Search

Search

Search

Search

Project-specific, high-pressure subsurface safety valve meets operator requirements for major subsea gas well campaign

Download PDFProvide a gateway for new supplies of energy into Europe

Caspian Sea

Following the discovery of a significant gas field in the Caspian Sea, a major operator began planning of a large, complex subsea gas well project that would provide a gateway for new supplies of energy into Europe. The 18-well campaign necessitated a bespoke completion design, with a project-specific, deep-set subsurface safety valve as one of the most critical components.

As the preferred supplier, Halliburton worked with the operator to design and develop the various high-end intermediate and upper completion components, which included the subsurface safety valve.

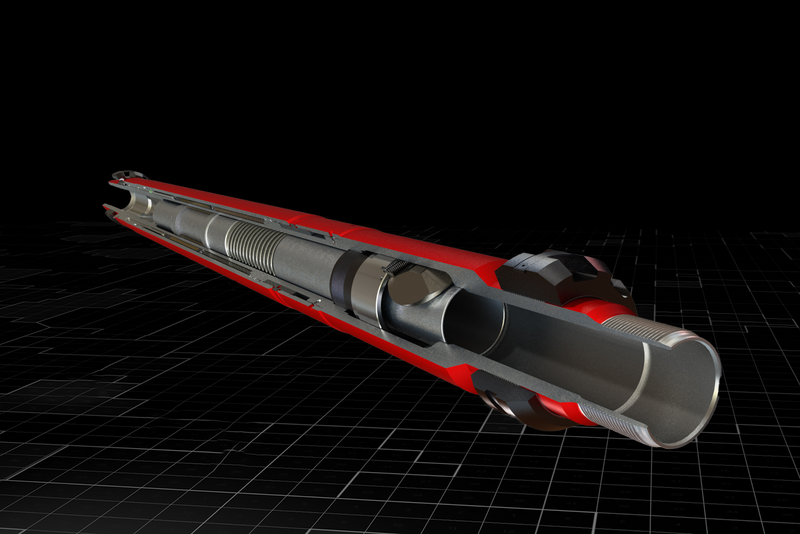

A setting depth of approximately 2000 meters (6,561 feet) was required to help ensure safety valve placement below the wax line and reduce the risk of hydrate problems during the life of the well. Conventional deep-set subsurface safety valves that utilize a pre-nitrogen, dome-charged, depth-specific system have proven problematic in other regions. The operator wanted to explore a more reliable subsurface safety valve concept to meet the demands of the prolific gas-producing subsea wells.

Halliburton closely collaborated with the operator and shared information and experiences from similar projects in the area to understand the reservoir and geographic challenges. The DepthStar® subsurface safety valve was identified as the ideal platform to meet the operator, well and project requirements. The DepthStar subsurface safety valve was already in use in other parts of the world but not in the size, pressure ratings or validation levels required. A development project commenced to take the existing design to the next level and meet not only the project-specific requirements but also the latest, highest industry standards and validation levels.

well subsea gas project

psi DepthStar® subsurface safety valve

14A V1 validation grade

Halliburton successfully designed, developed and validated the project-specific DepthStar subsurface safety valve to API SPEC 14A, 12th edition requirements and delivered the valve on time to meet the first phase of the completion installation program. The team installed the first 18 off valves successfully and brought the wells online, with the DepthStar subsurface safety valves fully functional with zero issues. Since the initial development, the valves have been updated to API 14A V1 validation grade, which reemphasizes the quality and longevity of the valves.

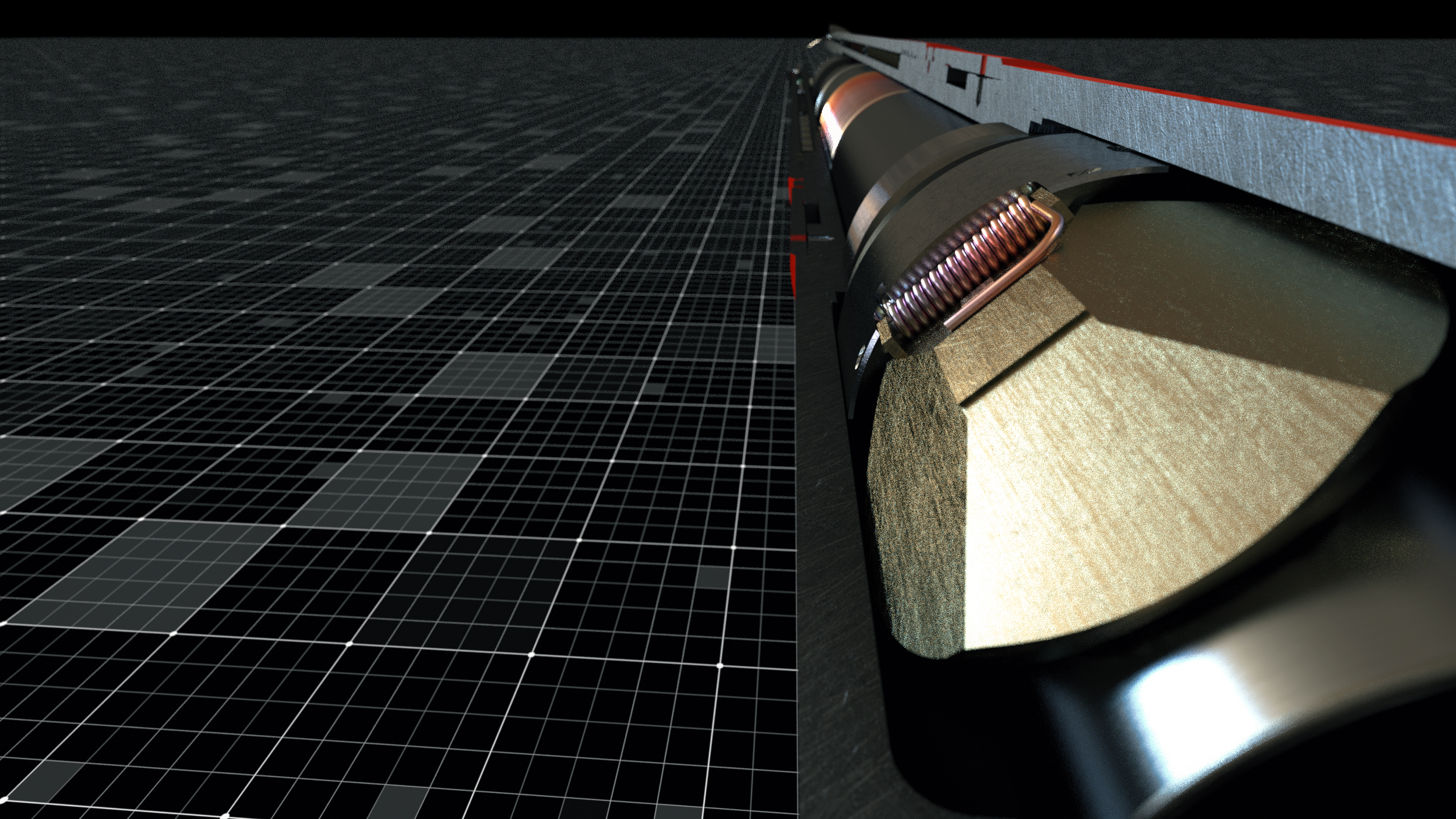

The DepthStar subsurface safety valve provided an ideal solution for the subsea wells because it can be operated with a low-pressure (5,000-psi) control system that can potentially save the operator millions of dollars. Its non-tubing, pressure-sensitive design enables an almost limitless setting depth and requires no depth-specific setup, unlike competitor nitrogen dome charge type offerings. The valve provides 100% metal-to-metal sealing within the tubing bore, with the piston actuator, etc. fully isolated and no moving seals exposed to the well environment. This helps eliminate the risk of possible gas migration in the control line, extends the valve life and increases reliability and safety.

In addition, the DepthStar subsurface safety valve includes a secondary line that is used to balance the hydrostatic forces of the control fluid acting on the operating piston. This secondary line can also be used to hydraulically exercise the flow tube in the event it becomes inoperable due to well conditions. The valve’s magnetic coupler provides a jar-like action during coupling/decoupling, which assists in debris dispersion, while incorporation of a sprung nose, flow tube design simplifies valve opening and provides a significant advantage in remote subsea wells.

Subsurface Safety Valves

The DepthStar® tubing-retrievable safety valve (TRSV) is a revolutionary concept in the realm of surface-controlled subsurface safety valves

Download Data Sheet

Helps to eliminate setting depth constraints, increase reliability, and reduce capex.