Search

Search

Search

Search

Survey management MaxBHA™ software performs sag correction and ensure well position accuracy

Download PDFUnconventionals

Avoid potential costly sidetracks for a blowout relief

Southern USA

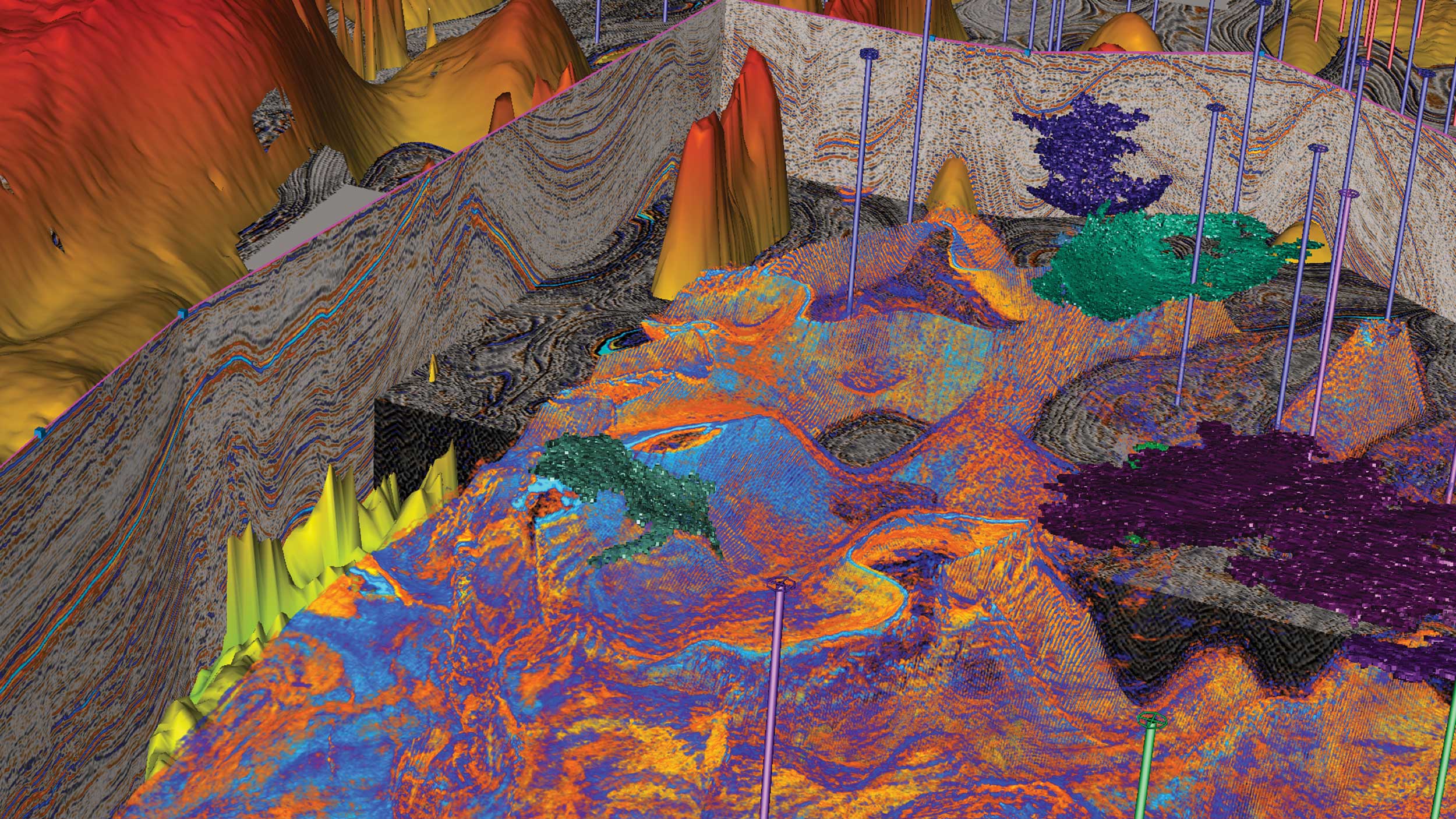

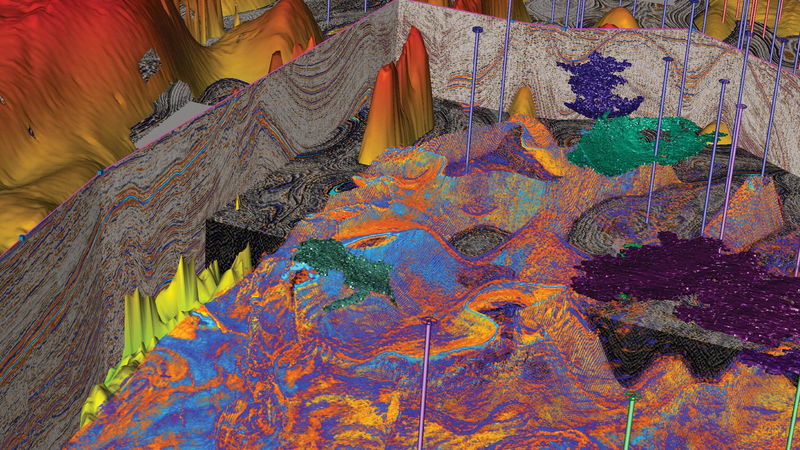

While conducting operations on an unconventional relief well for a blowout in a field in the southern part of the USA, an operator observed a discrepancy in the well position after analyzing the data from two separate surveys in the same wellbore. A relief well was drilled to the first ranging depth, and a wireline gyro survey was run before determining the location from the relief well to the target well (or a ranging determination). During these operations, it was determined that there was a difference between the wireline gyro surveys and measurement-while-drilling (MWD) surveys. The ranging determination supported the wireline gyro surveys rather than the MWD surveys, but there remained uncertainty regarding which surveys were correct.

