Search

Search

Search

Search

Electrical integrity is maintained in 16,000 SCF/BBL gas-to-oil ratio environment

Download PDFMature Fields

Install a better gas handling ESP system to maintain electrical integrity

The Montney Formation, Alberta, Canada

The Montney formation in Northwest Alberta has gas-to-oil ratios (GOR) in the range of 5,000 –17,000 SCF/BBL. Electrical submersible pump (ESP) systems produce wells at maximum drawdown, achieving greater production than gas lift.

In horizontal wells in the Montney formation, gas rate fluctuations cause fluid density changes at the pump intake. These changes cause electrical stress on the motor and motor lead extension (MLE), shortening pump run life.

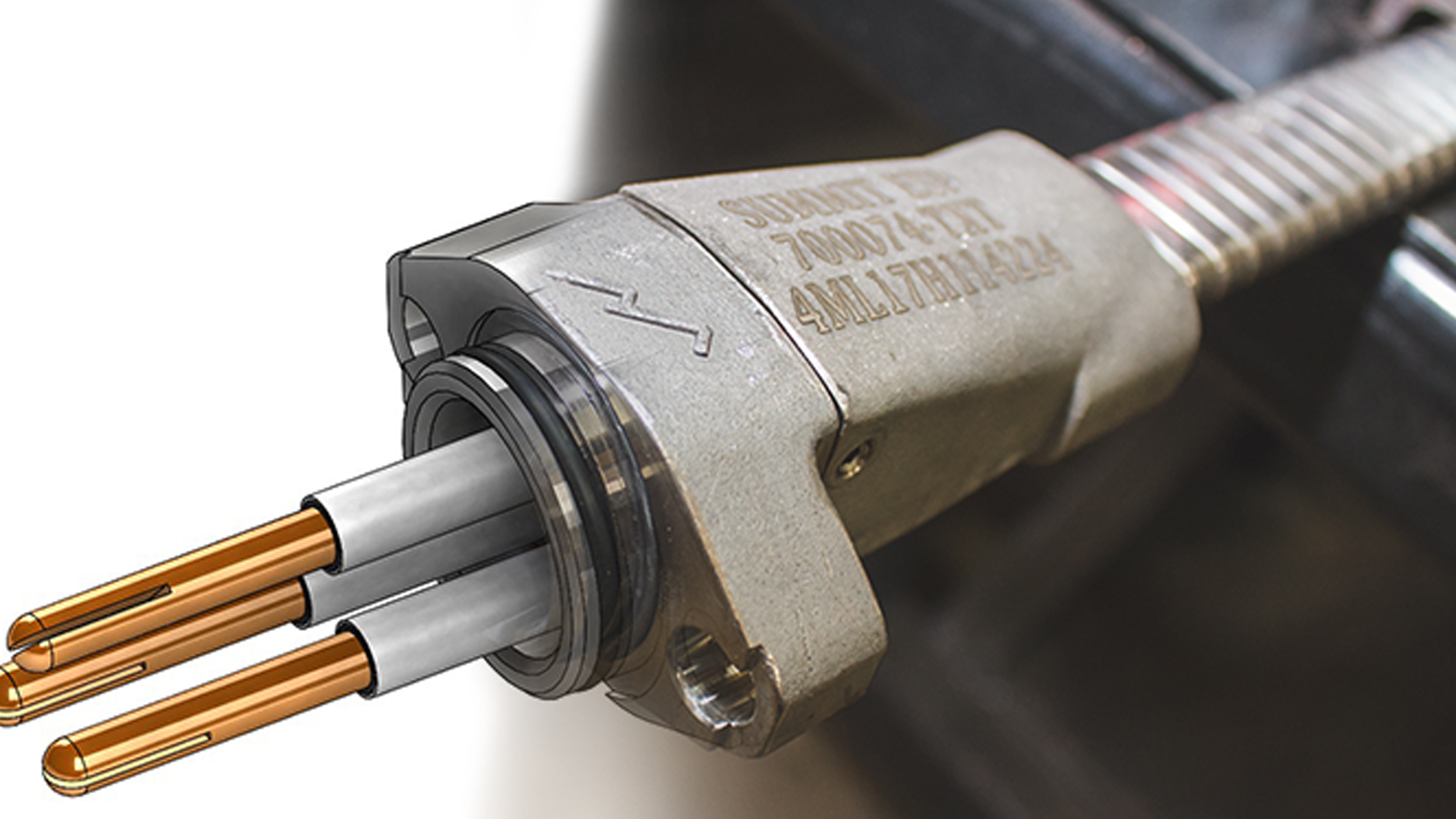

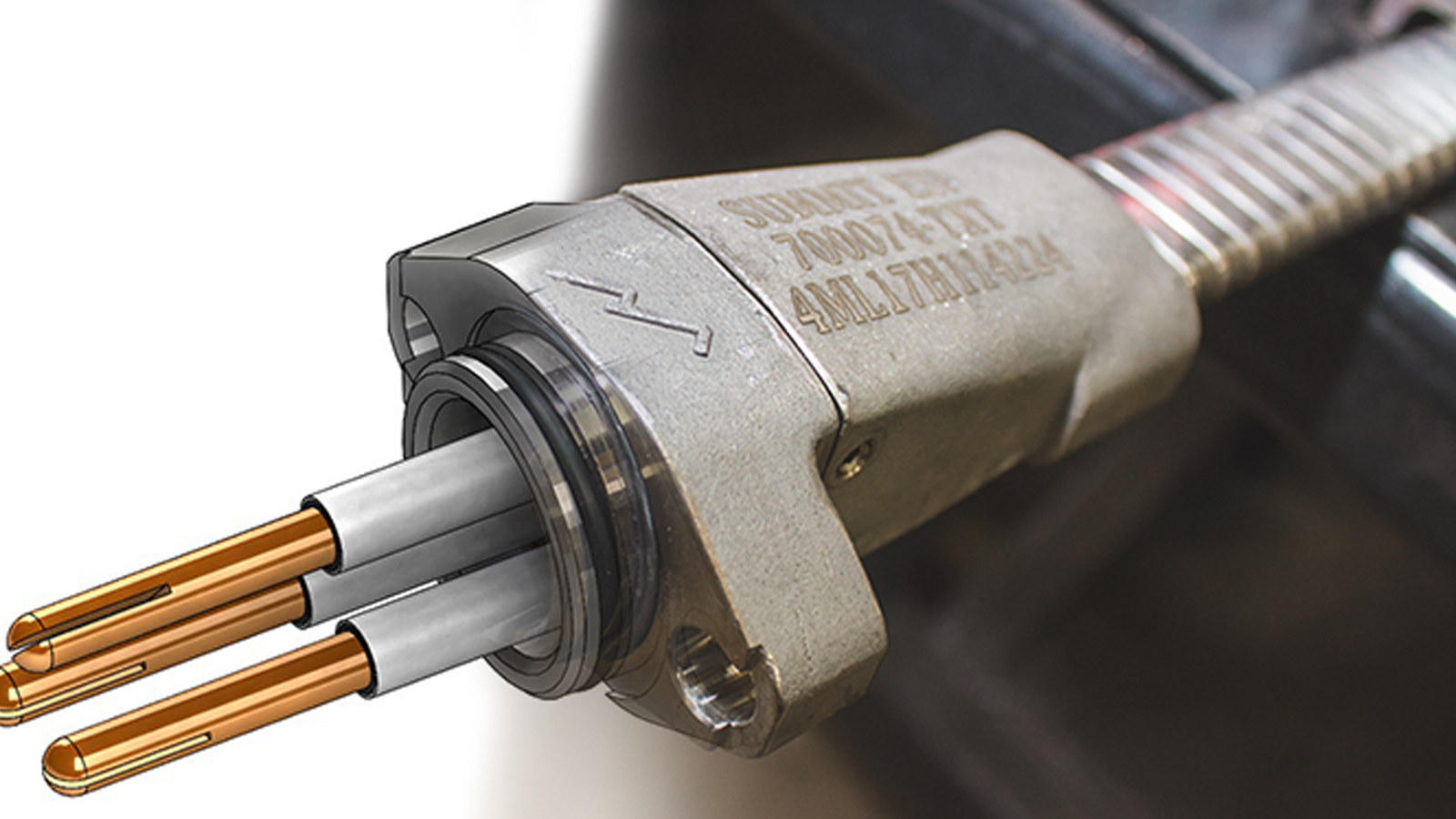

Summit ESP – a Halliburton service, proposed an ESP system with increased gas handling ability and electrical protection. The system included the Tiger Shark II pump and tandem Liberator gas separators for better gas handling and overall reliability. The key to this system is the Avenger® MLE, designed to withstand amperage fluctuations and electrical stresses created in high gas applications such as in the Montney formation. The Avenger MLE design reduces rubber in the seal by 90 percent and uses an O-ring to protect the seal. The industry leading reliability of this tape-in connection creates a 260% longer arc path versus the competition.

The operator has achieved greater drawdown and economic value due to higher electrical integrity of the Avenger MLE and its ability to handle extreme heat fluctuations from gas cycling in a high GOR environment. The Summit ESP system has been running for 341 days and still going, versus the competition’s system, which ran for 218 days.

SCF/BBL

consecutive run days at the moment of recording

Tiger Shark® electric submersible pumps are designed to adapt to changing well production, improving operating range and run life in harsh environments.

Avenger® MLE provides increased reliability in high-temperature, highly corrosive gassy wells.

Halliburton's Summit ESP® electric submersible pump systems increase run life and maximize production.