Search

Search

Search

Search

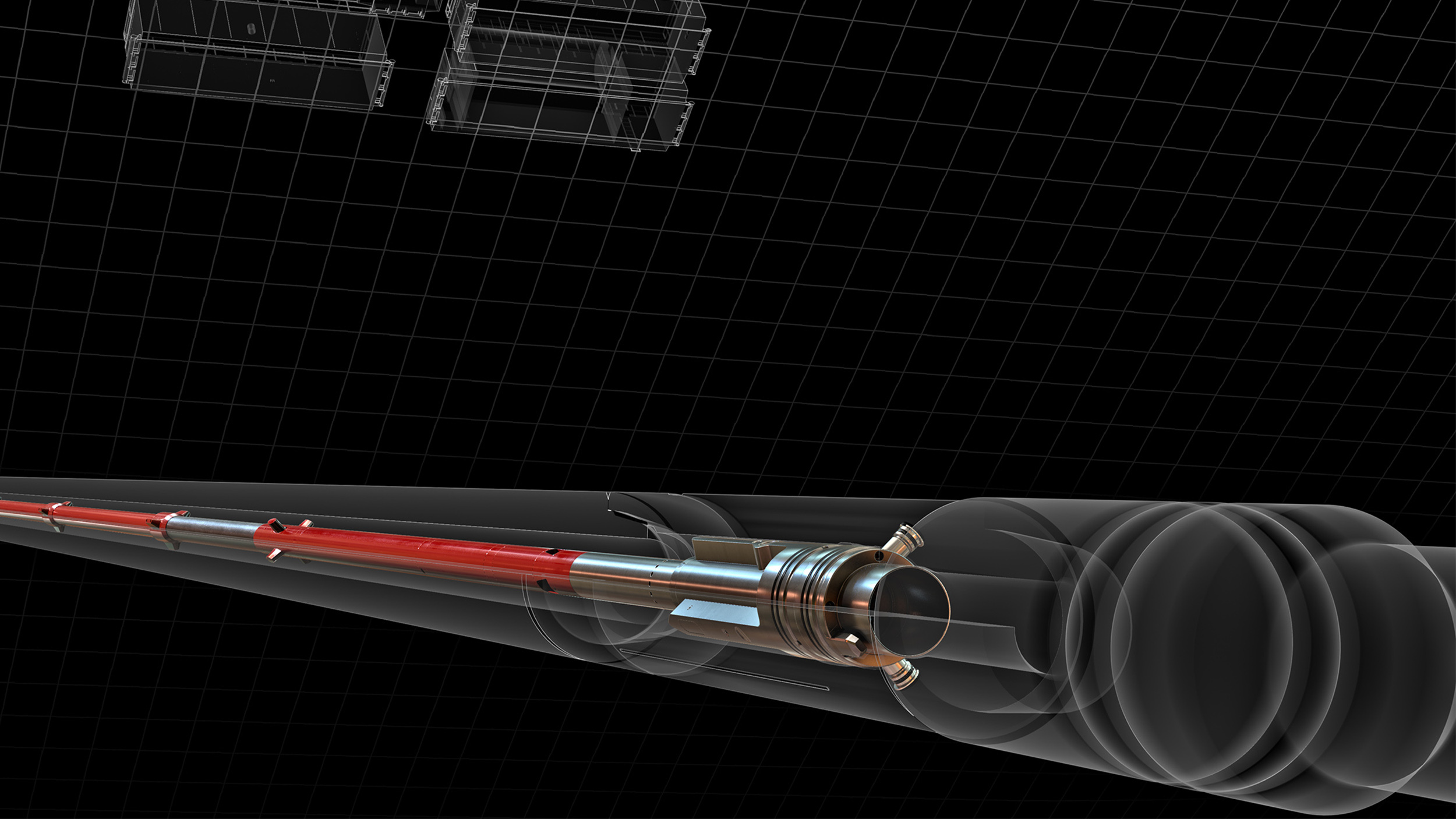

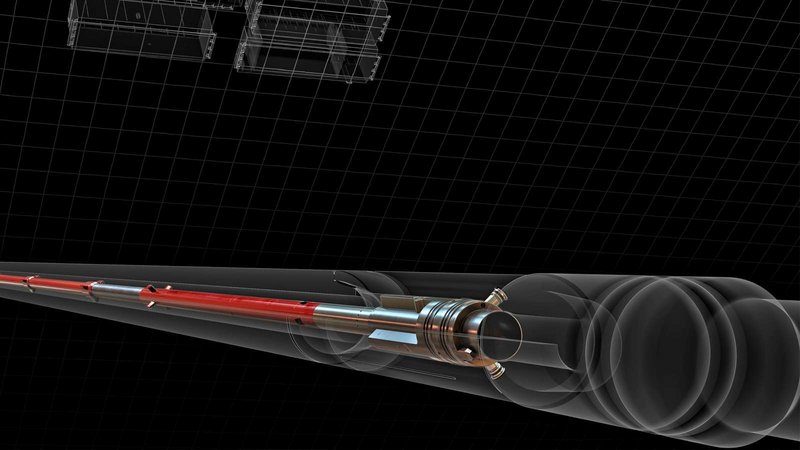

QuickPulse™ automated directional gamma service reduces well time over multiple lateral sections

Download PDFUnconventionals

Use automated directional gamma service to overcome well construction challenges

Bakken Formation, Mountrail County, North Dakota

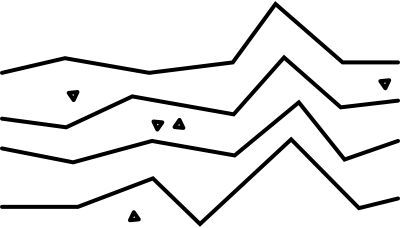

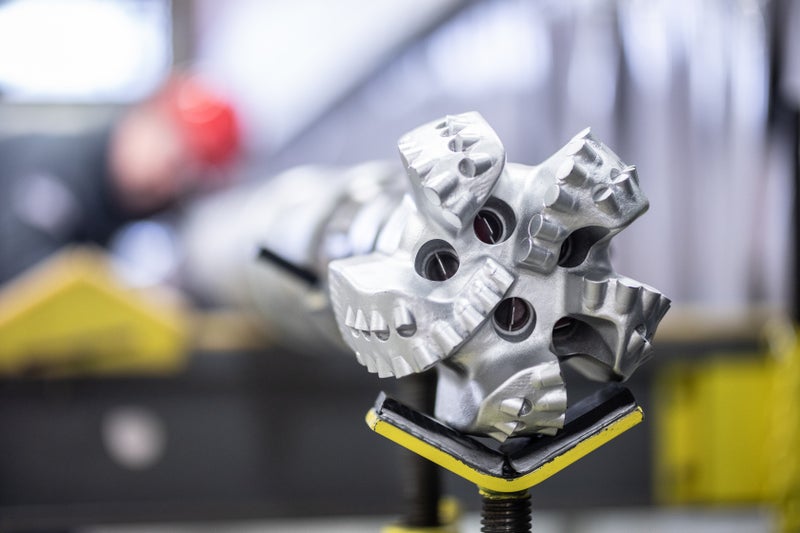

An operator in the Bakken needed to overcome low toolface updates and insufficient gamma data density during well construction. Low frequency updates slowed down operations, particularly toward the end of the lateral sections. Halliburton Sperry Drilling recommended its new QuickPulse™ automated directional gamma service to deliver quick and reliable downhole information and bring lateral well sections over multiple wells to production faster. The automated detection algorithm combined with average data rates of two bits-per-second increased the frequency of downhole data updates, achieving 99% detection efficiency in the curve and lateral sections. Toolface periodicity improved from an average of 24 seconds to 4.5 seconds – 81% improvement over previous systems. Gamma ray density increased from 1.8 sample/ft. to 4 sample/ft. in the intermediate, and 2 sample/ft. in the lateral, helping to place the well accurately and improve steering. Utilizing the unique Halliburton landing sub removed the need to re-orient the assembly between runs or sections, further increasing drilling efficiency. By addressing the data density challenge, the QuickPulse service helped the operator reduce well cycle time, maximizing asset value.

detection efficiency

improvement in toolface periodicity

gamma ray density increase (sample/ft.)

Halliburton delivers drilling performance to increase asset recovery, improve wellbore quality, and reduce overall well construction costs.

Halliburton QuickPulse system delivers quick and reliable downhole data to help you drill laterals longer, faster, and more efficiently.