Search

Search

Search

Search

Safe, efficient operations collected the required data in 17 days across two wellbores

Download PDFDeep Water

Collect high-quality formation evaluation for an operator's exploratory well

Wilcox Formation, Deepwater Gulf of Mexico, USA

The Halliburton Gulf of Mexico openhole wireline team recently completed logging a customer’s deepwater exploration well. The complex project, located in the Wilcox formation in the Perdido Corridor, was evaluated using the latest Halliburton DeepSuite technology for formation evaluation, along with the Reservoir Description Tool (RDT™) and Rotary Sidewall Coring Tool, among others. Halliburton performed all wireline operations safely and efficiently, collecting all the required data in 17 days between two wellbores. Post-wireline operations, more than 400 feet of additional net pay was discovered.

The customer needed to obtain high-quality formation evaluation, rotary cores, pressures, and fluid samples in two large open holes. The requirements included performing reservoir characterization and rock evaluation for whole-core calibration, and collecting lab-quality samples and accurate reservoir pressures for reservoir quality and structure. Time constraints would need to be optimized for efficient coring operations, while conveying wireline in a highly challenging wellbore trajectory in the sidetrack.

Halliburton recommended a DeepSuite™ reservoir characterization package, including the Compensated Spectral Natural Gamma Ray (CSNG™), GEM™ tool, Dual-Spaced Neutron (DSN™) tool, Spectral Density Logging (SDL™) tool, Xaminer® Array Sonic Tool (XAST™), Xaminer® Multicomponent Induction (MCI) tool services, as well as its latest technologies, the Xaminer® Magnetic Resonance (XMR™), and StrataXaminer™ Borehole Imager services. This in-depth formation evaluation suite provided the client with valuable information about the reservoir, including porosity, fluid mobility, grain density, clay type, rock mechanics, Rv/Rh, and structural dip.

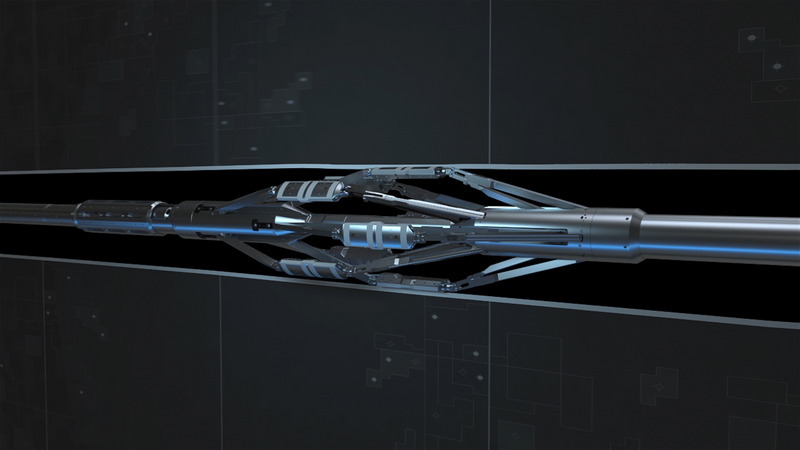

The Rotary Sidewall Coring Tool safely and efficiently collected required cores. The RDT service, including FLID™ and ICE Core® technology, was proposed for its flexible and combinable probe configurations to accomplish all of the required pressure testing, sampling, and fluid analysis in the same run.

A Super Combo Unit (SCU) with industry-leading 18,000-lb Powered Capstan, 40,000-lb PowerPull cable, Releasable Wireline Cable Head (RWCH), and LockJar® technology would be employed for successful wireline conveyance in both wellbores. Toolpusher™ conveyance, using flawless downhole technology, would also assist on the job.

feet of additional net pay discovered

of cores recovered in 24 hours

cores recovered per hour

lab-quality fluid samples

This reservoir lies below 8,000-plus feet of salt and over 6,000 feet of water. With the safest, most capable conveyance system in the industry, Halliburton was able to safely deploy the different tool combinations in one descent, obtaining high-quality sonic, image, porosity, elemental, and magnetic resonance in both large wellbores.

The Xaminer Rotary Sidewall Coring Tool recovered 52 out of 57 cores in 24 hours of coring operations. Averaging 2.4 cores per hour, all of the cores cut and recovered met the customer’s critical success factors.

The RDT service performed over 180 total tests and captured 42 lab-quality fluid samples in 36 x 1000 cc and 6 x 1 gallon chambers in real time, using the EPS, E-FSS, DPS, and D-FSS probes in three successful runs. The versatility of the EPS probe added value to the program with the low-storage volume and flexibility of the tool providing seamless testing and sampling operations. The reservoir engineer was very complimentary of the tool’s performance delivering high-quality, low-contamination samples.

Total operating time for this project was 17 days (409.5 hours) of logging, executed in 10 descents across the two wellbores. Following wireline operations, the client announced a discovery of over 400 feet of additional net pay.

Examine the smallest pores and characterize formations using high-resolution, best-in-class magnetic resonance logging.

StrataXaminer™ provides more accurate well data to better evaluate production potential and increase return on investment.