Search

Search

Search

Search

Cruzer™ rolling element technology helps reduce average on-bottom time to drill the curve by 43 percent.

Download PDFUnconventional

Achieve higher ROP while drilling the curve in horizontal well.

Williston Basin

In the unconventional horizontal wells of the Williston Basin, where performance standards are well defined, the Cruzer™ depth-of-cut rolling element has established a new benchmark for one operator—slashing the average on-bottom time to drill the curve from 12.4 hours to just 7.12 hours.

Already used successfully on more than 50 unconventional drilling projects in the Williston Basin, Cruzer technology is designed to increase toolface control without reducing drilling efficiency. In this case, the operator had drilled multiple wells from the pad over the course of a year, using competitor bits that yielded an average 12.4 on-bottom hours to drill the curve, including a single best performance in which the curve took 9.1 hours. The introduction of Cruzer technology delivered immediate improvement over offsets, with an initial application of an 8-3/4 inch GeoTech® GTD55DCU bit incorporating Cruzer technology drilling the curve in only 7.75 on-bottom hours, and a subsequent best performance taking just 4.9 hours. Overall, Cruzer technology reduced the average on-bottom time to drill the curve by 43 percent.

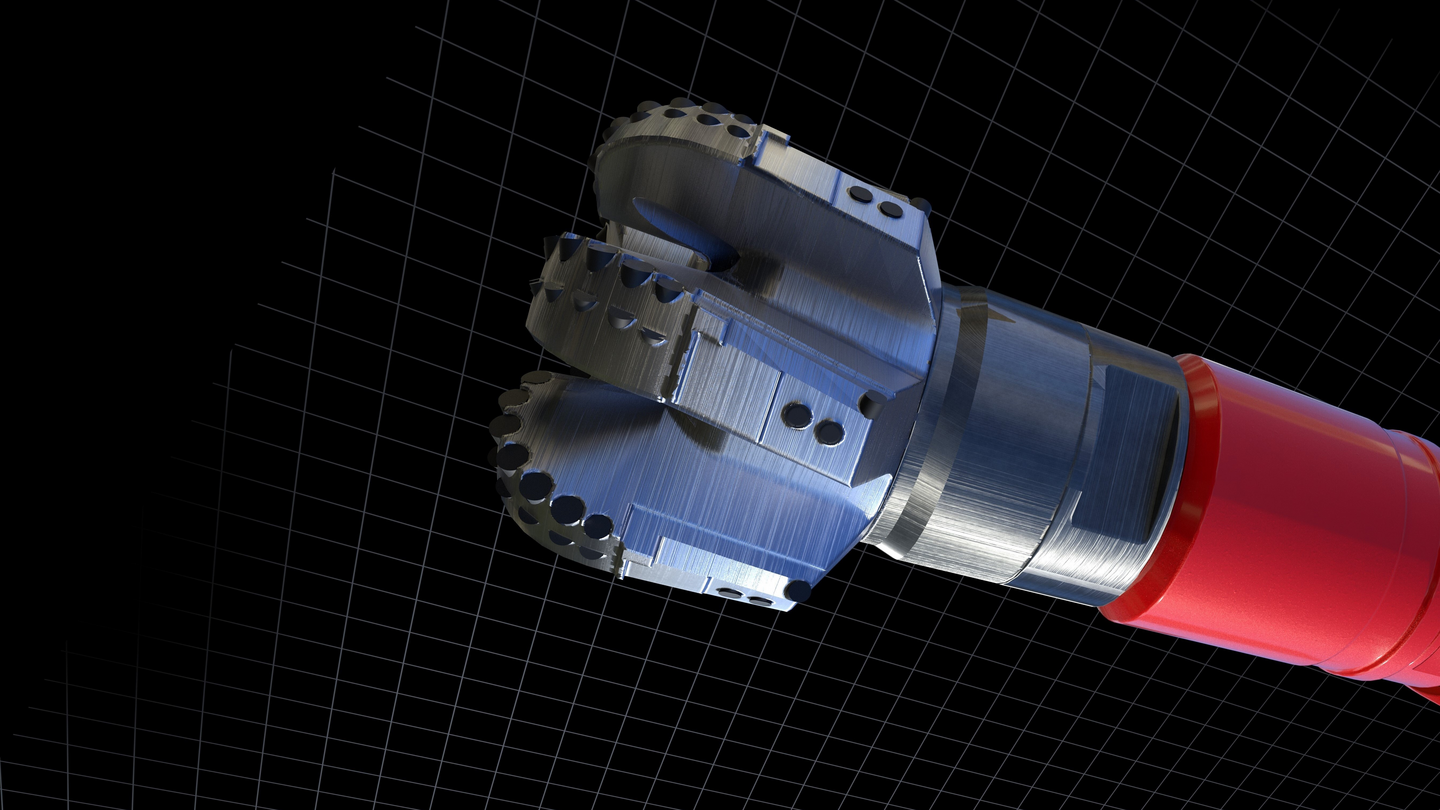

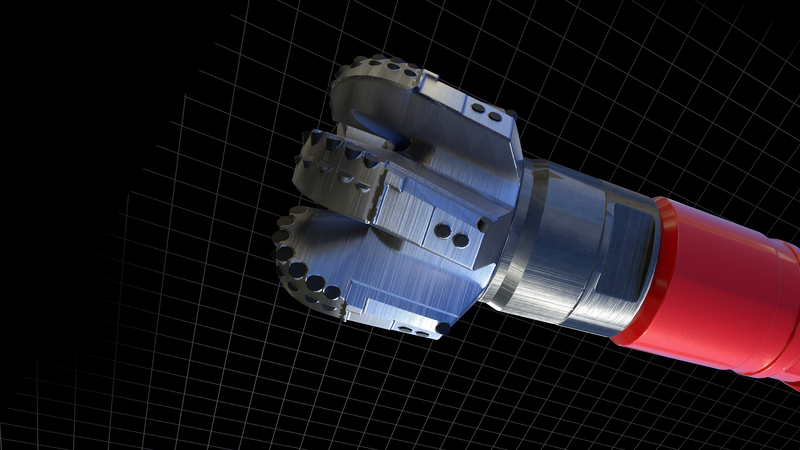

Developed to control the depth-of-cut without taking energy away from the cutting structure, Cruzer technology helps maximize penetration rates while delivering better toolface control, thus ensuring that intervals are drilled consistently on target. The depth-of-cut control (DOCC) rolling element reduces PDC bit over-engagement due to formation changes or vibration without compromising cutting energy, so all available torque can be used by the cutters to shear rock for more efficient drilling, while toolface control is enhanced by the consistent depth-of-cut. For this Williston Basin application, the operator realized the following benefits:

Delivering faster ROP with greater toolface control, Halliburton drill bits that incorporate the Cruzer DOCC rolling element easily overcome the directional challenges of complex well geometries like those in the unconventional horizontal wells of the Williston Basin. A design option for Halliburton high-performance PDC bits, the rolling DOCC element improves depth-of-cut control while dramatically reducing the energy loss by the element, thereby greatly enhancing drilling performance in a wide range of applications.

The Cruzer™ depth-of-cut rolling element increases tool face control for improved drilling efficiency and directional control.

GeoTech® matrix and steel body drill bits are customized to deliver performance across all drilling applications.