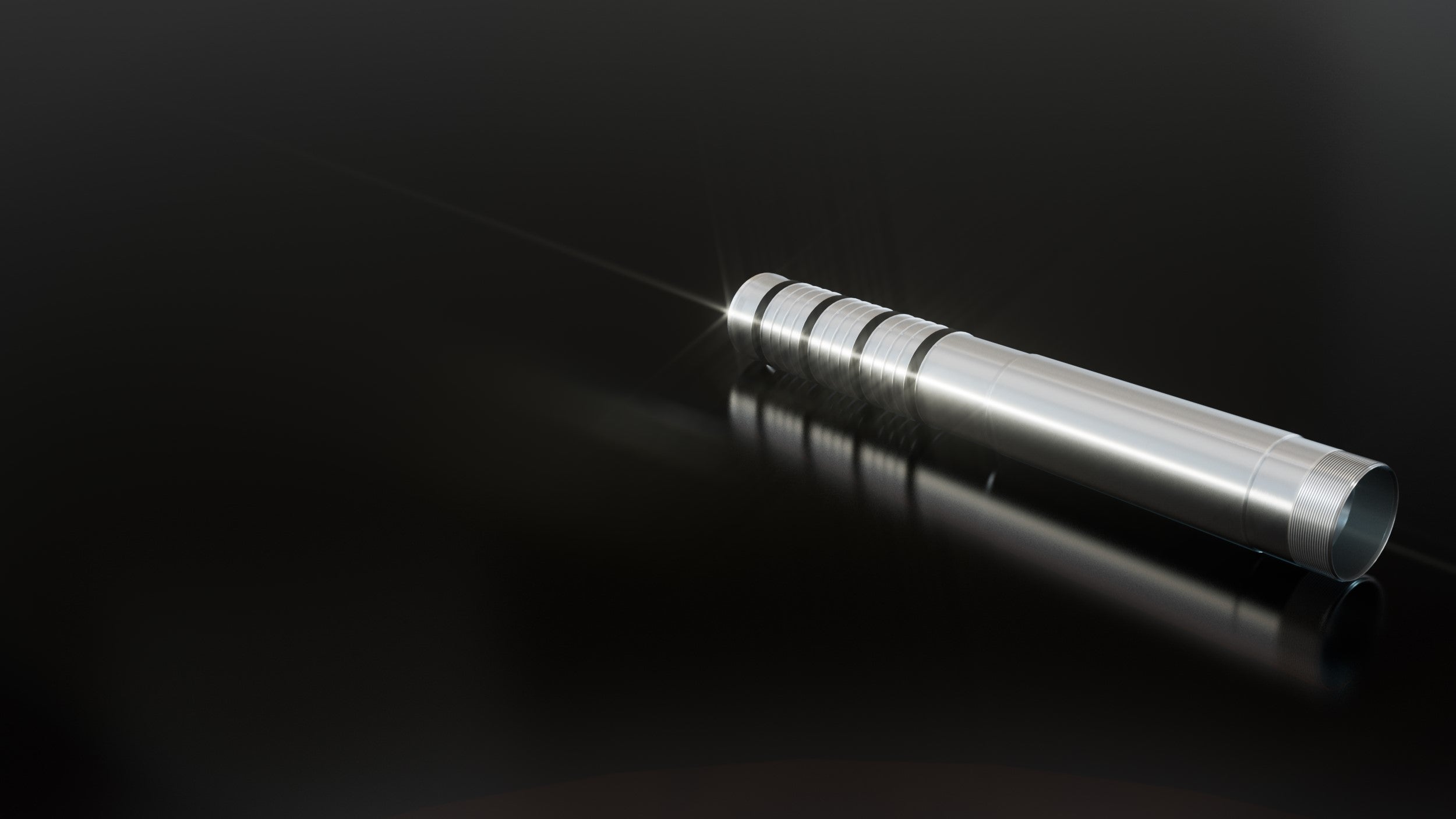

A reliable liner hanger solution was necessary for this deepwater subsea well. The well design involved setting a liner hanger in 22-in. parent casing at an inclination of 28° at the liner hanger setting depth. Operations were planned for 16-in. liner and a contingency 18-in. drilling liner, which ultimately was not installed. Upon flawless installation, a 16 × 22-in. VersaFlex® Big Bore expandable liner hanger (ELH) proved to be a reliable solution. The VersaFlex Big Bore ELH can set in deviated wellbores (28° in this case), while supplemental casing hangers cannot reliably set in deviations more than 2 to 3°.

The potential presence of shallow, over-pressured formations involved a contingency operation that required the 16-in. liner length to be doubled (thus, the overall weight doubled). This situation made it compulsory to provide a robust solution to address probable and contingency scenarios.

Halliburton and the operator worked together during the Basis of Design (BoS) stage to identify a tight ID restriction through which the 16 × 22-in. liner hanger could pass [i.e., the VersaFlex Big Bore liner hanger (18.400-in. maximum OD) needed to pass through the subsea wellhead (18.448-in. minimum ID)].

In addition to the robust liner system and reliable liner-top integrity, the operator required a high-quality cement operation that resulted in an effective formation integrity test and leakoff test. Expedited logistics were also necessary to deliver the components onsite in short notice.

Halliburton recommended the 16 × 22-in. VersaFlex Big Bore ELH system based on its capability to convey the liner string to the established setting depth to allow best-in-class circulation rates. The system is designed to provide independent pressure integrity of the liner top, without sole reliance on cement and to avoid the introduction of potential leak paths common with conventional liner hanger systems. The VersaFlex Big Bore ELH system can pass through even the tightest wellhead restrictions to create a reliable 360° liner top seal with bidirectional anchoring to enable high hang load capacities.

The VersaFlex Big Bore running tool provides immediate confirmation of a successful setting operation, along with the capability for subsequent liner top pressure tests.

16 x 22 in. ELH in Caribbean

objectives achieved

hours of rig time saved

NPT

Halliburton deployed the first 16 × 22-in. VersaFlex Big Bore liner hanger system for this operator in the Caribbean. The liner was run to a measured depth (MD) of 4533 m in one trip. During successful deployment, the 16 × 22-in. Big Bore liner hanger passed through the known and previously identified ID restriction at the subsea wellhead.

Halliburton cemented the liner and isolated the problematic zones. The liner hanger system reduced rig time by 12 hours (in addition to operational costs) through immediate liner-top setting confirmation and subsequent pressure tests, which allowed well construction operations to proceed thereafter.

The VersaFlex Big Bore ELH system was set and the running tool released in less than one hour, which reduced rig time and helped avoid cement remediation operations.

This viable solution was completed within the specified timeline with competent field personnel. The operational success demonstrated the superior performance and reliability of the VersaFlex Big Bore ELH system. The planned ELH installation was performed safely and effectively with distinctive service quality and zero nonproductive time (NPT).