Search

Search

Search

Search

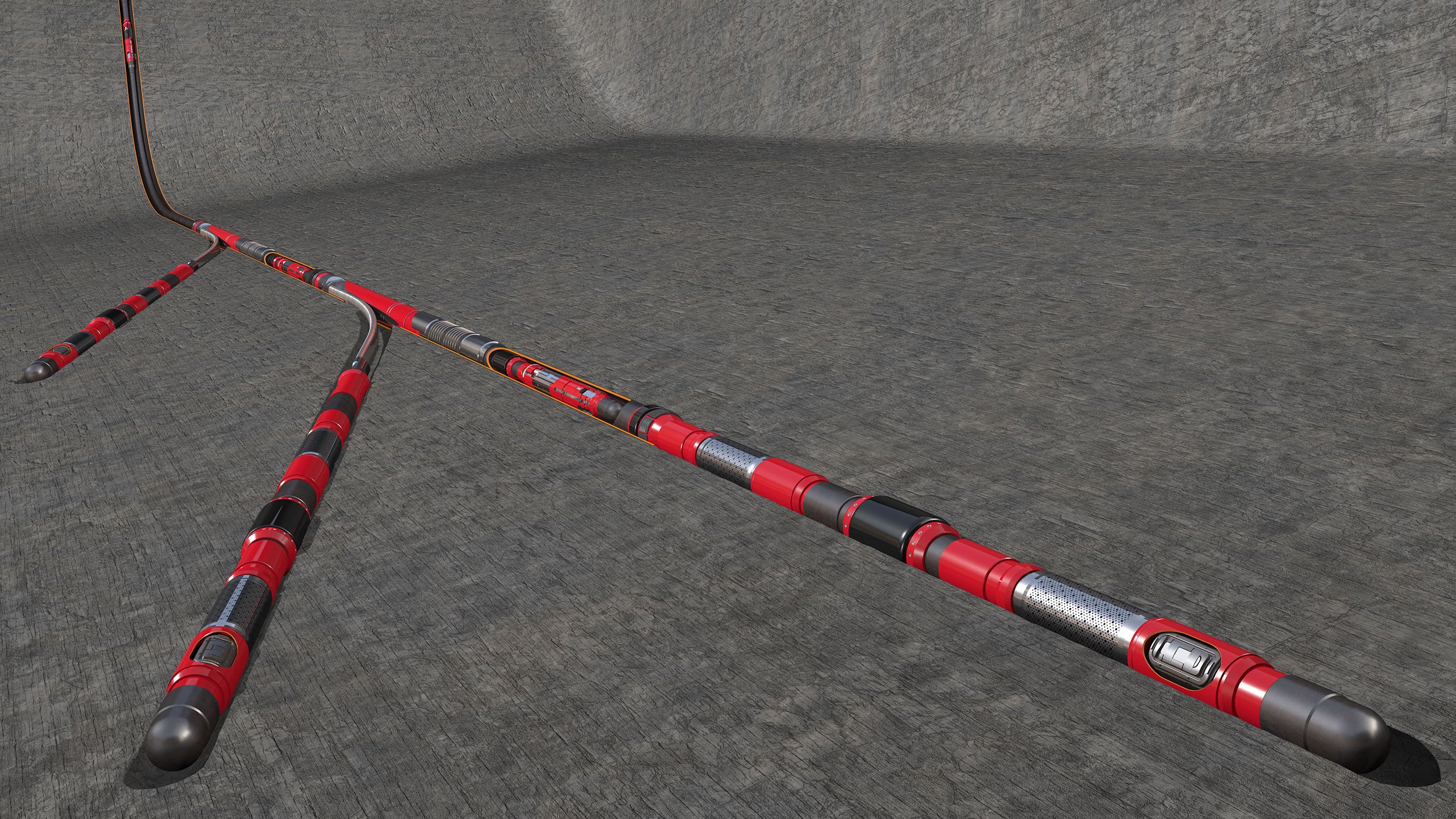

Expandable metal-to-metal anchor system provides reliability and versatility to multilateral installations

Download PDFMature Fields

Provide an anchor system to reliably position a junction at the desired depth

Halliburton has installed its 50th MLT XtremeGrip® Anchor system. The first system was installed in 2019, and the system has since been utilized for a variety of multilateral well solutions. A focus on retrofit and re-entry multilaterals has driven utilization.

The lack of wellhead slots available to drill new wells challenges many operators to introduce new well designs and technical solutions. Multilateral technology allows multiple targets or enhanced reservoir contact to be achieved through a reduced number of slots compared to traditional wellbore construction methods.

The foundation for multilateral well construction is a reliable mainbore anchor point with orientation control, which provides the service tool a landing point from which a casing exit window is milled, and a lateral leg drilled and completed. The reliability of the anchor has a significant impact on the success of the installation. Previously used anchor systems had limited tensile, torque, and inside diameter (ID) capabilities that restricted or limited junction construction.

Operators sought a reliable anchor to confidently install retrofit and re-entry multilateral wells. To establish a foundation for the retrofit and re-entry capabilities of this branch, an anchor was required to provide a broad scope to position a junction at the desired depth and provide orientation control to enable lateral construction.

Halliburton developed an expandable anchor packer based on an existing field-proven expandable liner hanger design. The XtremeGrip MLT system provided a broader scope to position and orient the packer at the desired depth to begin lateral construction and provide completion flexibility. The goal was to maximize tensile, torque, and ID capabilities and minimize rotation during the orientation of the junction construction operations.

The increased tensile rating of the system allows the deployment of screens, slotted liners, or cemented liners directly below the XtremeGrip® MLT Anchor system. This eliminates the requirement for a separate trip with a liner deployment system.

The integral self-orienting, depth-control mechanism allows for both the casing exit system and the junction to be installed without the need for rotation and/or multiple depth confirmation attempts. The large packer ID permits compatibility with a wide range of field-proven multilateral and completion systems.

trip time by deploying screens and slotted liners

installation of XtremeGrip MLT anchor system globally

time for operator from purchasing additional equipment

With the successful deployment of the reliable XtremeGrip MLT system, the operator saves trip time by deploying screens, slotted liners, or cemented liners below the anchor. The XtremeGrip MLT system also saves the operator from having to purchase additional equipment for a separate screen deployment. Additionally, the system allows for larger IDs and enables the use of Intelligent Completion equipment, which provides independent flow control for the main bore and lateral production. The XtremeGrip MLT system ultimately enables operators to save rig time and costs, and to successfully extend the production life of new and mature wells.

Expandable liner hangers

The XtremeGrip MLT system is designed for multilateral wells in both offshore and onshore applications. It features an integral self-orienting profile that ensures positive depth and orientation control.

Download Data Sheet