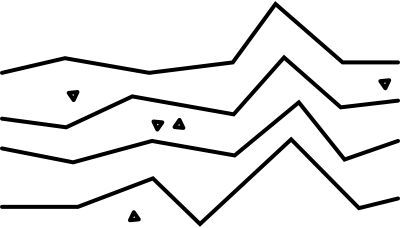

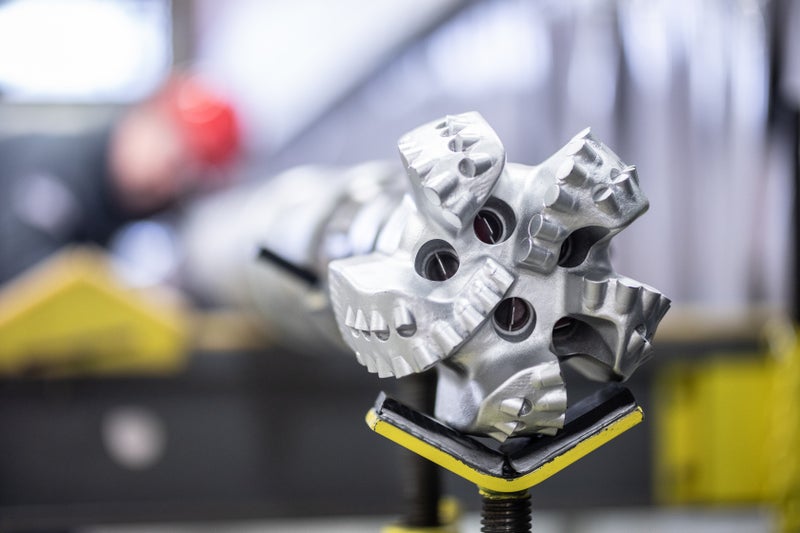

For a blowout relief well operations, it is critical that operators obtain accurate survey data so that the relief well can successfully and efficiently intersect the target well. In this case, the operator observed a separation distance of almost 40 feet (12 meters) between the wireline gyro survey and the MWD survey, with a true vertical depth (TVD) difference of over 8 feet (2.4 meters). Bottomhole assemblies (BHAs) are typically flexible enough to accommodate drilling curves in oil and gas wells. This flexibility, or sag, can lead to errors in inclination measurements when the MWD sensor is not parallel to the wellbore or is not lying flat on the bottom of the wellbore. The operator challenged Sperry Drilling to find a solution to analyze and compensate for this discrepancy so that both surveys would line up accurately and, thus, potentially avoid costly sidetrack operations.

