Search

Search

Search

Search

Longest, fastest well in the area was drilled compared to offset wells while capturing in-bit data to maximize learning curve and improve drilling dynamics

Download PDFDeepwater

Gain better insight into a 90% unmapped block and field

Caribbean

Providing a customized drill bit and engineered solution, Halliburton Drill Bits and Services helped an operator in Guyana level up its drilling performance during a deepwater exploration project. This set a new performance benchmark for the area, providing measures to enhance future drilling operations.

With only 10% of its block mapped to date, an operator in Guyana wanted to gain better insight into the block and field. The challenge was creating a reliable bit design that could achieve TD in a single run. Because previous drilling operations deployed only bits without sensors, no accurate data at the bit had been recorded.

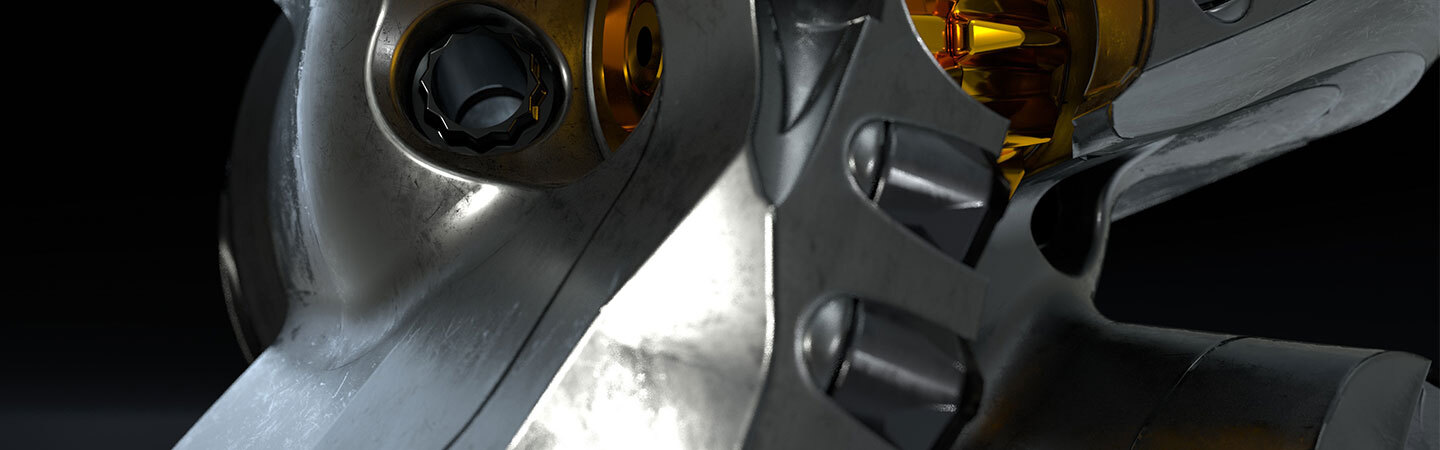

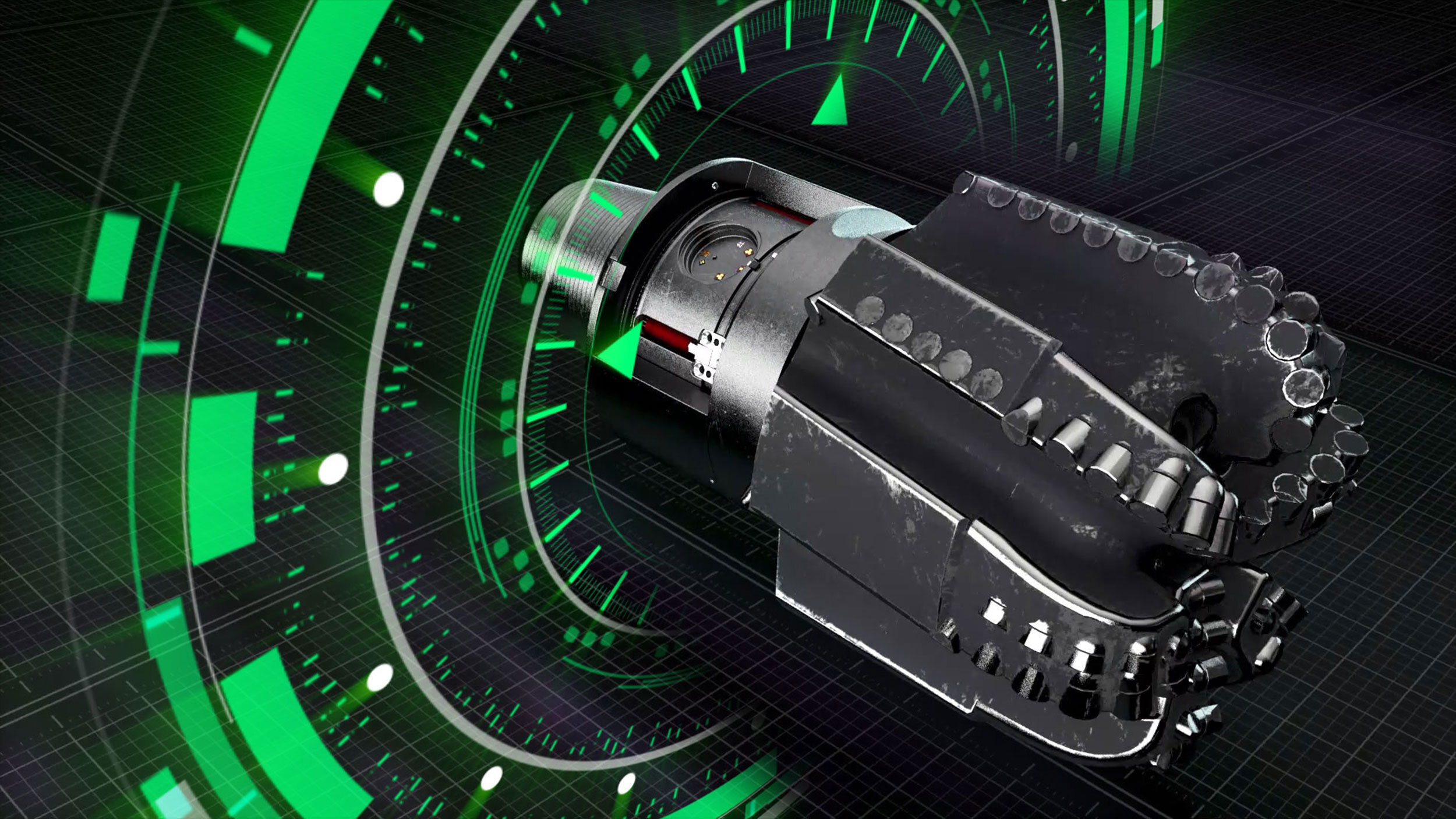

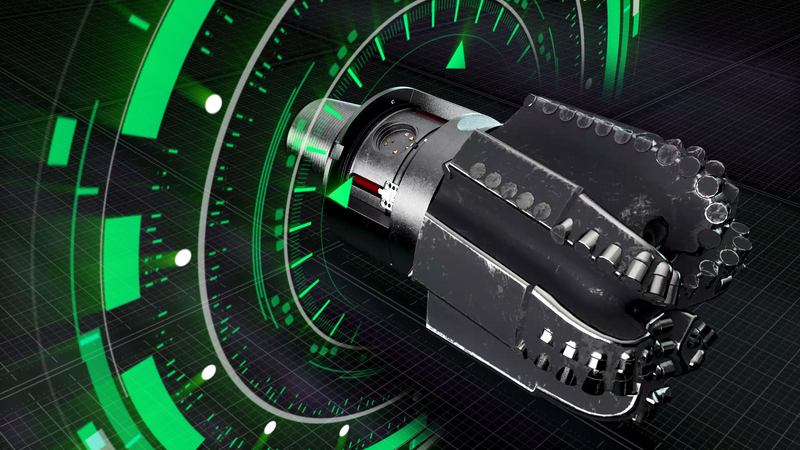

Halliburton deployed Design at the Customer Interface (DatCISM) services, which combine application intelligence, local expertise, superior execution, and business development to provide a customized drilling solution for this application. An 8-1/2 in. GT75WMKF GeoTech® bit equipped with Cerebro Force™ in-bit sensing was designed to capture weight, torque, and bending measurements directly from the bit. This information provides the operator with a clearer picture of the downhole drilling environment, allowing room for future design improvement to drilling parameters or bit designs.

Hours of data capture

Drilled in one run

ROP

We set a new benchmark during this deepwater exploration operation, drilling the longest and fastest well in the area compared to offset wells while capturing in-bit data to maximize the learning curve and improve drilling dynamics awareness. This information can be used to enhance future well performance.

An 8-1/2 in. GT75WMKF GeoTech bit drilled 709 m with 67 m of HDI in one run at a total ROP of 16 m/hour while logging 140 hours of data capture. TD was reached in a single run while Cerebro Force in-bit sensing provided a complete report on the findings. S&S vibrations were identified during the drillout operation, which was not previously considered by the directional drilling company, as it had never implemented gyroscope sensors on the BHA. HFTO vibrations were also recorded; upon analysis, this was attributed to limestone stringers after reviewing mud log reports and logging records. The operator and directional drilling company now have a road map for an offset exploratory well that will permit more efficient, safer drilling, which can help mitigate damage to downhole tools and prevent unnecessary trips during future drilling operations.

The Halliburton Cerebro Force™ in-bit sensor improves drill bit performance, giving operators data needed to optimize use for the length of a run.