Search

Search

Search

Search

Operator reduced on-bottom drilling time by 28% and reached TD in one run

Download PDFUnconventional

Drill to total depth in a single run to minimize drilling time

Williston Basin

An operator drilling in the Three Forks formation of the Williston Basin tasked Halliburton to optimize drilling the lateral interval. The Three Forks formation presented challenges due to interbedded hard stringers of carbonate and occasional pyrite. The primary objective was to achieve total depth (TD) in a single run to minimize drilling time. Initially, the operator used a Halliburton drill bit with round cutter technology and competitor six-blade designs. Although this approach completed the interval in one run, further improvements were sought.

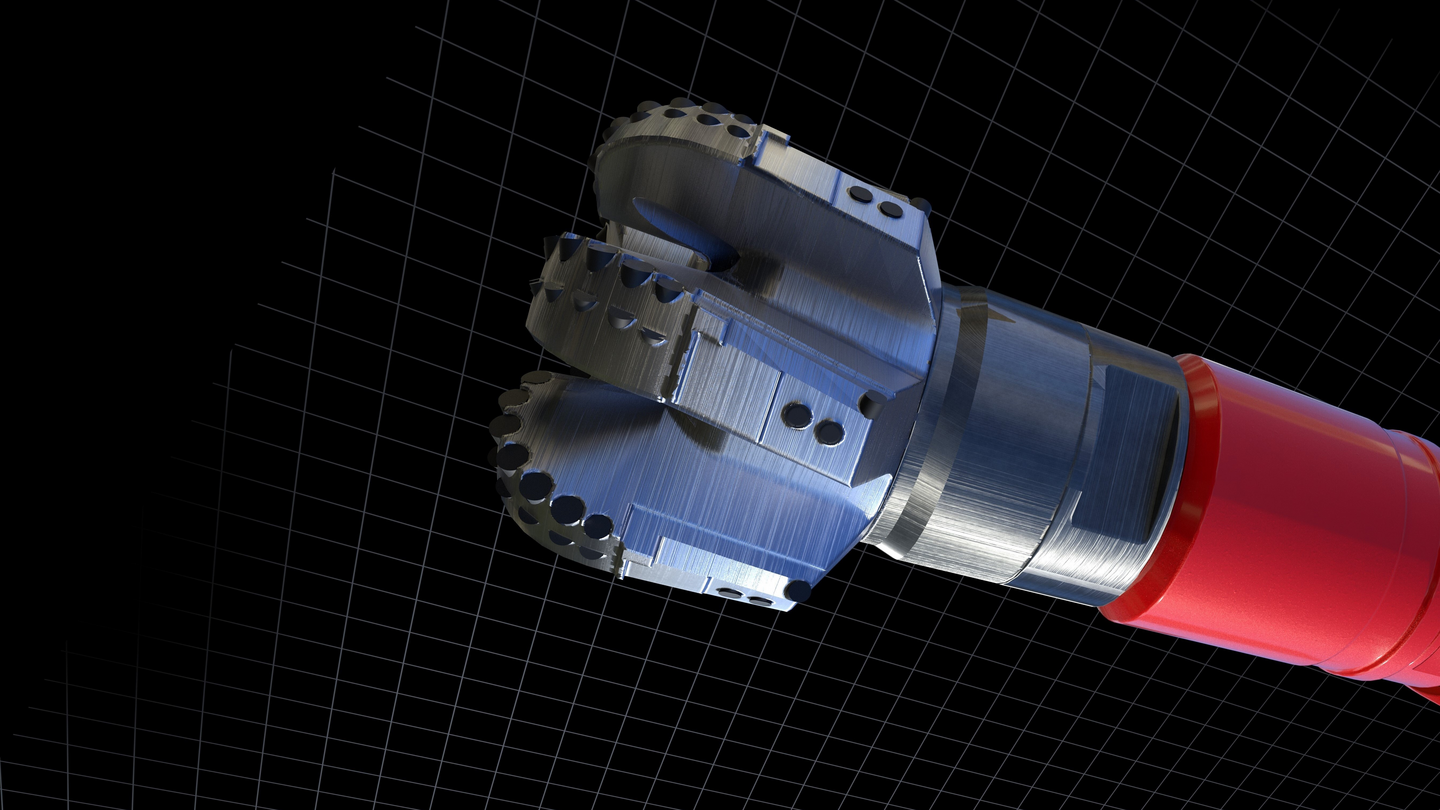

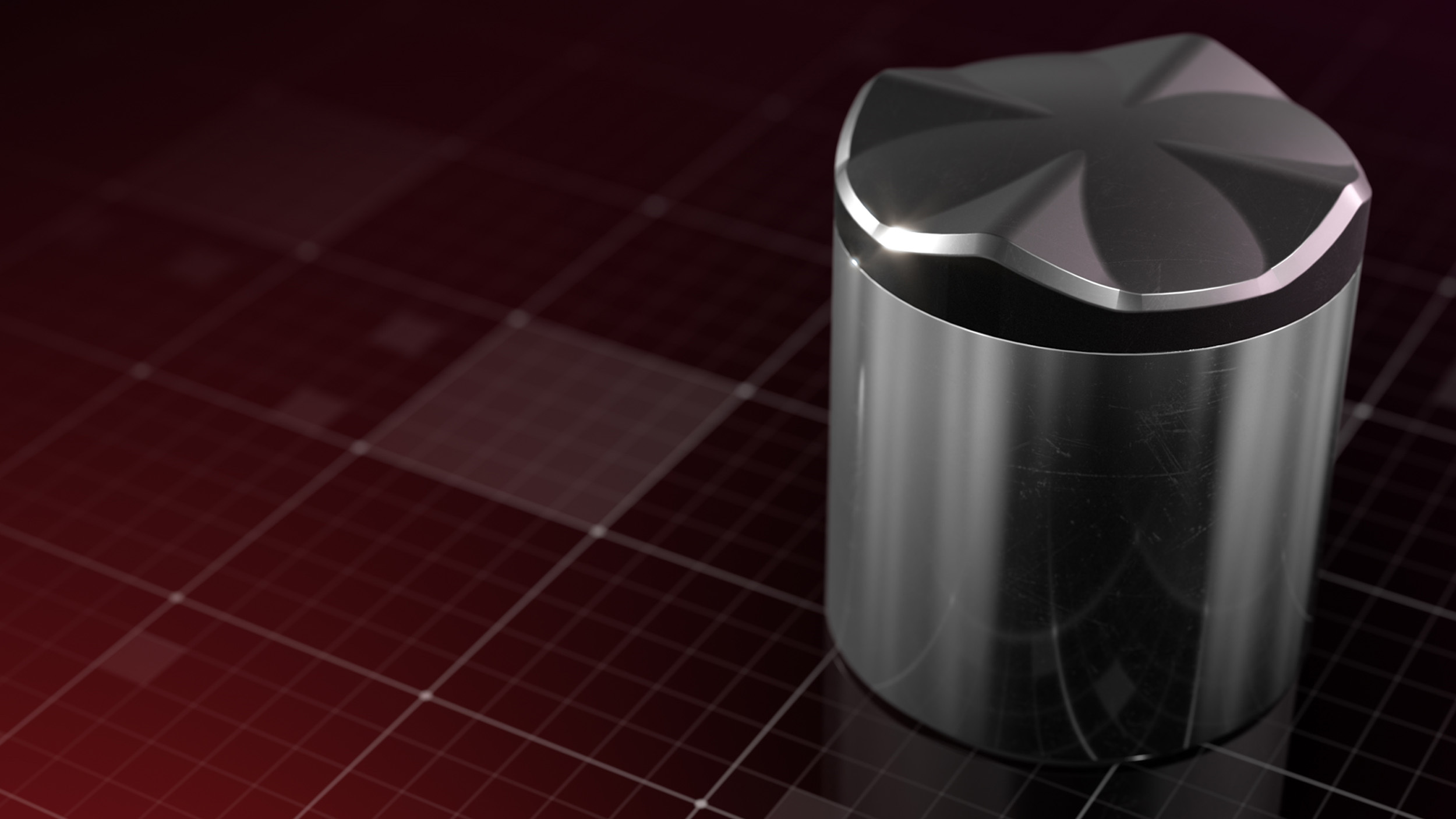

Halliburton introduced the Razor™ 4D-shaped cutters to enhance bit durability and maintain sharpness, ultimately to reduce drilling time. These cutters feature unique geometries compared to traditional cylinder cutters, which result in more efficient drilling. The Razor cutter design effectively engages with rock to maximize contact stress along the cutter-rock interface. It features an enhanced edge profile for improved cuttings removal and evacuation and a durable domed center.

The Razor cutter technology significantly reduced on-bottom drilling time by 28%. The operator consistently reached TD in one run, which exceeded expectations. The durability and productivity advantages of Razor 4D-shaped cutter technology contributed to overall drilling performance improvements.

Geometrix™ 4D-shaped cutters use different geometries to optimize drilling efficiency and durability.