Search

Search

Search

Search

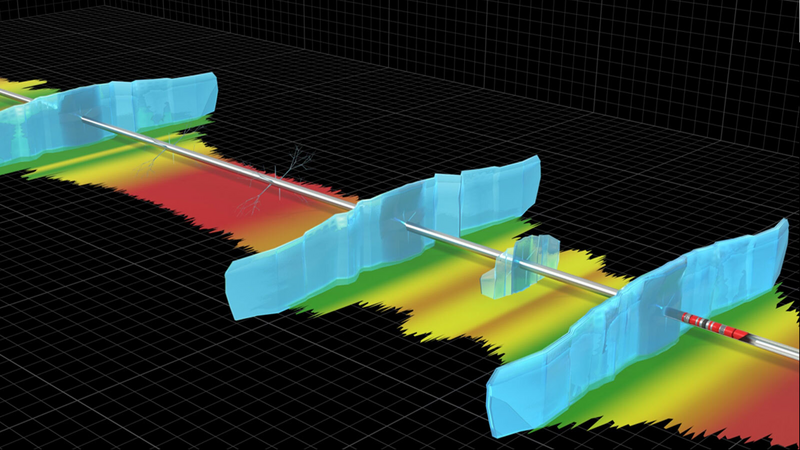

The RMT-3D™ pulsed-neutron tool accurately monitors reservoir water, oil, and CO2 volumes

Download PDFMature Fields

Help Kinder Morgan maximize production in an enhanced oil recovery (EOR) project

Permian Basin, West Texas

The Kinder Morgan Scurry Area Canyon Reef Operators Committee (SACROC) field is a mature Permian-age carbonate reservoir in West Texas with a complex fracture network of limestone and dolomite vugs. SACROC was under waterflooding for many years before being switched to a CO₂-type enhanced oil recovery (EOR) project. This is also described as a miscible flood, which mixes with the residual oil, allowing for increased oil production and recovery. The original oil in place (OOIP) of SACROC was estimated at approximately 2.8-billion barrels of oil and cumulative production of 1.2 billion barrels. Daily production from CO₂ flooding is about 30,000 BPPD of oil.

Originally, the SACROC field was estimated to have 90% oil saturation. Conventional infill drilling and production brought the oil saturation down to roughly 60%. Maximum waterflooding recovery methods can bring this down to an estimated 30% oil saturation under ideal conditions. EOR methods, such as CO₂, can ultimately bring the oil saturation down to below 20%.

The field consists of 3 types of wells—CO₂ injection wells, dedicated monitor wells, and production wells. Logging injection wells over time can cast light on which zones are taking the most super-critical CO₂. Logging the dedicated monitor wells over time can give an indication of the sweep efficiency of the CO₂ flood and how it is progressing through the reservoir.

The CO₂ flood sweep efficiency is affected by changes in porosity, horizontal and vertical permeability changes, the fracture network, as well as other heterogeneity factors. Logging the production wells over time shows the changes in the reservoir, production efficiency, and rates at which the zones are changing relative to water, oil, and CO₂. This information will also clarify overall sweep efficiencies and inefficiencies that may be addressed.

Knowledge of which zones the injected CO₂ is flowing through and the residual oil saturations allows the operator to tailor the CO₂ flood. Maximizing recovery, even by a few percentage points, of the remaining 1.6 billion barrels can greatly improve the return on investment.

CO₂ saturation would historically be calculated using pulsed-neutron sigma decay methods, but with mixed and unknown salinity due to a history of flooding operations, sigma-based saturations have high uncertainties so another measurement and method must be used. Also, the oil saturation from a traditional carbon-oxygen log would also be affected by the miscible CO₂ in the oil phase. In addition, porosity is a key component to all saturation and volume calculations. Measuring the increased porosity from the recent acid treatments must be done in order to calculate accurate saturations.

The Reservoir Monitor Tool 3-Detector (RMT-3D™) pulsed-neutron tool solves for water, oil, and CO₂ saturations in the reservoir using three independent measurements (sigma, carbon-oxygen, and SATG). Carbon-oxygen elemental yields-based saturation calculations are used to determine the saturation and volumes of water and oil in the formation. Carbon-oxygen is independent of formation water salinity, but must be corrected for the presence of gas or CO₂. Sigma-based measurements can be used to determine gas or CO₂ volumes and saturations, but rely on accurate knowledge of formation water salinity. In reservoirs where the formation water salinity is low, mixed, or unknown, sigma-based measurements have high uncertainty.

Our new SATG ratio gas saturation measurement has both reduced salinity and reduced lithology dependency. This allows for accurate CO₂ saturation calculations and gives us the CO₂ volume needed to correct carbon-oxygen results. In addition, porosities can be calculated using pulsed-neutron-based inelastic and capture ratios, which are similar to openhole neutron and density porosity measurements.

independent measurements

phase fluids

trip in the hole

This logging program provided the necessary insight about what was occurring downhole to make decisions for the project moving forward. Kinder Morgan has been able to reduce cost and risk while also improving production and recovery by switching to the cased-hole RMT-3D pulsed-neutron logs for both new and existing wells in some areas. For new wells, traditional openhole wireline logs were used that increased drilling-rig time and costs. The RMT-3D tool can be deployed after the casing has been set and the rig moved off location, thus saving rig time. On existing cased-hole wells, the RMT-3D tool is able to solve for porosity, water, oil, and CO₂ saturations using three independent measurements (sigma, carbon-oxygen, and SATG). Monitoring injection wells, dedicated monitor wells, and production wells over time has enabled Kinder Morgan to maximize the sweep efficiency of the CO₂ EOR project by increasing oil production and recovery.

For further information, a similar case study is investigated in SPWLA paper, PNL Application in CO₂ and Oil Saturation in CO₂ Flooding Fields.

The Reservoir Monitor Tool 3-Detector™ (RMT-3D™) pulsed-neutron tool solves monitors reservoirs to increase production, improve recovery, and find bypassed pay.

Halliburton formation evaluation services enhance reservoir understanding through our technology and subsurface characteristics for resource development.