Search

Search

Search

Search

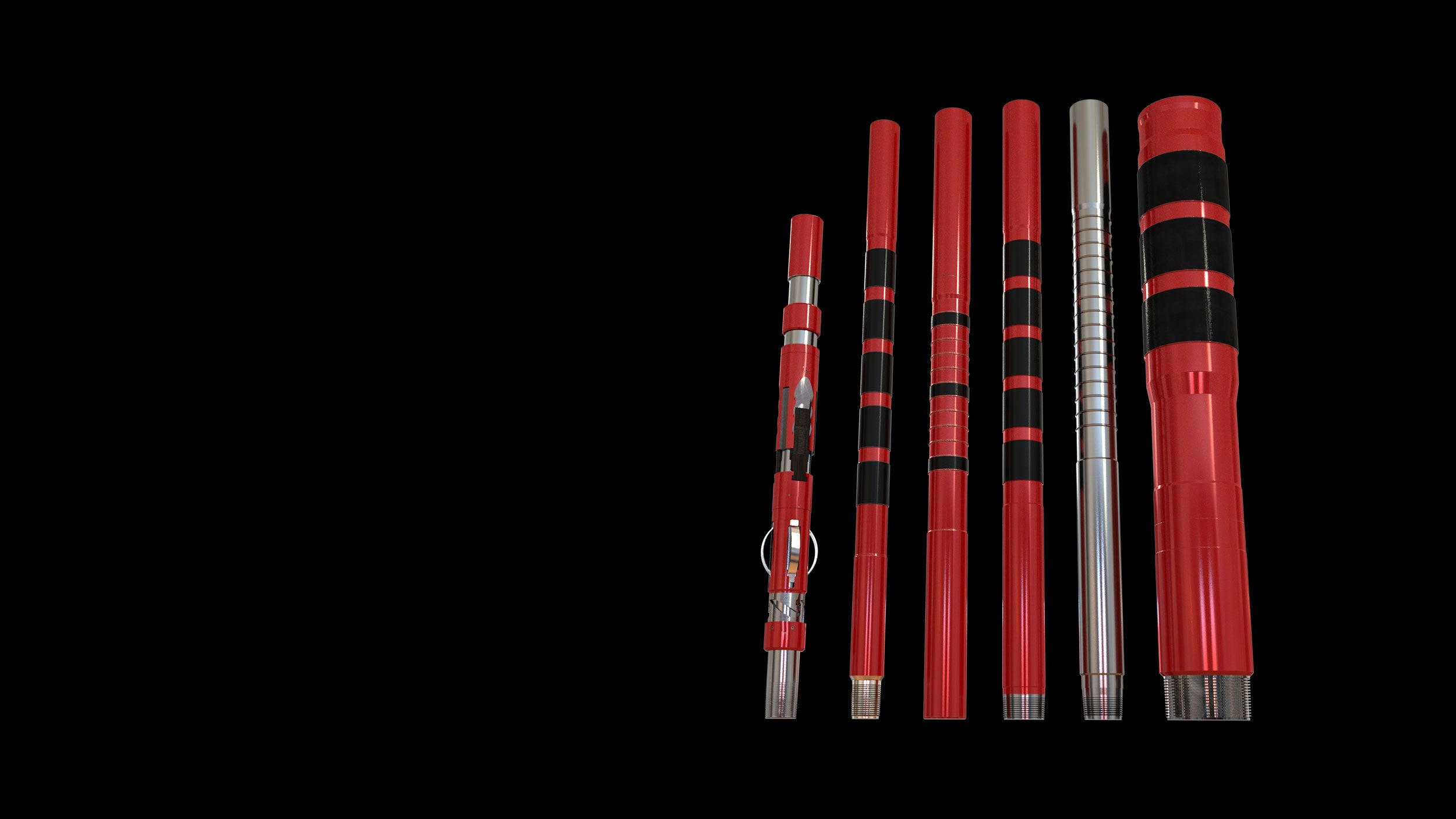

Pure metal-to-metal sealing technology overcomes challenging well conditions associated with elastomer seals

Download PDFDeep Water

Challenging wellbore environment

Sumatera

Pertamina Hulu Energy (PHE) Offshore South East Sumatera (OSES) is a state-owned national oil company in Indonesia that operates in the offshore area of southeast Java. This operator drilled its first well in this field in 1987, which is currently considered mature. The field presents challenging conditions, such as severe fluid loss during drilling and water breakthrough.

Halliburton identified a potential opportunity in this difficult geological formation where a conventional liner hanger (CLH) would be limited. In 2021, Halliburton introduced the VersaFlex® expandable liner hanger (ELH) system to the operator, and these systems are now installed in 14 of their wells to date. Despite the challenging well environment, the VersaFlex ELH has consistently performed without flaw and has never failed to meet job requirements since the first installation.

PHE OSES required a 7 × 9 5/8-in. VersaFlex ELH to be deployed in a perforated liner, along with hybrid swellable packers. During deployment, the operator encountered a massive loss rate of up to 1,250 bbl/hr (20.83 bbl/min) upon entry into the pay zone.

Despite the severe losses, the VersaFlex ELH was successfully deployed to total depth (TD) without issue and the integral liner hanger packer expanded as expected using a VersaFlex® ball set running tool. Setting success was confirmed in real time through a positive overpull. The running tool was retrieved with zero health, safety, environmental (HSE), or service quality (SQ) issues.

The successful installation of the VersaFlex ELH in this well set a record for ELH deployment in an environment with massive losses.

While drilling the 8 1/2-in. openhole section, upon entry into the pay zone, a loss rate of up to 1,250 bbl/hr (20.83 bbl/min) was recorded, which led the operator to proceed with blind drilling.

Deployment of a liner hanger system to a setting depth of 6,015 ft MD while managing a loss rate of 1,250 bbl/hr (20.83 bbl/min) requires a thorough risk assessment. Under the assumption the string is filled with fluid and the annulus is empty, differential pressure during the ball drop could increase the risk of lower setting pressure during expansion.

To maintain the annulus column, PHE OSES also attempted to fill the backside with seawater as much as possible while tripping in, which achieved rates up to 1,300 bbl/hr. These high rates could present the risk of swabbing the rubber element with traditional CLH systems.

The VersaFlex® ELH is a reliable system for this application. Its design, which features bonded elastomers and extrusion rings, effectively mitigates swabbing issues. With no moving parts, slips, or cages, the simple design of the VersaFlex ELH helps eliminate the risk of presetting the liner hanger/packer, particularly in massive loss environments—an issue that could be encountered with a CLH.

Halliburton worked closely with PHE OSES to address all risks associated with the operation beforehand. Competent field personnel executed the job without deviation from the approved wellsite instructions.

successfully reached and ELH system expanded

HSE issues

SQ issues

Halliburton successfully deployed the VersaFlex ELH system to TD with zero HSE or SQ issues. The system was set using a VersaFlex ball set running tool, and the expansion process was indicated. An anchor test was performed, and the running tool was released as designed and successfully retrieved.

In scenarios with massive well loss where CLH systems might fall short, the VersaFlex ELH design offers a robust barrier.

Through collaboration and continuous improvement, Halliburton delivered a reliable, engineered ELH solution to enhance efficiency and minimize CAPEX costs for the operator through optimized inventory assets.

The VersaFlex ELH can accommodate various wellbore conditions, which makes it a versatile choice for diverse drilling scenarios, particularly in environments prone to massive well loss.

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications