Search

Search

Search

Search

Revolutionizing fracture operations with automation and big data integration

Talk to an expertStimulation designs continue to demand higher rates, higher pressures, longer pump times, and increased sand volumes. Our innovative technologies, such as OCTIV® digital fracturing services, enable hyper-efficiency, reduce environmental impact, enhance service quality, and decrease personnel exposure.

The industry as a whole realizes fracture performance, well spacing, and cross-well behavior can inhibit improving recovery factors. We simplify the use of big data, providing unmatched visibility and control over fracture performance.

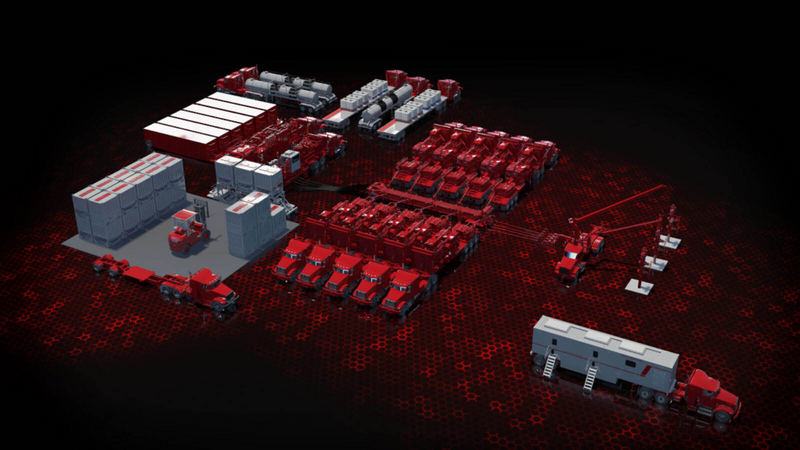

More than routine task automation, Halliburton’s fracture operations are digitally automated. With remote connectivity, we automate the spread to maximize performance and efficiency. We improve equipment reliability and operational efficiency by continuously monitoring equipment health and well conditions with thousands of sensors. Digital workflows streamline operations and connect field technicians with office decision-makers.

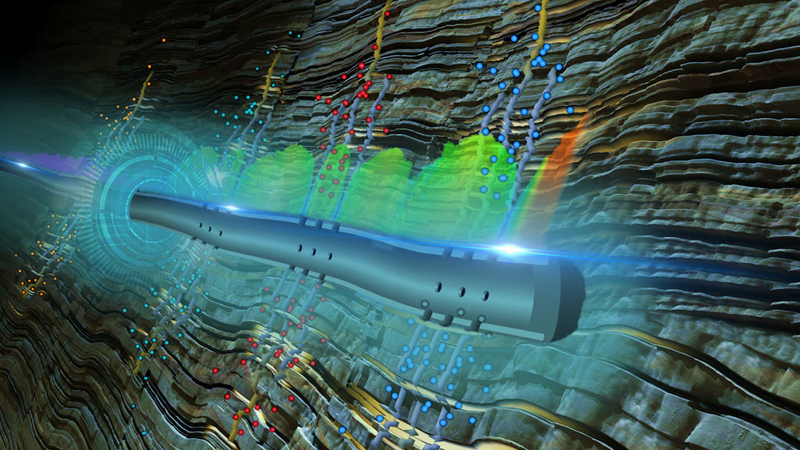

Data only generates value when it can quickly and confidently improve fracture designs to optimize economics and recovery. The challenge with unconventional shale is the variability of the rock. Typically, data is collected to find the best well placement. However, historically, little data has been gathered during fracture stimulation, even though this is when most subsurface changes happen. Halliburton simplifies dynamic big data by using their Sensori™ fracture monitoring service, which combines continuous data acquisition, advanced processing, and real-time visualization to optimize fracture designs and improve recovery.

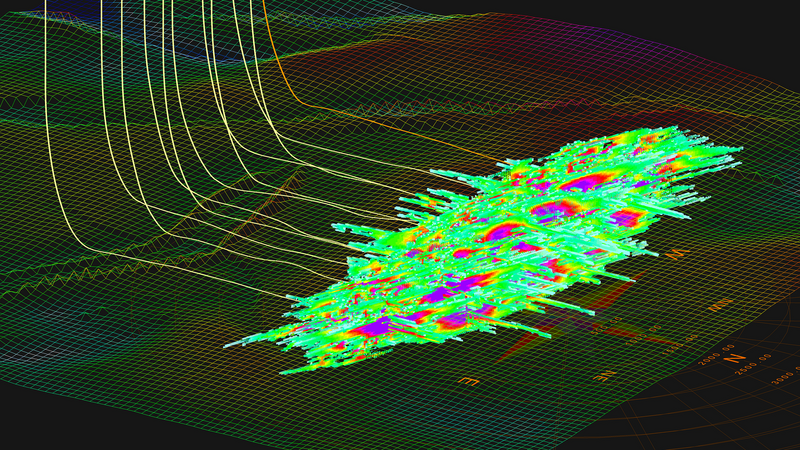

Halliburton’s stimulation portfolio provides near-well and far-field fracture monitoring services. This allows real-time integration, visualization, and analysis of subsurface fracture measurements across multiple well pads. Optimizing cluster design and stage lengths offers precise measurements of fluid distribution at each stage.

We use continuous data from distributed acoustic sensing (DAS), microseismic, and strain measurements to provide a detailed real-time view of fracture direction, growth rate, and shape. This helps identify when, where, and why frac hits happen.

Our stimulation platform combines insights for a full view of fracture performance. We integrate near-well and cross-well monitoring to provide a complete understanding of how stage-level distribution affects far-field response.

Fracture Monitoring

The Sensori™ fracture monitoring service combines non-intrusive technologies, advanced data acquisition and processing, and real-time answers into a single, cost-effective solution that empowers operators with unparalleled visibility and control over fracture performance.

explore sensoriHalliburton’s Excelerate® friction reducers portfolio is tailored to optimize stimulation treatment performance in a wide range of complex applications. When handling complex water quality, friction reducers enhance the interaction between frac water and fluid additives. This goes beyond conventional chemistry limits, reducing the risk of operational failures and lowering pumping costs.

We use advanced testing to recommend the best friction reducer for specific chemistries in real-world conditions. This ensures more efficient fluid flow and higher pumping rates.

Through testing, our technicians identify additive and chemical compatibility issues to mitigate undesirable fluid properties and operational challenges.

stimulation chemicals

Excelerate friction reducers are custom-designed to optimize stimulation treatment performance in a wide range of complex applications. When dealing with complex water quality, Excelerate friction reducers can help minimize the risk of operational failures and extended pumping costs.

explore excelerateWe engineer to outperform and deliver optimized stimulation solutions to improve efficiency, productivity, emissions, and safety in unconventional, challenging environments such as tight shale.

Halliburton’s SmartWell® completion systems set new standards for innovation, efficiency, and reliability in electric fracturing. By leveraging intelligent automation, digital operations, remote connectivity, and performance visibility, it optimizes equipment, enhances reliability, and increases job efficiency and pumping hours.

World Oil Podcast Episode

In this episode, we explore the latest advancements in fracture monitoring technology. Discover how our Sensori service simplifies fracture monitoring with easy-to-deploy, non-intrusive diagnostics that lower cost and complexity while providing continuous, real-time subsurface measurements.

Watch PodcastWorld Oil Podcast Episode

In this episode, we explore the latest advancements in electric fracturing technology. Discover how ZEUS services and innovative automation techniques are setting new standards for efficiency and reliability in electric fracturing.

Watch PodcastWorld Oil podcast episode

In this episode, we explore the OCTIV® digital fracturing services, which automates spread control, significantly improving consistency, efficiency, and reliability. Discover how OCTIV services optimize pump operations, reduce manual interventions, and extend equipment life.

watch podcastHalliburton’s stimulation portfolio enhances hydraulic fracturing, pinpoint stimulation, acidizing, near-wellbore cleanout, and conductivity endurance. It achieves hyper-efficiency by minimizing the impact of operational inconsistencies in downhole conditions, surface equipment, and personnel competency.

The Halliburton approach to fracturing maximizes surface and subsurface efficiency to optimize the value of your capital investment.

Halliburton provides scalable fiber optic sensing and real-time analytics that result in confident performance-enhancing adjustments to fracture designs.

GOHFER software is the premier hydraulic fracture software package on the market and is the right tool to drive value to the end users.

Providing superior chemical performance, optimized stimulation, and on-site support through cost-effective, enhanced production flow

Spend less time waiting and more time fracturing with Halliburton sand services that span sand acquisition, storage, transportation and delivery