Search

Search

Search

Search

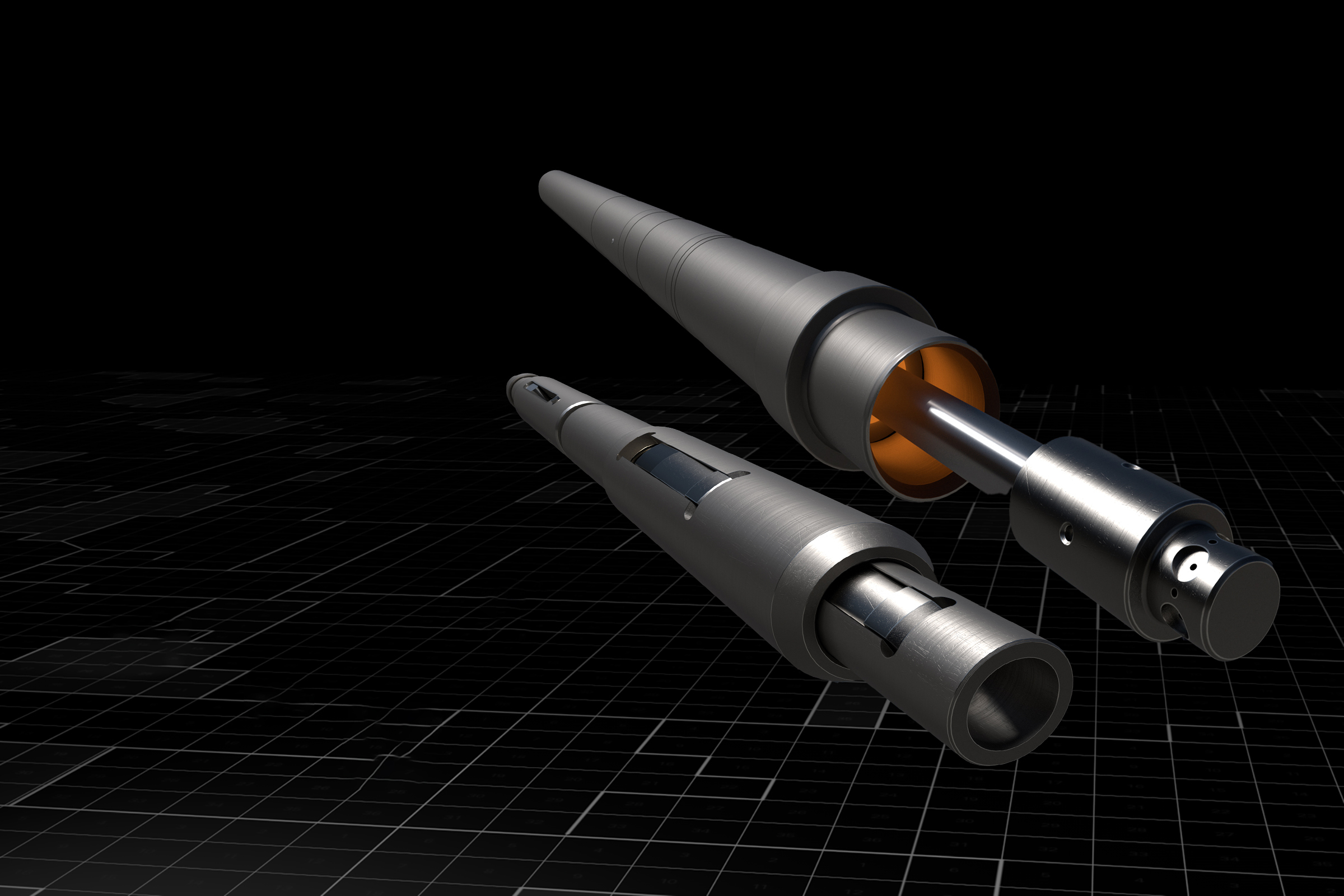

Otis® X® and R® running tools

Otis® X® and R® running tools are used to set Otis X, XN®, R, RN®, and RQ lock mandrels in their respective Otis landing nipples. These tools are designed with locator dogs serving to locate the proper landing nipple and positioning the lock mandrel before locating and locking. By selecting the position of the running tool, lock mandrel keys can be placed in the locating or retracted position.

DPU downhole power unit

The Halliburton DPU® downhole power unit is a battery-powered, rig-safe, non-explosive electromechanical tool that expands well intervention capabilities. By generating a slow, precisely controlled linear force, the DPU tool optimizes settings and helps ensure maximum well completion performance, even in the most high-risk environments. With the advanced measurement system (AMS) for accurate depth control, the slickline-conveyed DPU tool performs reliable and flexible well intervention solutions beyond conventional methods.

The subsurface device (plug, packer, straddle) is attached to the DPU tool, which can be deployed on slickline, coiled tubing, or wireline tractor. The stroke length, setting force, and rate at which the force is applied during the setting operation are recorded in memory for later playback and quality-assurance purposes. The slow, controlled setting sequence maximizes sealing and anchoring of the wellbore device. When the designated setting force is achieved, the DPU tool separates from the subsurface device and is retrieved from the wellbore.