To investigate the discrepancy between the wireline gyro and MWD surveys, Sperry Drilling Survey Management service advised the operator to run the MWD surveys through its MaxSurvey™ software for multi-station analysis, and determined that the difference was not caused by an error in the MWD azimuths, but rather by sag in the MWD inclinations. Using MaxBHA software, the survey management experts were able to model the BHA’s sag misalignment error and apply a corrected inclination, thus representing the MWD sensor as if it were parallel to the wellbore and delivering a more accurate well position. Performing sag corrections on the survey data enables the use of sag corrected coefficients in the instrument performance model (IPM), which reduces the ellipse of uncertainty, particularly TVD uncertainty around the wellbore.

The BHA is flexible, and when the BHA is not stabilized to house the MWD sensor parallel to the wellbore, a sag misalignment can occur that leads to an error in the inclination measurement. In other applications, utilizing IPM containing sag-corrected coefficients reduces the TVD error ellipses uncertainty and helps enable better reservoir drainage and TVD control for staying in the targeted formation zone.

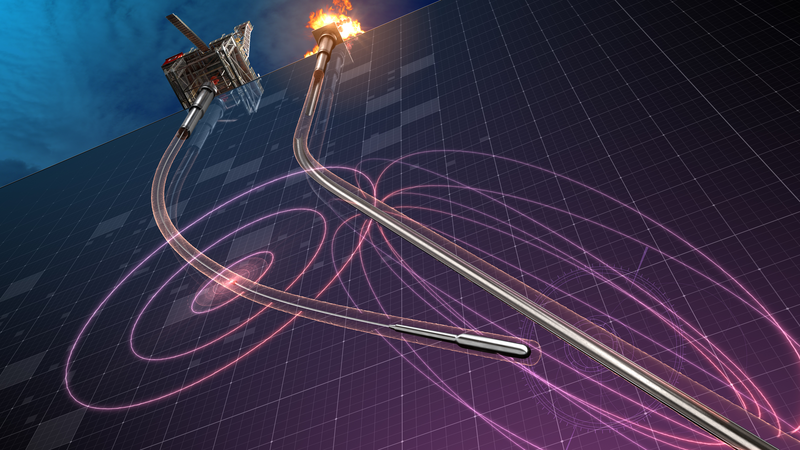

In addition, the Sperry Drilling WellSpot™ Ranging service utilized active ranging technology to magnetically excite the target well in order to efficiently locate, follow, and intercept the well.

Reduction in TVD

Reduction in Separation

Using real-time sag-corrected inclination measurements, Sperry Drilling enhanced reservoir understanding and well positioning by helping the operator correct the inclination by -0.3° on average, drastically reducing the separation distance and TVD uncertainties by 84 percent of separation distance and by 78 percent of TVD separation, thus improving the accuracy of the overall well positioning. The operator applied sag corrections to the surveys throughout the remainder of the well. Through reservoir insight, Sperry Drilling engineered a drilling solution to reduce uncertainty in well placement and well positioning. By utilizing sag correction along with the WellSpot Ranging service the operator was able to intersect and stop, or kill, the blowout well, more efficiently, avoiding additional rig time, and maximized asset value.

Halliburton delivers drilling performance to increase asset recovery, improve wellbore quality, and reduce overall well construction costs.

Using advanced real-time software to increase survey accuracy and reduce positional uncertainty.

WellSpot™ active magnetic-ranging systems use precise sensors to provide data for multiple drilling applications.