Search

Search

Search

Search

16 e-cd™ connections successfully made while running liner

Download PDFDeep water

Maintain circulation to safely reach TD for running liner in hole

Southeast Asia

An operator wanting to run a liner through a narrow operational window formation offshore Southeast Asia had suffered severe losses drilling a near-by well. To achieve a positive outcome, it was necessary to improve circulation techniques and find a novel engineered solution for accomplishing several downhole operations, including cementing and coring. Halliburton had already used the e-cd™ continuous circulating system in other scenarios with this client—and even discussed pumping darts through the e-cd subs—but had not implemented the advanced procedure to date.

Ongoing hole cleaning and cuttings movement were crucial to safely and seamlessly reach total depth (TD) for running the liner in hole without any pack-off or stuck liner incidents. This would require maintaining circulation during pumps-off events, in particular. Also, in order to drill through a narrow operational window formation, constant bottomhole pressure would have to be maintained during drillpipe connections. All this while maintaining wellbore stability and hole cleaning for successfully running liner to bottom in extended reach sections was crucial.

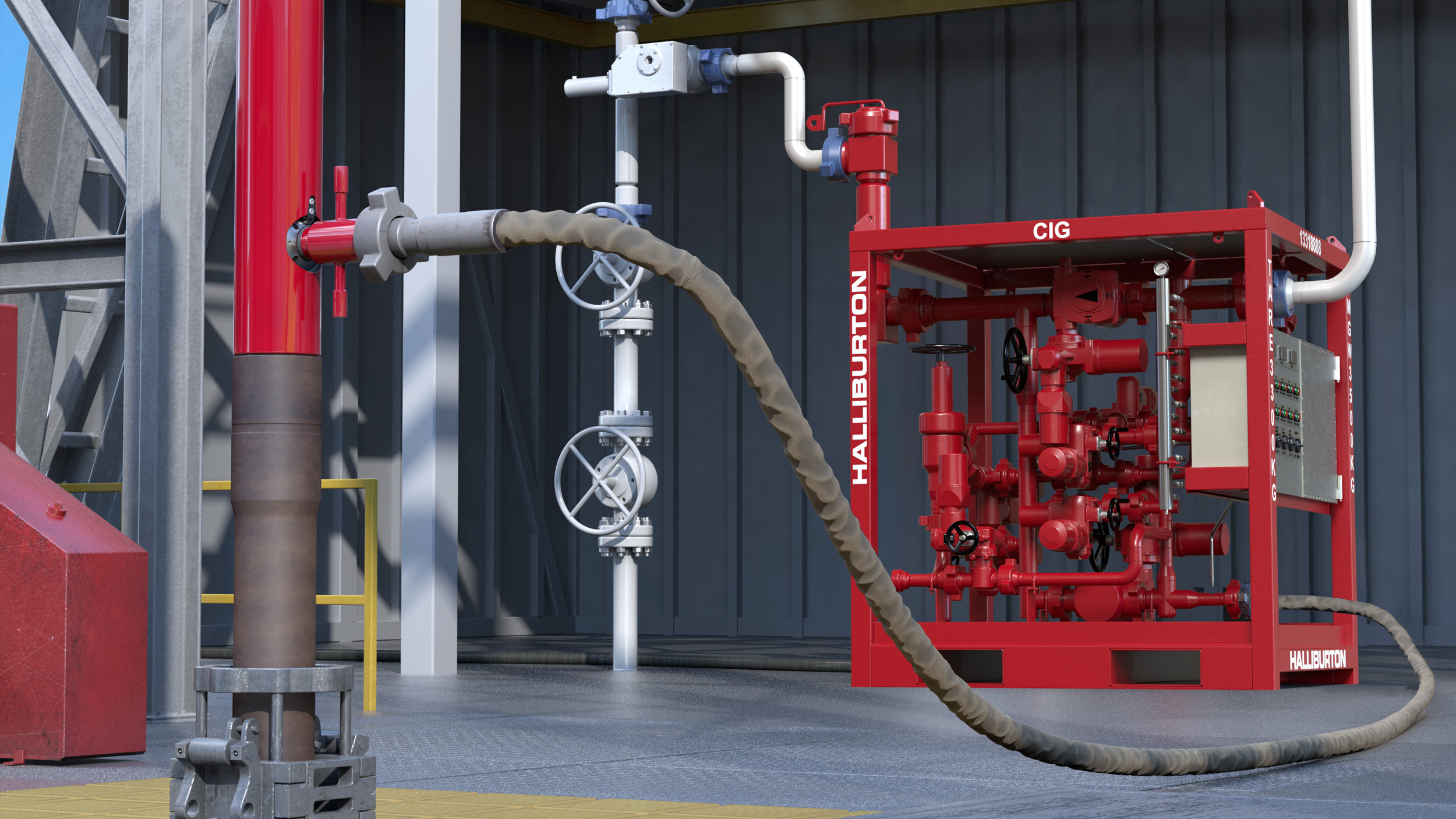

The Halliburton e-cd™ circulating device was utilized in the drillstring to provide continuous circulation and hole cleaning during the drillpipe connection process. In this case, the e-cd™ electric equipment was also implemented to allow remotely controlled operations that not only increased efficiency and cost-effectiveness by minimizing connection time but also assured safe unmanned operations. Finally, the use of a liner activation dart was employed, along with a guide sleeve to ease the dart pumping process.

Near balance mud was used for drilling to minimize downhole losses and extend section TD. The liner was run first using the e-cd™ subs to provide continuous circulation. Then, the darts were dropped through the drillstring, followed by cementing the liner with the e-cd™ subs still in place. The e-cd ™ continuous circulation was deployed over three sections, performing 130 e-cd™ connections during drilling, coring, tripping, and running liner operations.

In total, 16 e-cd™ connections were made while running the liner. This represents Halliburton’s first-ever e-cd™ application in which darts were pumped through e-cd™ subs or a liner was run using e-cd™ continuous circulation methods.

e-cd™ connections made, while running liner

Success rate of e-cd™ connections

The Halliburton e-cd™ circulating device is an Eni-patented system used in managed pressure drilling operations