Search

Search

Search

Search

Bara-Hib™ gold trackable inhibitive system delivered excellent wellbore stability in highly reactive clays

Download PDF

Norway

Reduce NAF waste management costs

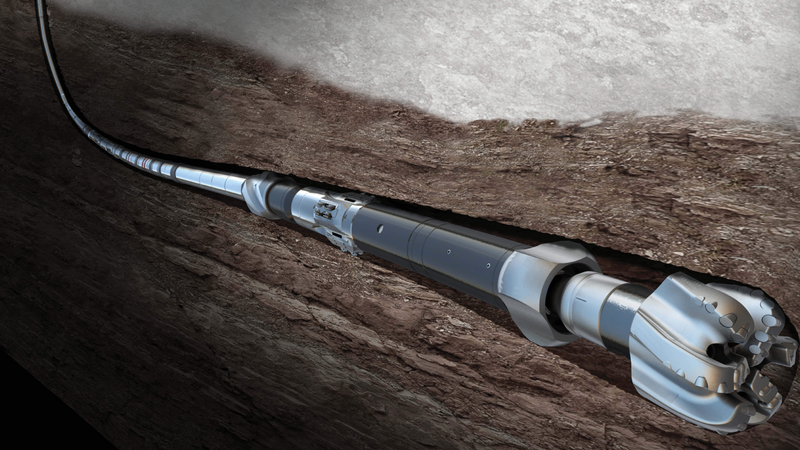

The Pliocene and Upper Miocene shales in a mature Norwegian oil field had not been drilled with water-based mud (WBM) for more than 20 years. Historical offsets noted the abrupt end of use for these fluids after well sections experienced severe shale stability problems. These included gumbo attacks and bit balling, which added time and compromised drilling objectives due to induced losses and poor cement jobs. Sidetracks were commonly needed to reach the reservoir. The overlying Pliocene section is a large diameter interval requiring a fluid density of 10.2 ppg. The underlying 16-in. section requires a density of 12.9 ppg to remain above the collapse gradient as the section builds to an inclination of 50 degrees at target depth (TD).

Although non-aqueous fluid (NAF) systems are well suited for drilling such a highly-technical field, they incur a host of operational expenses for slops and cuttings waste associated with containment, transport, and treatment phases. These ancillary costs have continued to increase in magnitude over time and offset some of the economic gains from added field production, especially in this case since the remote wellhead platform was located away from the main field’s cuttings injection infrastructure. This prompted the operator to trial Halliburton Baroid’s BaraHib® Gold high-performance water-based fluid (HPWBF) in an attempt to reduce their NAF waste management costs.

Shales within these zones are mostly hydratable clays—typically composed of between 30-50% smectite, 10-30% illite, and 10% kaolinite. Cation exchange capacity (CEC) tests indicated results between 5 and 20 meq/100 g, with increasing reactivity with depth (Figure 1). This all meant that a very inhibitive WBM design would be required, and the field maintenance practices during drilling would have to ensure that the levels of key inhibitor components were kept up.

An extensive fluid qualification process was initiated at Baroid’s Tananger Laboratory. A customized BaraHib Gold fluid system was developed for each section and qualified against formation samples obtained from previous activity. Capillary suction time analysis of various KCl brine concentrations aided in determining the optimum salt concentration for the base brine. The BaraSure™ W-674, BaraSure™ W-546, and GEM™ GP package was optimized to give extremely low shale accretion values (less than 1% by weight on the most reactive shales), while shale swelling was controlled at 11% or less.

The final formulations were approved by the customer, and the well was designated a Critical First Well to ensure global focus within the Baroid organization. In addition to the qualification process, BaraSure W-674 concentrations were tracked to control depletion and maintain optimum concentration while drilling. The cuttings (Figure 2) were dry inside and had visible cutting marks on their exterior, demonstrating a high level of ongoing inhibitive performance.

Both sections were drilled uneventfully, in spite of the challenges which were expected and not those which were not anticipated, and the liners were run and cemented without a hitch. As a result of this successful trial, the concept of using HPWBM for remote drill centers was approved, considerably reducing NAF cuttings handling and disposal expenses. The estimated future savings are calculated to be USD 500 K - 1 MM less per well, compared to oil-based mud.

This first-time trial demonstrated to the client that problematic upper sections can be drilled effectively with HPWBM. Two remote wellhead centers will be exploited in the future using the BaraHib Gold solution, with the potential to realize significant savings for the operator of between USD 4 MM and 8 MM for a planned eight-well campaign.

Halliburton leads the drilling fluids industry with cutting-edge solutions, including advanced drilling fluids and solids control technologies.

Measure, test, and treat high-performance additives with the BaraHib system to help maximize wellbore stability by ensuring effective clay inhibition