Search

Search

Search

Search

FloRite® TAML 5 multi-string multilateral completion system eliminates gas ingress

Download PDFMature Fields

Cap gas migrating into wellbore, altering well performance

Middle East

Cap gas was migrating along the cemented liner and into the wellbore via the junction, adversely altering production and well performance

Retrofit the TAML 4 well with a FloRite TAML 5 multilateral completion system to isolate the junction using the completion string

Numerous offshore oil producer wells in the Middle East are drilled as dual laterals to maximize reservoir exposure and deliver the lowest possible cost per barrel of oil equivalent (BOE). Many of these TAML 4 (cemented junction) dual-lateral wells incorporate intelligent completions to independently control and monitor each zone. Halliburton has constructed hundreds of dual-lateral wells using this method. The selected well to trial this retrofit was completed as a dual-lateral well with a TAML 4 cemented junction in 2009. In 2017, the well was worked over and converted to a FloRite TAML 5 multi-string multilateral completion system.

Cap gas migration was observed along the cemented lateral liner and into the wellbore via the junction, where the cement was poorly bonded. Gas influx into the wellbore can increase the gas/oil ratio to preferentially produce gas instead of oil, thereby adversely impacting production and well performance.

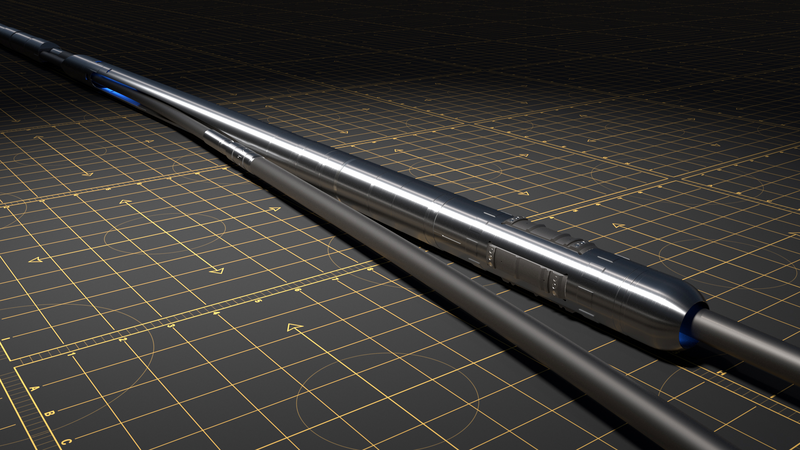

The TAML 4 cemented junction was retrofit with a FloRite TAML 5 multilateral completion system to isolate the junction and halt gas migration to the production zone. The FloRite system is specifically designed for wells that require full junction pressure isolation, while allowing mechanical, selective lateral intervention through the completion during the life of the well. FloRite systems achieve junction isolation by way of two multilateral completion components, conventional packers, and seal assemblies that provide pressure integrity across the junction through the completion.

Success Rate

Level 5 Installations

Once the well was successfully decompleted, the original Latch Coupling anchor installed in the 9 5/8-inch casing string provided the foundation for the recompletion of the lateral and junction. The workover was completed as planned, pressure isolation was achieved at the junction, and gas ingress into the oil-producing lateral was eliminated. Access to both laterals was also retained, allowing future intervention operations. The successful workover restored well productivity and therefore extended the production life of this mature well

FloRite Multilateral Completion System

The FloRite multilateral completion system provides TAML Level 5 junction pressure integrity and re-entry capability without pulling the upper completion.